Concrete preparation method capable of promoting quick development of strength through pre-aging

A concrete and rapid technology, applied in the direction of clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc., can solve the problems that steam curing does not conform to the direction of social development, increase the cost of concrete steam, and avoid quality defects and performance degradation , shorten the demoulding time and avoid the effect of steam curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

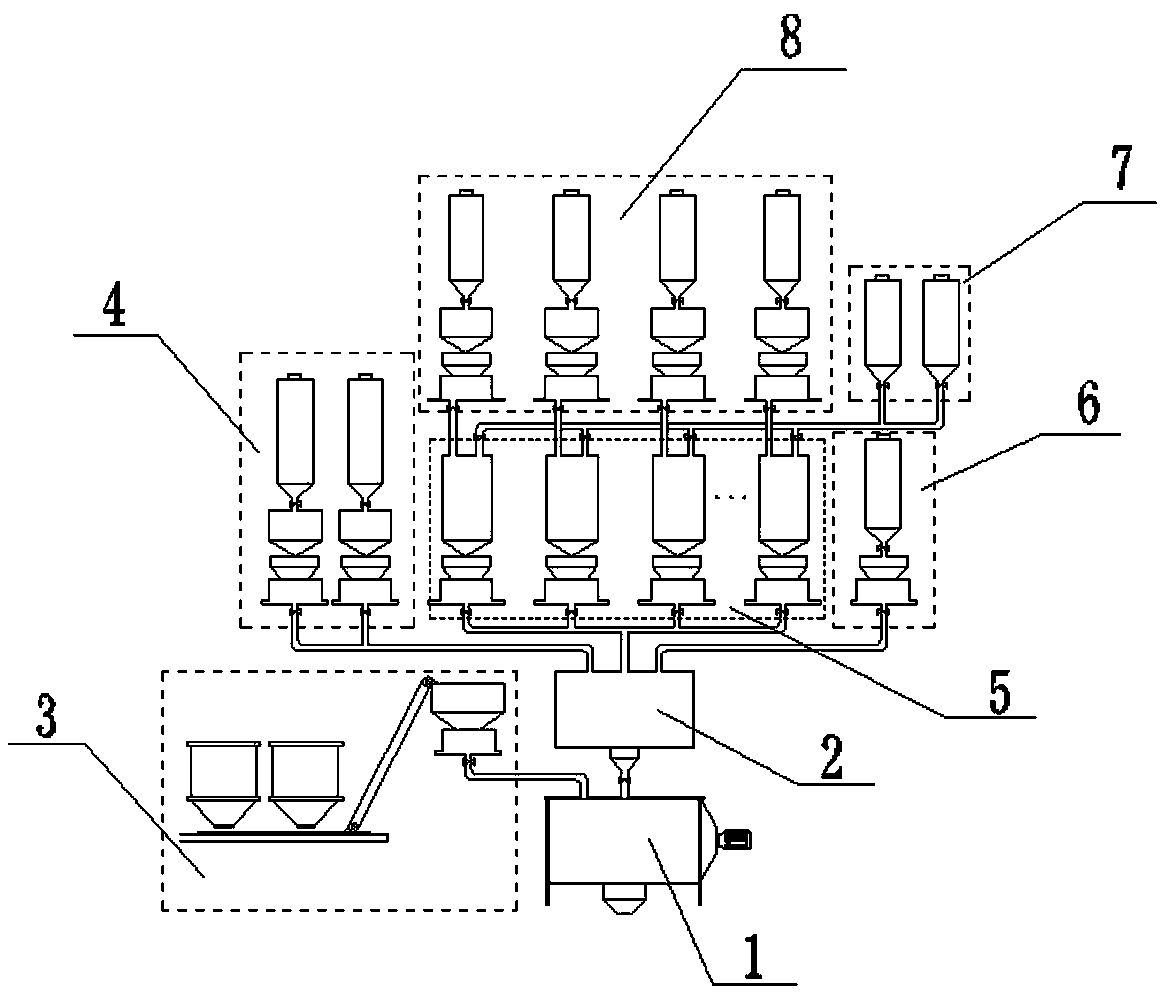

Image

Examples

Embodiment 1

[0031] A method for preparing concrete that promotes the rapid development of strength by pre-aging, and the preparation process includes construction mix ratio design, preparation and aging of cement paste, and concrete preparation; the specific method process is as follows:

[0032] Part 1: Construction mix design

[0033] The concrete construction mix ratio is designed according to the strength grade and workability requirements of the prefabricated building components; the specific concrete construction mix ratio includes: 185 parts of water, 325 parts of cement (P.O.42.5 cement), 662 parts of sand (sand is medium sand, fineness The modulus is 2.3~3.0), 1228 parts of stones (the stone is crushed stone with a particle size of 5~40mm.) and 5 parts of polycarboxylate high-performance water reducer, parts by weight;

[0034] (1) Determination of the initial setting time of the cement paste: prepare the cement paste according to the water-cement ratio in the above-mentioned con...

Embodiment 2

[0045] Concrete according to the method in Example 1, the difference is that the concrete construction mix ratio is: parts by weight are: 185 parts of water, 370 parts of cement (P.O.42.5 cement), 609 parts of sand (sand is medium sand, fine modulus of 2.3 to 3.0), 1236 parts of stones (the stone is crushed stone with a particle size of 5 to 40mm.) and 6 parts of polycarboxylate high-performance water reducer.

[0046] Determination of initial setting time of cement paste, denoted as T 1 =9h;

[0047] The daily production time of concrete is denoted as T 2 = 12h, then the number of cement paste preparations per day n = T 2 / T 1 , where n is an integer, n=2.

Embodiment 3

[0049] Concrete according to the method in Example 1, the difference is that the concrete construction mix ratio is: parts by weight are: 185 parts of water, 420 parts of cement (cement is P.O.42.5 cement), 572 parts of sand (sand is medium sand) , fineness modulus is 2.3 ~ 3.0), 1273 parts of stones (the stone is crushed stone, particle size is 5 ~ 40mm.) and 7 parts of polycarboxylate high-performance water reducer.

[0050] Determination of initial setting time of cement paste, denoted as T 1 =7h;

[0051] The daily production time of concrete is denoted as T 2 = 12h, then the number of cement paste preparations per day n = T 2 / T 1 , where n is an integer, n=2.

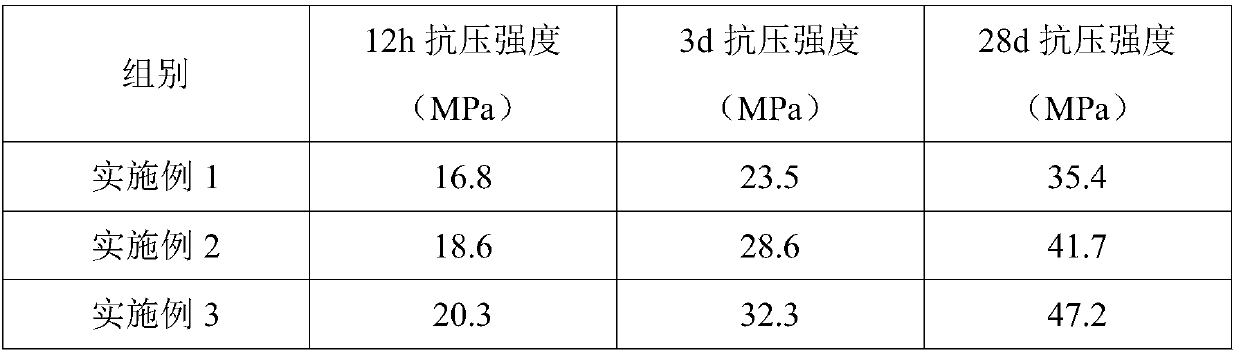

[0052] For the proportioning of Example 1, Example 2 and Example 3, the strength rapid development concrete prepared according to the method of the example was tested for compressive strength, and the test results are shown in the table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com