Cooling-type gas-liquid separator

A gas-liquid separator, cooling technology, applied in the direction of the cyclone axial reversal device, cyclone device and other directions, can solve the problem of affecting the normal operation of the fuel cell system, not suitable for the separation of anode products, etc., to solve the problem. Secondary condensation problem, overcoming incomplete separation, small flow pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The application will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the application and implement it, but the examples given are not intended to limit the application.

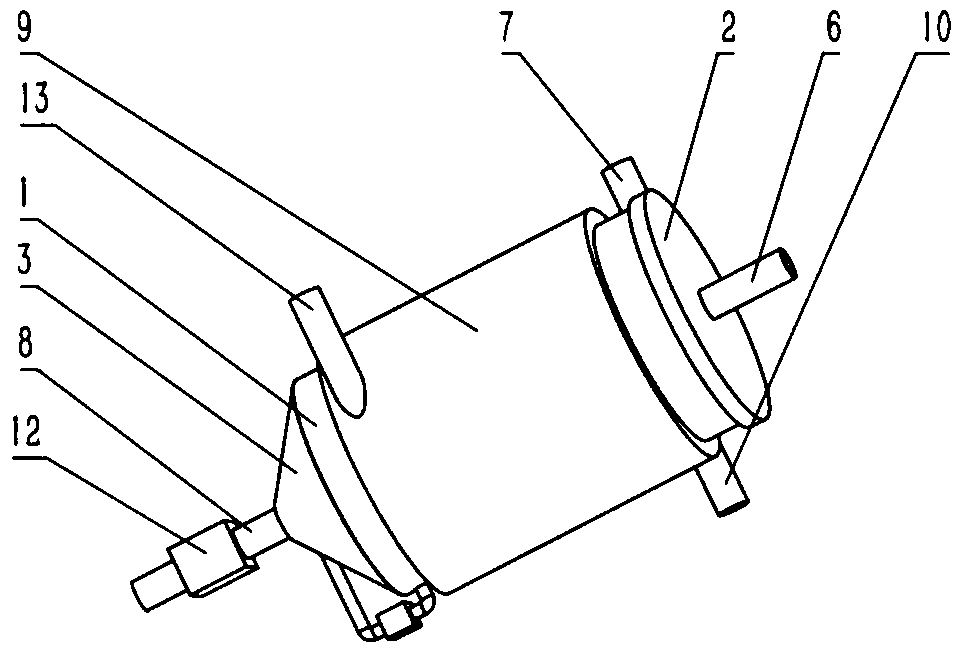

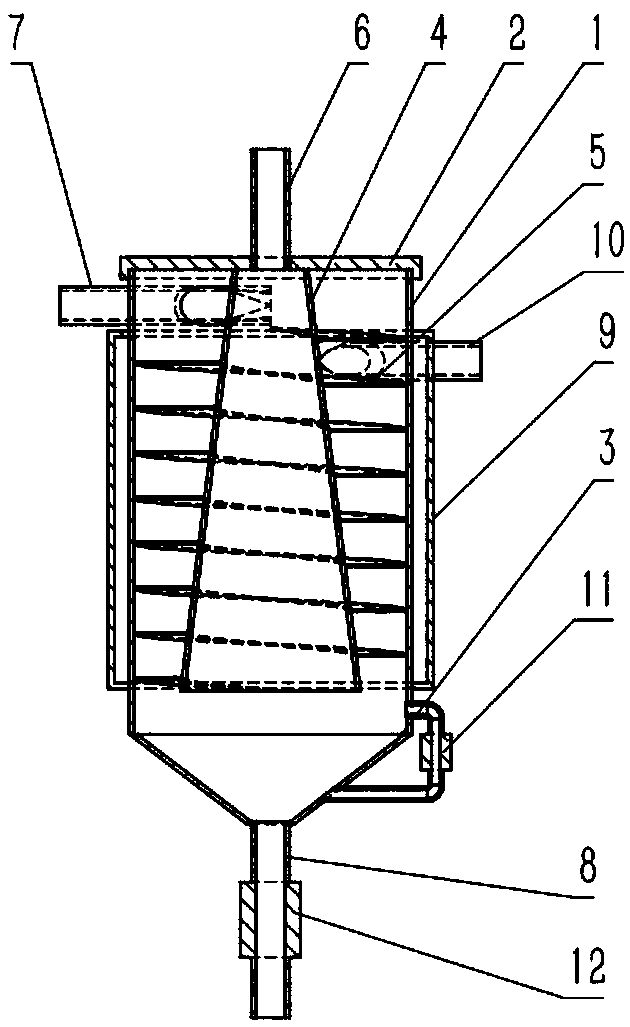

[0018] As shown in the figure, the application provides a cooling type gas-liquid separator, the separator includes an inner cylinder 1, an air guiding cylinder 4 arranged in the inner cylinder 1, and the inner cylinder The upper end of 1 is provided with a cylinder cover 2, the upper end of the air guide cylinder 4 is sealed and connected with the lower surface of the cylinder cover 2, the lower end of the air guide cylinder 4 has an opening, and the outer wall of the air guide cylinder 4 is set There is at least one helical piece 5, the inner edge of the helical piece 5 is fixed on the outer wall of the air guiding cylinder 4, and the outer edge of the helical piece 5 is sealingly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com