Semi-matt lead-free glass powder for automobile backstop glass and preparation method of glass powder

A light lead-free glass and glass shielding technology, applied in the field of glass powder, can solve the problems of glaze reflection, low strength, and non-matt surface, etc., and achieve the effect of good shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

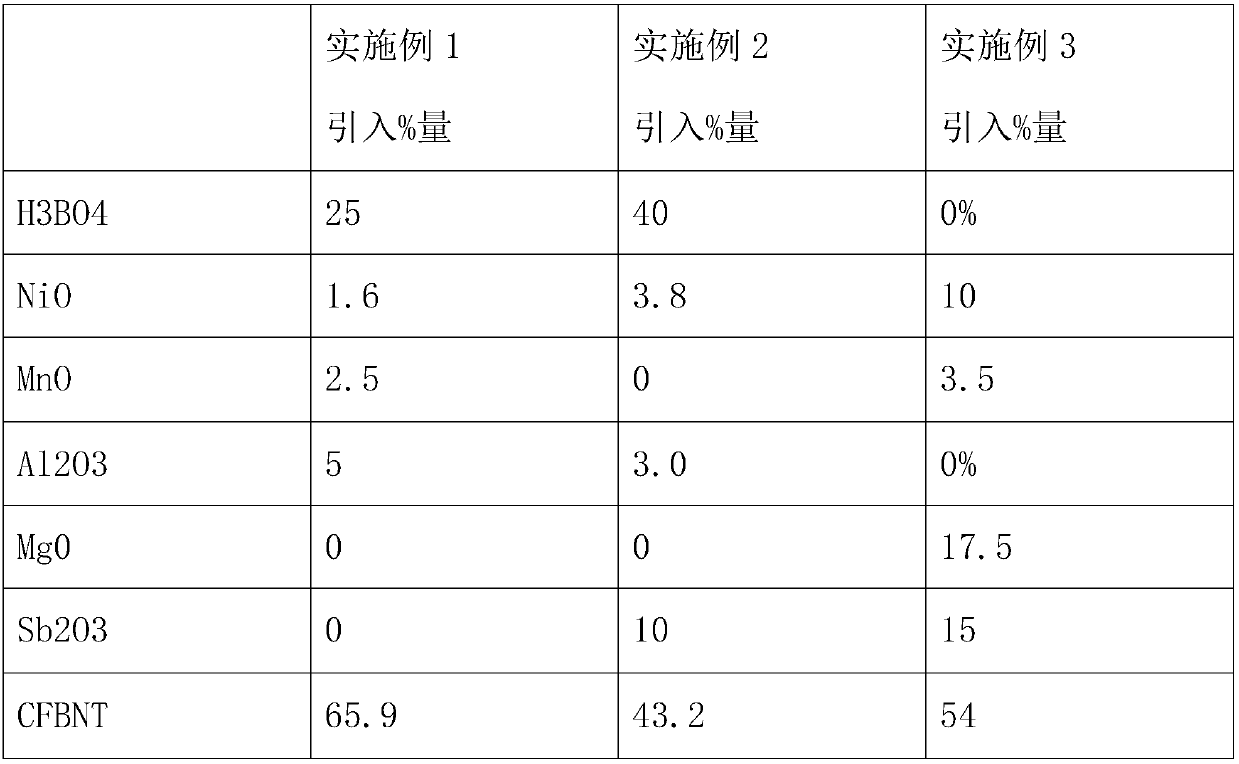

Examples

Embodiment 1

[0033] step 1:

[0034] First, the HNMMAS material is weighed according to the proportion and then mixed for use. The mixed material is melted at a high temperature of 1000°C, and it is discharged and quickly poured into pure water to form a quenched granular material. ;

[0035] Step 2;

[0036] The CFBNT material is weighed according to the proportion and mixed for use;

[0037] Step 3;

[0038] Melt the CFBNT mixture in step 2 at a high temperature of 1000°C, and pour it into pure water quickly after discharging to form a quenched granular material.

[0039] Step 4;

[0040] The granules obtained in step 3 are dried and pulverized to below 2um;

[0041] Step 5;

[0042] The granular material in the step 4 is mixed with the HNMMAS mixture in the step 1 for subsequent use;

[0043] Step 6;

[0044] Carry out secondary mixing with the mixture in step 5 after the material that does not participate in proportioning is weighed in proportion;

[0045] Step 7;

[0046] Th...

Embodiment 2

[0052] step 1:

[0053] Firstly, the HNMMAS material in it is weighed according to the proportion and then mixed for use. The mixed material is melted at a high temperature of 1250 ° C, and it is discharged and quickly poured into pure water to form a quenched granular material. ;

[0054] Step 2;

[0055] Weigh the CFBNT material according to the proportion and mix it for use;

[0056] Step 3;

[0057] Melt the CFBNT mixture in step 2 at a high temperature of 1250°C, and pour it into pure water quickly after discharging to form a quenched granular material.

[0058] Step 4;

[0059] Dry the granular material obtained in step 3, and crush it to below 2u;

[0060] Step 5;

[0061] The granular material in the step 4 is mixed with the compound in the step 1 for subsequent use;

[0062] Step 6;

[0063] Carry out secondary mixing with the mixture in step 5 after the material that does not participate in proportioning is weighed in proportion;

[0064] Step 7;

[0065] T...

Embodiment 3

[0071] step 1:

[0072] Firstly, the HNMMAS material in it is weighed according to the proportion and then mixed for use. The mixed material is melted at a high temperature of 1100 ℃, and it is discharged and quickly poured into pure water to form a quenched granular material. ;

[0073] Step 2;

[0074] Weigh the CFBNT material according to the proportion and mix it for use;

[0075] Step 3;

[0076] Melt the CFBNT mixture in step 2 at a high temperature of 1100°C, and pour it into pure water quickly after discharging to form a quenched granular material.

[0077] Step 4;

[0078] The granules obtained in step 3 are dried and pulverized to below 2um;

[0079] Step 5;

[0080] The granular material in the step 4 is mixed with the compound in the step 1 for subsequent use;

[0081] Step 6;

[0082]Carry out secondary mixing with the mixture in step 5 after the material that does not participate in proportioning is weighed in proportion;

[0083] Step 7;

[0084] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com