Compound colored sheet and preparation method and application thereof

A sheet and color technology, applied in the field of composite color sheet and its preparation, can solve the problems of large loss, reduced loss, difficult chromatic aberration control, etc., and achieve the effects of reduced loss, small chroma and high peel strength in the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

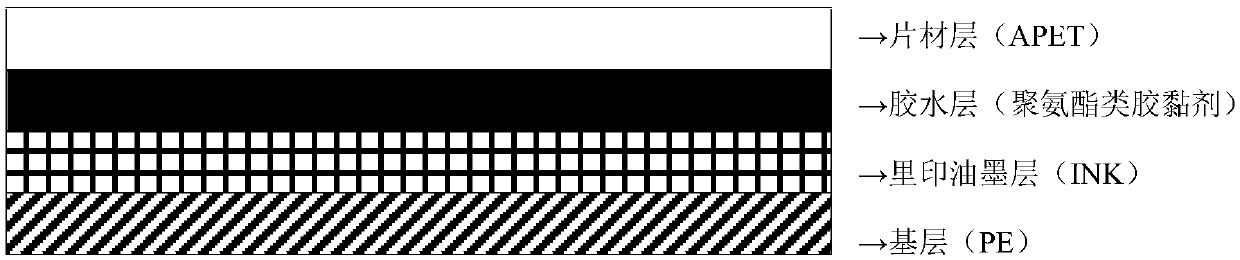

[0029] The preparation of a color sheet with a structure of APET / glue / INK / PE and a thickness of 300 μm includes the following steps:

[0030] 1) Select a PE film with a surface tension value of 38-42 dynes, and install a blank printed composite substrate PE film on the unwinding device;

[0031] 2) Select 10 parts of polyurethane printing ink (purchased from Suzhou Zhongya, green ink UMT99-R500 in embodiment 1, red ink UMT99-R105 in embodiment 2), and add 0.25 parts of polyurethane ink curing agent (purchased from Suzhou Zhongya Asia, grade CVL#12), put the two into the ink tank and mix them, and use the ink stirring stick to stir for 5 minutes;

[0032] 3) carry out back printing to the PE film by gravure printing or flexo printing with the mixed back printing ink prepared in step 2;

[0033] 4) Rewind according to the number of winding meters. After printing, place the printed PE printing film in an environment of 30-50°C and humidity 55-75%RH, and mature for more than 12 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com