Skin feeling aqueous polyurethane coating and preparation method thereof

A water-based polyurethane and coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as the incompetence of the laminating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

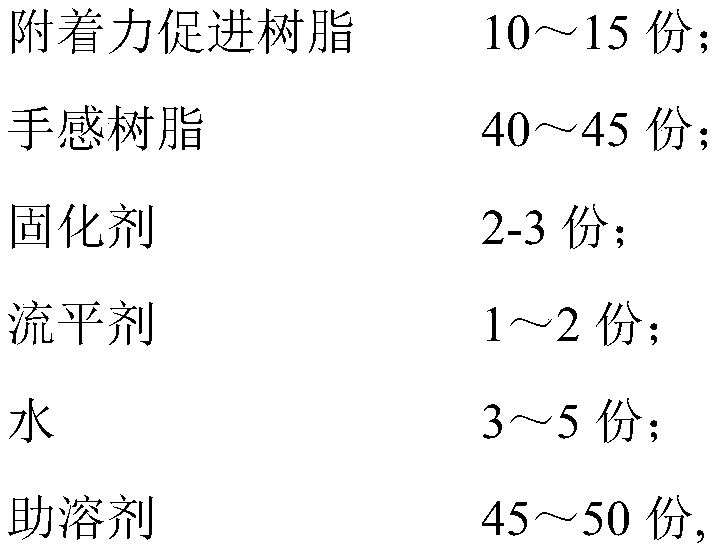

[0078] (1) A waterborne polyurethane coating, said coating is made up of the component of following mass parts:

[0079]

[0080] (2) Preparation of waterborne polyurethane coating:

[0081] First mix the above-mentioned aziridine, byk333, water and ethanol evenly, then add RICC-622 and RICC-90, stir at room temperature at 800 rpm for half an hour to prepare water-based polyurethane coatings.

[0082] (3) Effect evaluation of waterborne polyurethane coatings:

[0083] Apply the water-based polyurethane coating prepared in step (2) evenly on the surface of the PVC substrate by roller coating, dry it in a drying tunnel at 60°C and wind it up, and then bake it with equipment at 60°C for 5 hours to crosslink the coating internally Complete, the skin-sensitive film can be prepared, and the evaluation results are shown in Table 1.

Embodiment 2

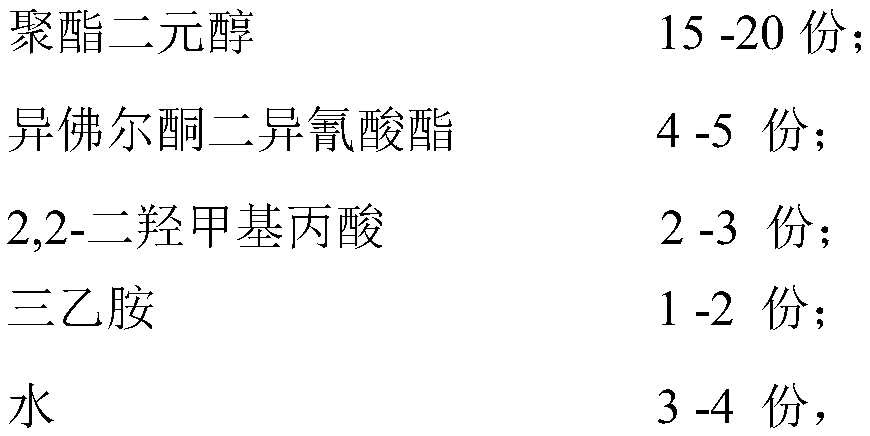

[0085] (1) A waterborne polyurethane coating, said coating is made up of the component of following mass parts:

[0086]

[0087]

[0088] (2) Preparation of waterborne polyurethane coating:

[0089] First mix the above-mentioned aziridine, byk333, water and ethanol evenly, then add RICC-622 and RICC-90, stir at room temperature at 800 rpm for half an hour to prepare water-based polyurethane coatings.

[0090] (3) Effect evaluation of waterborne polyurethane coatings:

[0091] Apply the water-based polyurethane coating prepared in step (2) evenly on the surface of the PVC substrate by roller coating, dry it in a drying tunnel at 60°C and wind it up, and then bake it with equipment at 60°C for 5 hours to crosslink the coating internally Complete, the skin-sensitive film can be prepared, and the evaluation results are shown in Table 1.

Embodiment 3

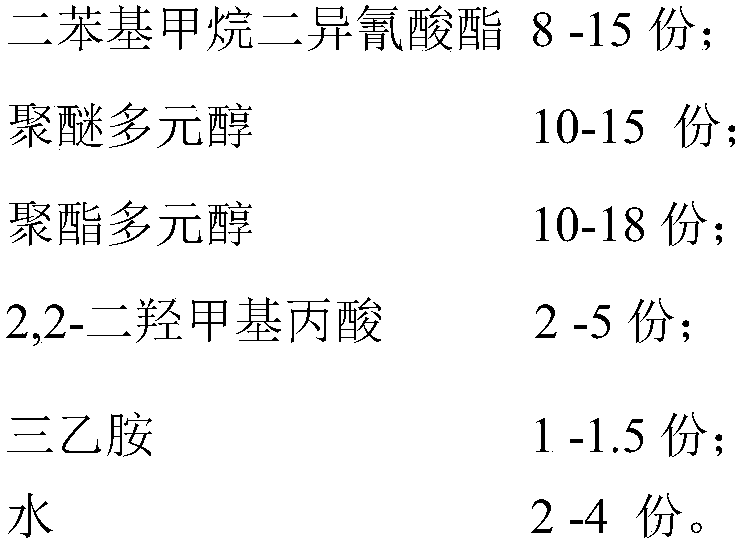

[0093] (1) A waterborne polyurethane coating, said coating is made up of the component of following mass parts:

[0094]

[0095] (2) Preparation of waterborne polyurethane coating:

[0096] First mix the above-mentioned aziridine, silok8333, water and isopropanol in parts by mass evenly, then add RICC-622 and RICC-90, and stir at room temperature at 800 rpm for half an hour to prepare a water-based polyurethane coating.

[0097] (3) Effect evaluation of waterborne polyurethane coatings:

[0098] Apply the water-based polyurethane coating prepared in step (2) evenly on the surface of the PVC substrate by roller coating, dry it in a drying tunnel at 60°C and wind it up, and then bake it with equipment at 60°C for 5 hours to crosslink the coating internally Complete, the skin-sensitive film can be prepared, and the evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com