Self-lifting 3D printer for wall of high-rise building and construction method of self-lifting 3D printer

A 3D printer, high-rise building technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of the stability test of the support column, affect the quality of the printed wall, interfere with the movement of the Y-axis beam and the lifting rod, etc. Reduce the test of wall strength, ensure the safety of printing construction, and ensure the effect of overall strength and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

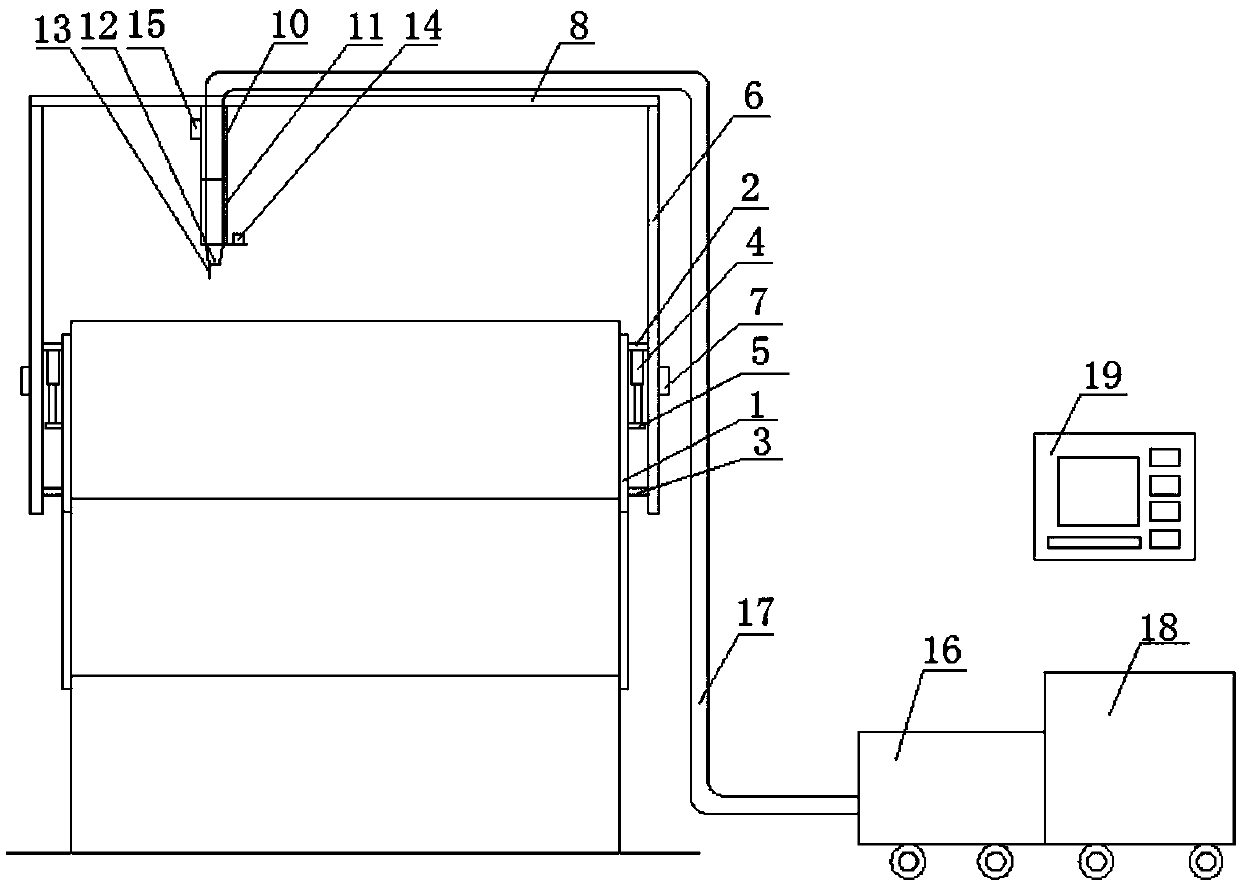

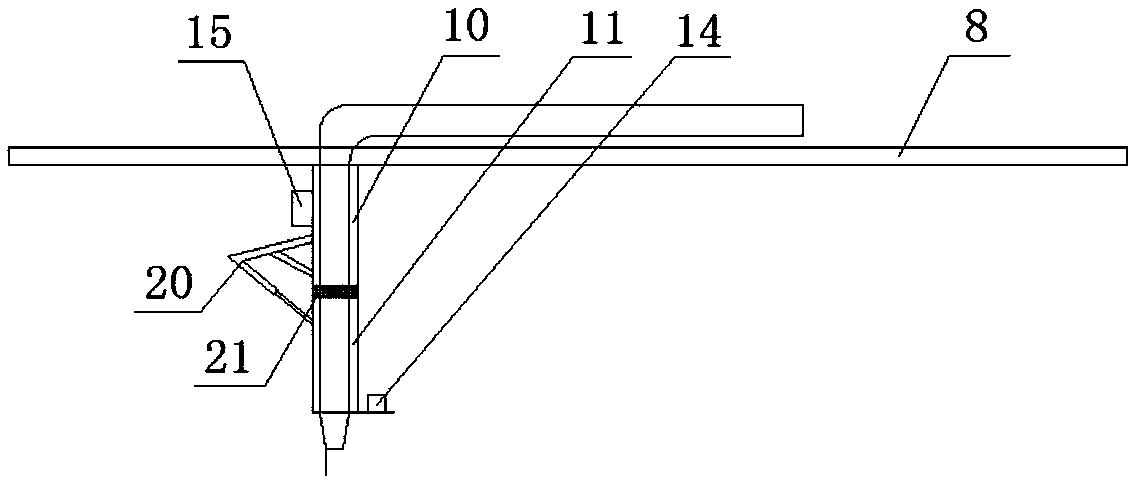

[0046] Such as figure 1 As shown, a self-elevating wall 3D printer for a high-rise building in this embodiment includes a lifting mechanism, a mobile support frame and a printing mechanism, wherein the mobile support frame is supported and installed on the top of the lifting mechanism, and the printing mechanism can be slidably installed on the mobile On the support frame, the above-mentioned lifting mechanism includes a guide rail 1, an upper holder 2, a lower holder 3, an electro-hydraulic pusher 4 and a column 6. The guide rail 1 is fixed on opposite sides of the building wall, and the upper holder 2, the lower holder The fixed base 5 of the fixer 3 and the electrohydraulic pusher 4 can be slidably installed on the guide rail 1, the lower end of the column 6 is fixedly connected with the upper fixer 2 and the lower fixer 3, and the mobile support frame is fixedly supported on the top of the column 6; The piston rod of the electric hydraulic pusher 4 is fixedly connected wit...

Embodiment 2

[0049] A self-elevating wall 3D printer for a high-rise building in this embodiment is basically the same in structure as Embodiment 1, the main difference is that the lifting mechanism of this embodiment is provided with a wireless control receiver I7, the wireless control receiver I7 is wirelessly connected with the control device 19, and the wireless control receiver I7 issues instructions through the wireless connection of the model digitization control device 19, thereby controlling the braking action of the brakes on the upper holder 2, the lower holder 3 and the fixed base 5.

Embodiment 3

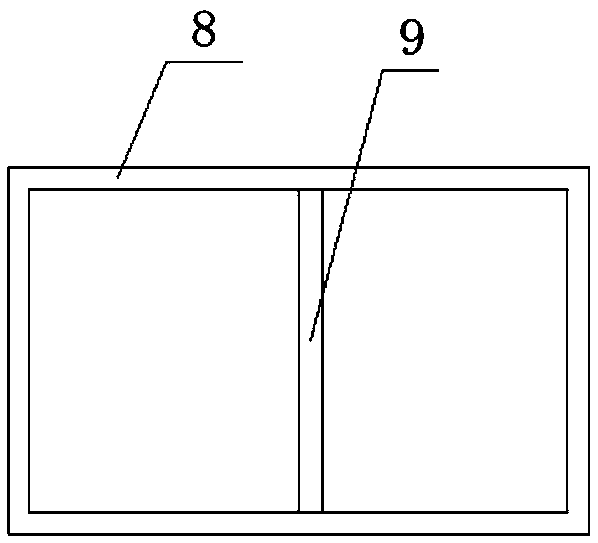

[0051] A self-elevating wall 3D printer for a high-rise building in this embodiment has a structure basically the same as that in Embodiment 2, and the difference mainly lies in: Figure 5 As shown, at least three groups of lifting mechanisms are provided on the opposite sides of the building wall, wherein the distance between adjacent columns 6 is 4-6 meters, and the upper fixers of the adjacent three groups of lifting mechanisms 2. The lower holder 3 and the fixed base 5 are distributed symmetrically up and down (staggered in height by 0.5-1 meters) to form a triangular structure. 3 and the fixed base 5 are fixedly connected. The number of lifting mechanisms on each side of the wall is determined by the width of the wall to be printed. The scattered arrangement of the columns 6 can also avoid the concentration of force. Since the bearing capacity of the wall after printing is relatively low, the external force will have a certain impact on the overall quality of the wall. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com