Method for calibrating origin position of center axis of rotary table based on visual measurement

A central axis and visual measurement technology, applied in the field of measurement, can solve problems such as no solution, achieve the effect of improving measurement accuracy and efficiency, improving measurement accuracy and measurement efficiency, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

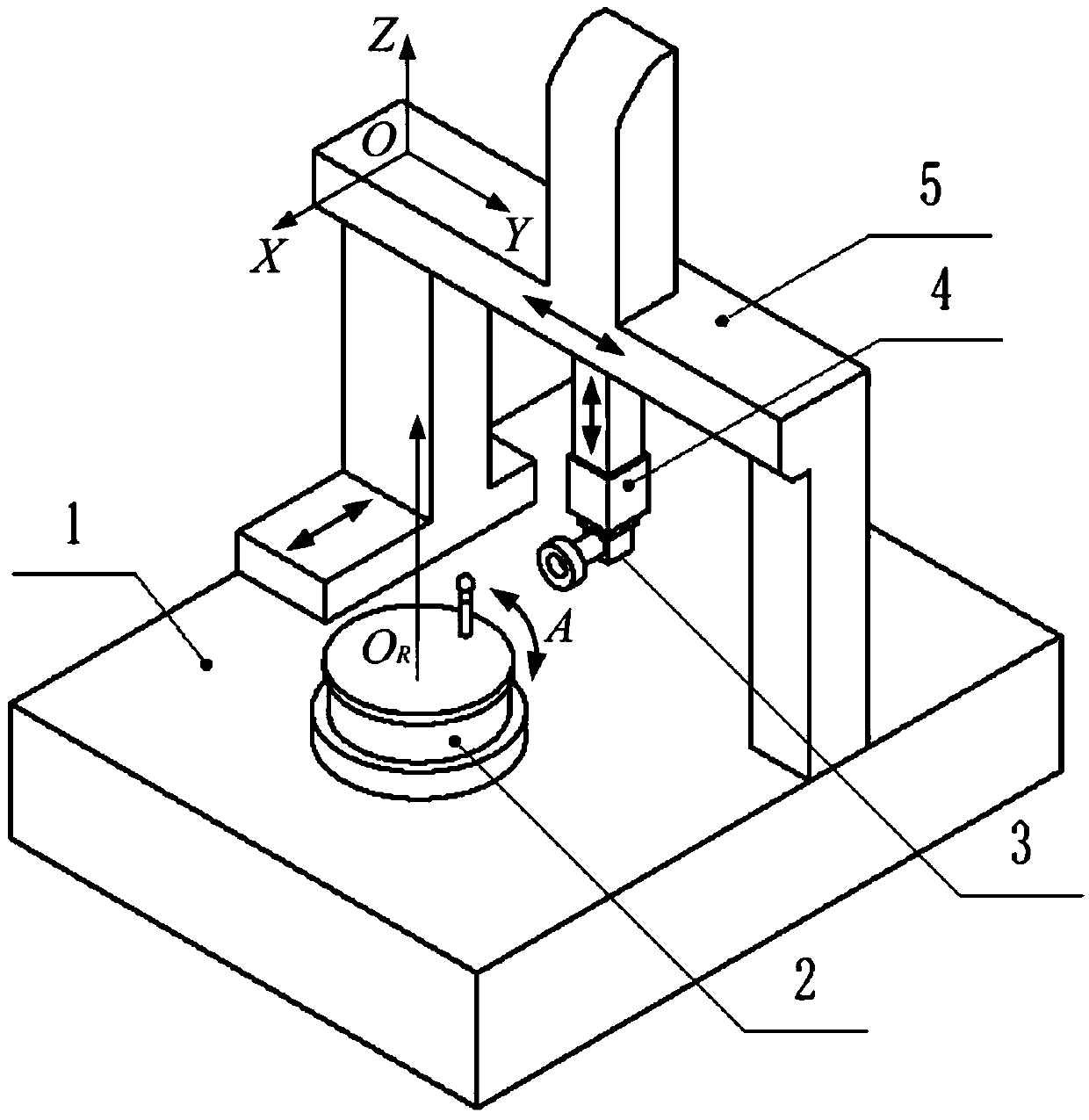

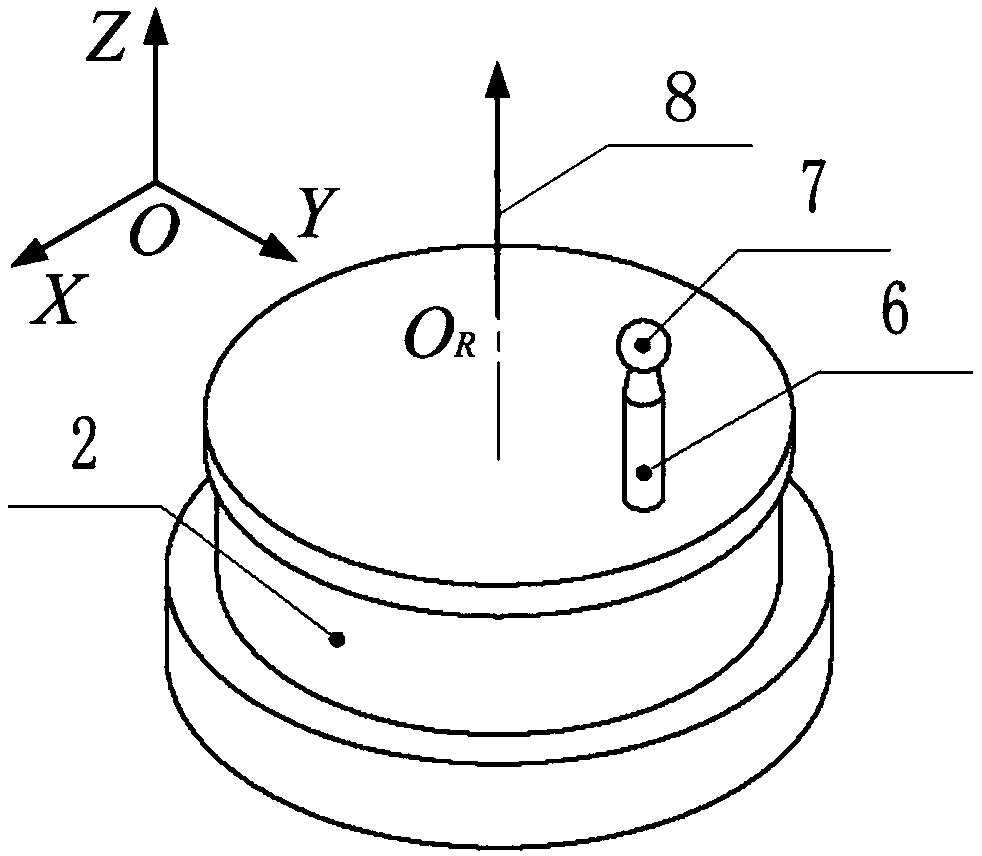

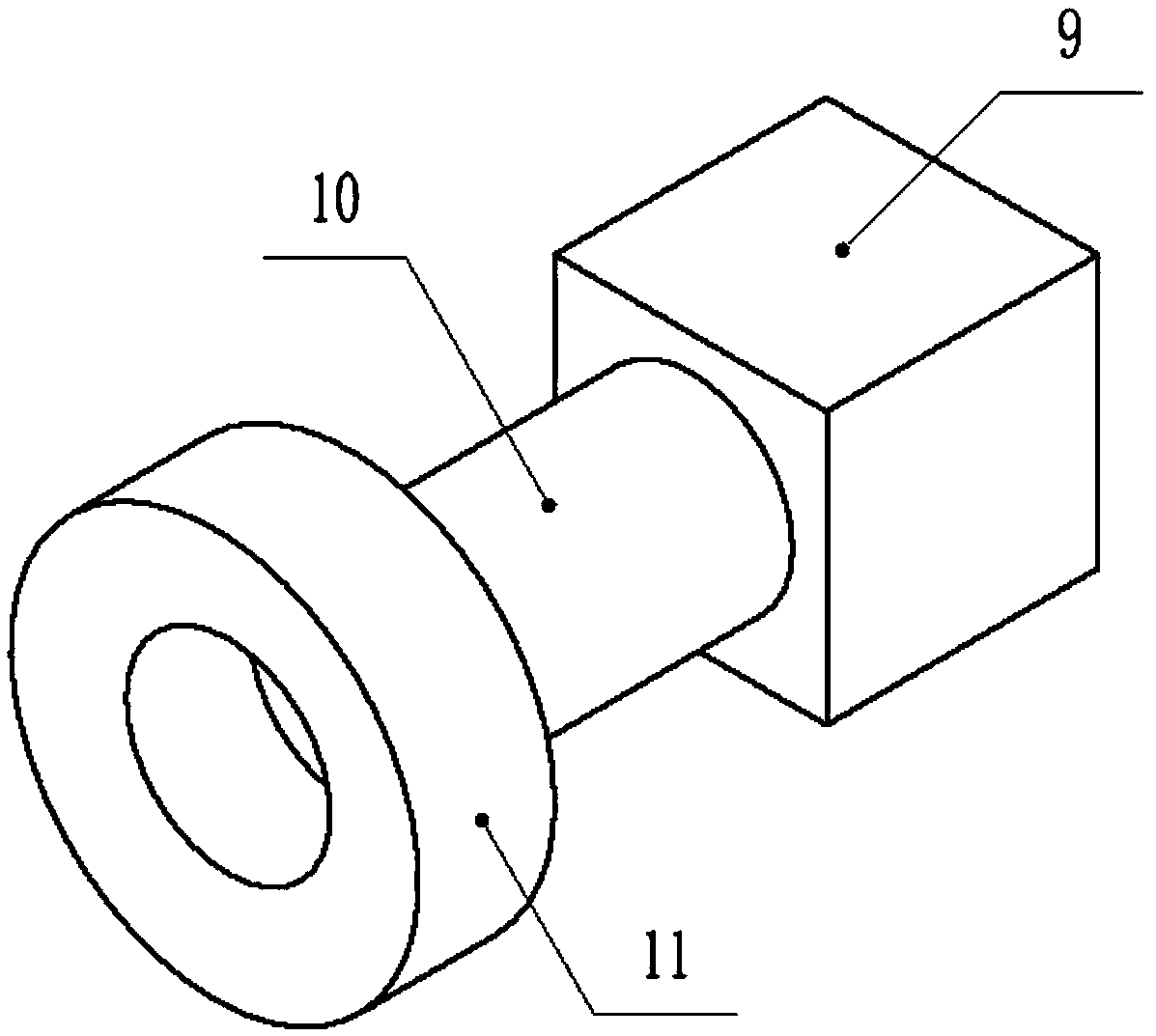

[0030] See attached Figure 1~5 As shown, this visual measurement device includes a workbench 1, a turntable 2, an image acquisition device 3, a camera mount 4 and a three-dimensional mobile bridge 5. Among them, the overall frame composed of the three-dimensional mobile bridge 5 and the workbench 1 is realized by the Pearl 1298 three-coordinate measuring machine produced by the Beijing Aeronautical Precision Research Institute. The workbench 1 is made of natural granite with good thermal stability, and After the upper surface is inspected by the grid method, the surface flatness reaches the 00-level standard. This type of three-coordinate measuring machine can produce linear motion in the three directions of X, Y, and Z, and each axis is equipped with air bearing guide rails and high-precision grating scales, so as to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com