Device for detecting signals of rocket power filling system

A filling system and signal technology, used in transportation and packaging, ground equipment for space navigation, space navigation equipment, etc., can solve the problems of difficult centralized management of the meter head, high cost, and inability to grasp the data of the front-end power filling system in real time. , to achieve the effect of reducing the design process and time cycle, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

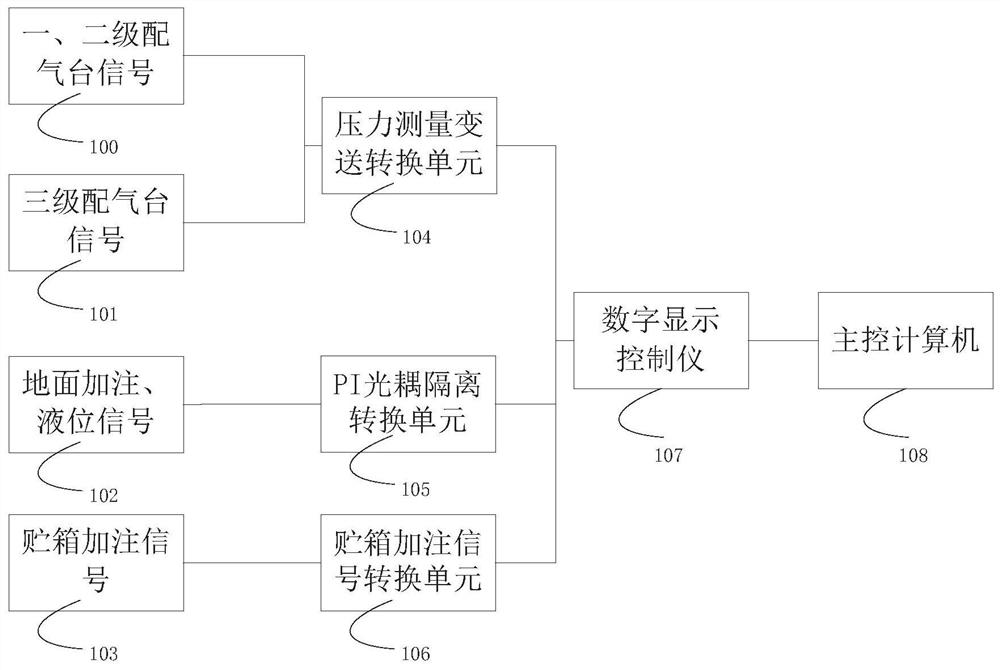

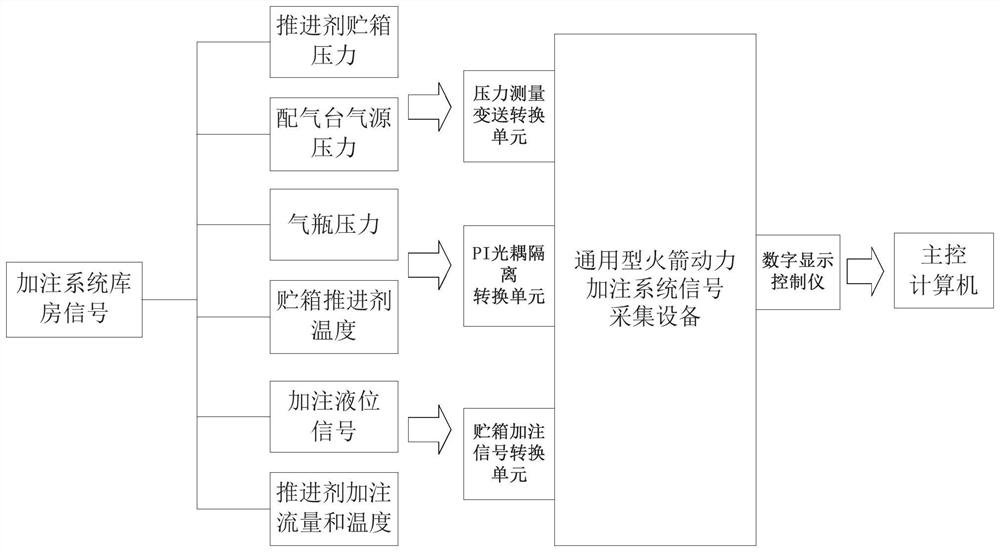

[0021] Such as figure 1 with 2 As shown, the present invention provides a kind of device for detecting rocket power filling system signal, comprising:

[0022] A pressure measurement transmission conversion unit 104, one side of the pressure measurement transmission conversion unit receives the gas source pressure signals given by the first, second and third gas distribution platforms of the filling warehouse;

[0023] PI optocoupler isolation conversion unit 105;

[0024] Tank filling signal conversion unit 106;

[0025] The digital display controller 107 and the main control computer 108 connected with the digital display controller 107, the digital display controller 107 and the main control computer 108 are respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com