Woof doubling detecting device and using method

A technology of thread detection and weft thread, which is applied in the field of weft thread doubling detection device, can solve problems such as easy missed detection, weft thread is easy to break, and there is no balanced yarn tension, so as to reduce the adsorption of impurities, improve the effect of doubling threads, and reduce the risk of breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

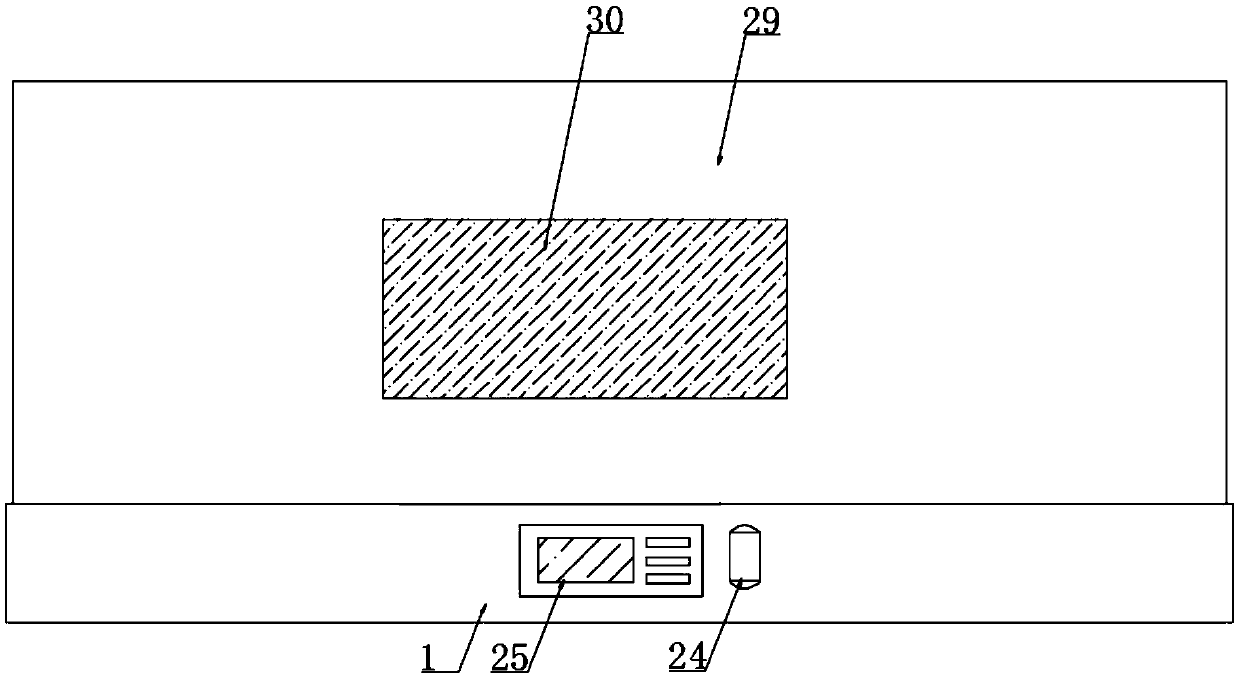

[0033] according to Figure 1-6 A weft parallel detection device shown includes a base 1, a pay-off wheel 2 is rotatably connected to one end of the top of the base 1, and a doubling machine 3 is fixedly connected to the other end of the top of the base 1, and the pay-off wheel 2 One side is fixedly connected with a cylinder 4, the top of the cylinder 4 is provided with a harness 5, one side of the doubling machine 3 is fixedly connected with a bracket, the top of the bracket is provided with a transmission roller 6, and one end of the transmission roller 6 is provided with There is a motor 7, a detection frame 8 is arranged between the cylinder 4 and the support, the top of the detection frame 8 is fixedly connected with a horizontal frame 9, and the end of the horizontal frame 9 away from the detection frame 8 is provided with a lead groove 10, the A plurality of guide rollers 11 distributed in parallel are arranged in the lead wire groove 10, and chute 12 is provided on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com