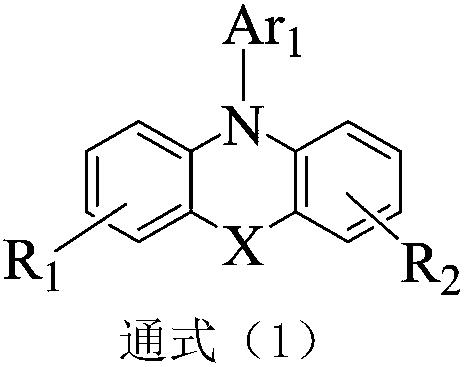

Dibenzo-hexatomic ring-cored compound and application thereof to organic electroluminescent device

A compound and six-membered ring technology, which can be used in electric solid devices, electrical components, luminescent materials, etc., can solve very different problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Embodiment 1: the synthesis of intermediate BI and intermediate BII:

[0091]

[0092] 1) dissolving raw material O and raw material P with toluene, wherein, the molar ratio of raw material O and raw material P is 1:(1.0~1.5);

[0093] 2) Add Pd to the reaction system in 1) 2(dba) 3 , tri-tert-butylphosphine, sodium tert-butoxide; the Pd 2 (dba) 3 The molar ratio with raw material O is (0.005~0.01):1, the molar ratio of described tri-tert-butylphosphine and raw material O is (0.005~0.02):1, and the molar ratio of described sodium tert-butoxide and raw material O is (1.5~3.0):1;

[0094] 3) Under the protection of an inert gas, react the above-mentioned mixed solution at a temperature of 95-110° C. for 10-24 hours, naturally cool to room temperature, and filter the reaction solution. The filtrate is rotary evaporated to no solvent, and passed through a neutral silica gel column. Obtain intermediate B1;

[0095] Take the synthesis of intermediate B1 as an example...

Embodiment 2

[0112] Embodiment 2: the synthesis of compound 3:

[0113]

[0114] In a 250ml three-neck flask, under the protection of nitrogen, add 0.01mol raw material 1, 0.012mol intermediate B2, 150ml toluene and stir to mix, then add 0.02mol sodium carbonate, 1×10 -4 molPd(PPh 3 ) 4 , heated to 105 ° C, reflux reaction for 24 hours, sampling point plate, showing no bromide remaining, the reaction is complete; naturally cooled to room temperature, filtered, the filtrate was subjected to vacuum rotary evaporation (-0.09MPa, 85 ° C), passed through neutral silica gel Column, obtain target product, HPLC purity 99.0%, yield 75.3%; Elemental analysis structure (molecular formula C 54 h 34 N 2 o 3 ): Theoretical value: C, 85.47; H, 4.52; N, 3.69; O, 6.32; Test value: C, 85.43; H, 4.55; N, 3.65; ESI-MS(m / z)(M + ): The theoretical value is 758.88, and the measured value is 758.75.

Embodiment 3

[0115] Embodiment 3: the synthesis of compound 8:

[0116]

[0117] In a 250ml three-neck flask, under the protection of nitrogen, add 0.01mol raw material 2, 0.012mol intermediate B3, 150ml toluene and stir to mix, then add 0.03mol sodium tert-butoxide, 5×10 -5 molPd 2 (dba) 3 , 5×10 -5 mol of tri-tert-butylphosphine, heated to 105°C, refluxed for 24 hours, sampling plate, showed no remaining bromide, the reaction was complete; naturally cooled to room temperature, filtered, and the filtrate was rotary evaporated under reduced pressure (-0.09MPa, 85°C ), through neutral silica gel column, obtain target product, HPLC purity 98.5%, yield 67.8%; Elemental analysis structure (molecular formula C 54 h 44 N 2 ): Theoretical value: C, 89.96; H, 6.15; N, 3.89; Tested value: C, 89.94; H, 6.15; N, 3.91. ESI-MS(m / z)(M + ): The theoretical value is 720.96, and the measured value is 720.85.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com