Intelligent loading system used for high-altitude building garbage clearance and application method

A technology for construction waste and garbage, which is applied in the direction of garbage cans, garbage collection, garbage storage, etc., can solve the problems of high labor cost, low efficiency, environmental pollution and other problems of garbage removal and transportation, and achieve manpower saving, convenient and fast operation, and easy cleaning and transportation. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

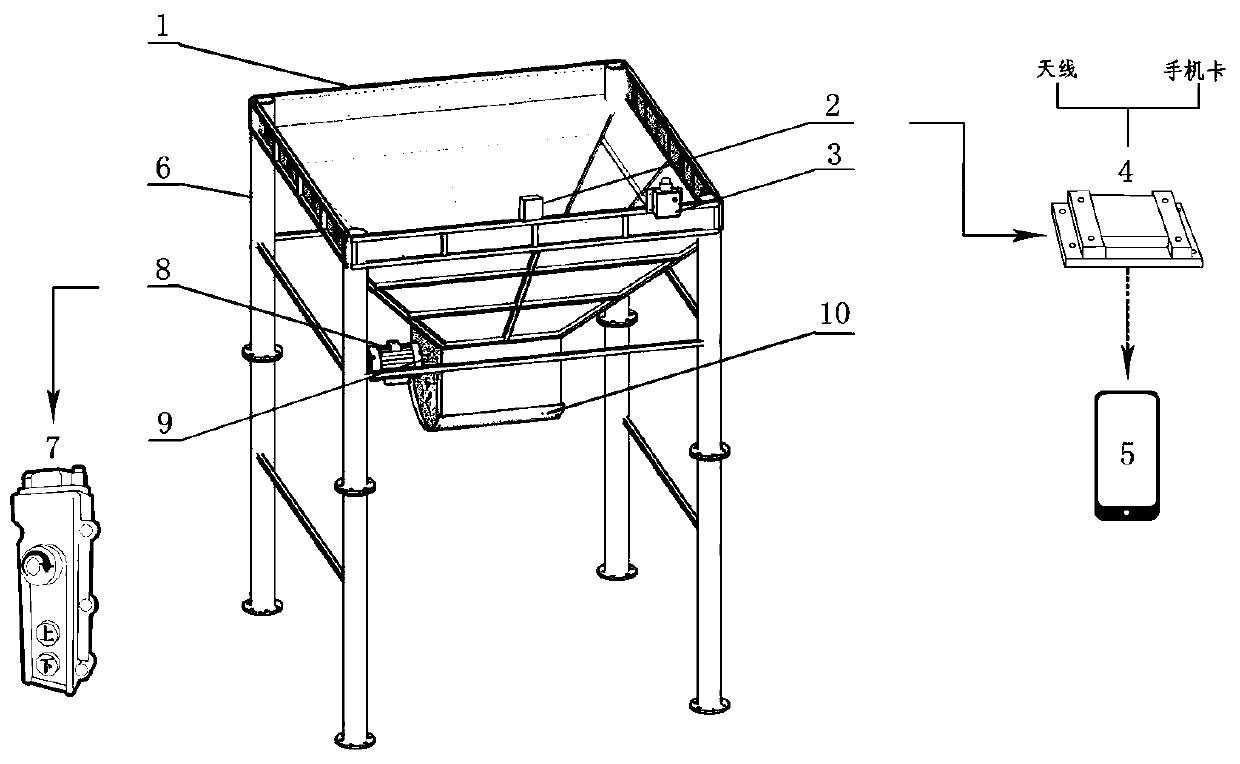

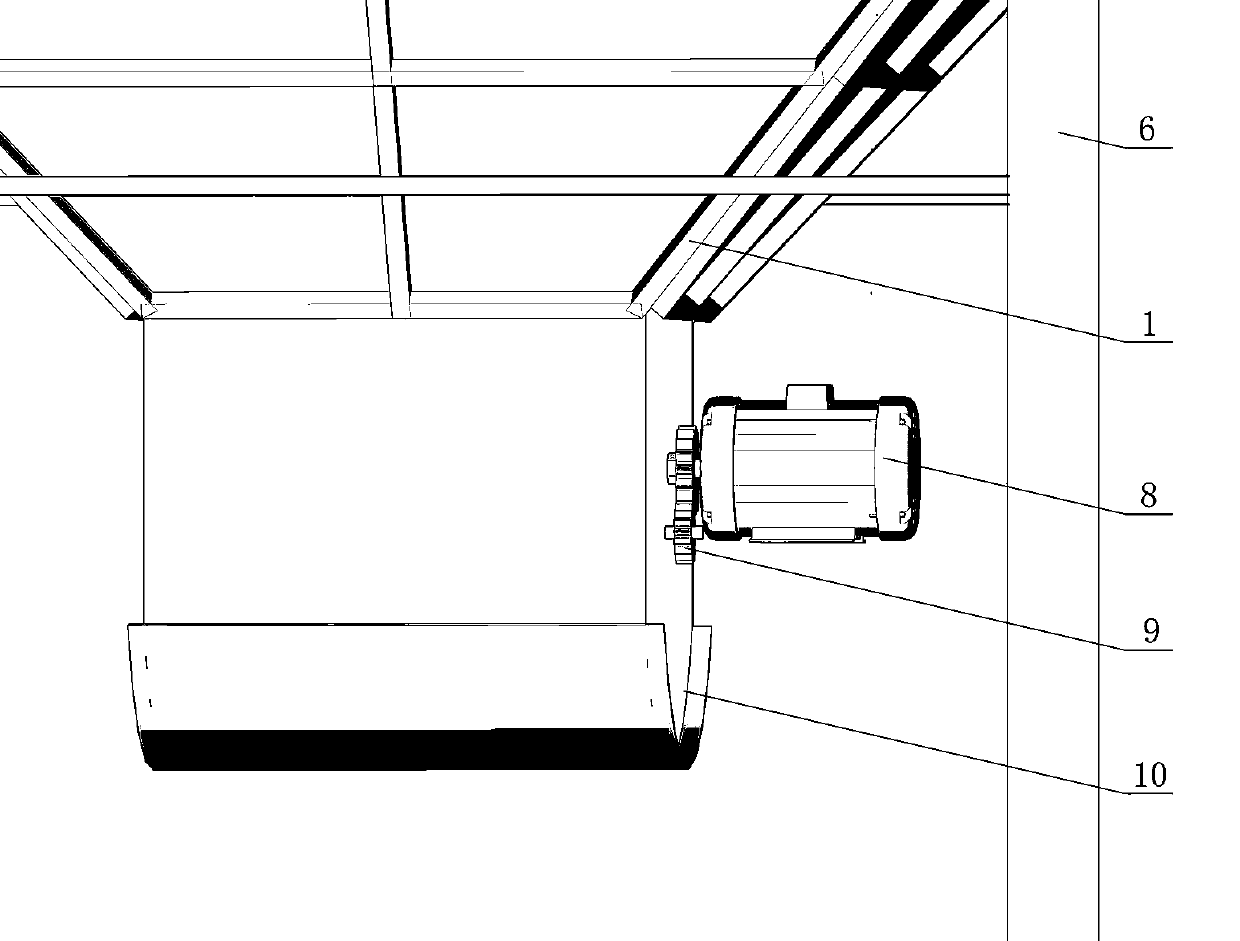

[0020] Such as figure 1 Shown is a schematic diagram of the overall structure of an intelligent loading system for high-altitude construction waste removal and transportation of the present invention, including high-altitude garbage storage and transportation box 1, photoelectric sensor 2, GSM remote controller 4, mobile phone terminal 5, box column 6. The controller 7, the motor 8, the gear mechanism 9 and the discharge port 10. The high-altitude garbage storage and transportation box 1 is erected in the high-altitude position of the construction site through the box column 6 with a discharge port 10 at the bottom and installed on the side There are motor 8.

[0021] The motor 8 can open and close the discharge port 10 by driving the gear mechanism 9. The photoelectric sensor 2 is arranged on the upper part of the high-altitude garbage storage and transportation box 1 to sense the height of the internal garbage. The GSM remote control The device 4 can realize communication and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com