Novel electric control system of suspension conveying system for high-temperature materials

An electrical control system and high-temperature material technology, applied in furnace control devices, charge control, lighting and heating equipment, etc., can solve the problems of affecting the time of reducing slag out of the furnace, burn on-site operators, etc., and achieve labor-saving and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

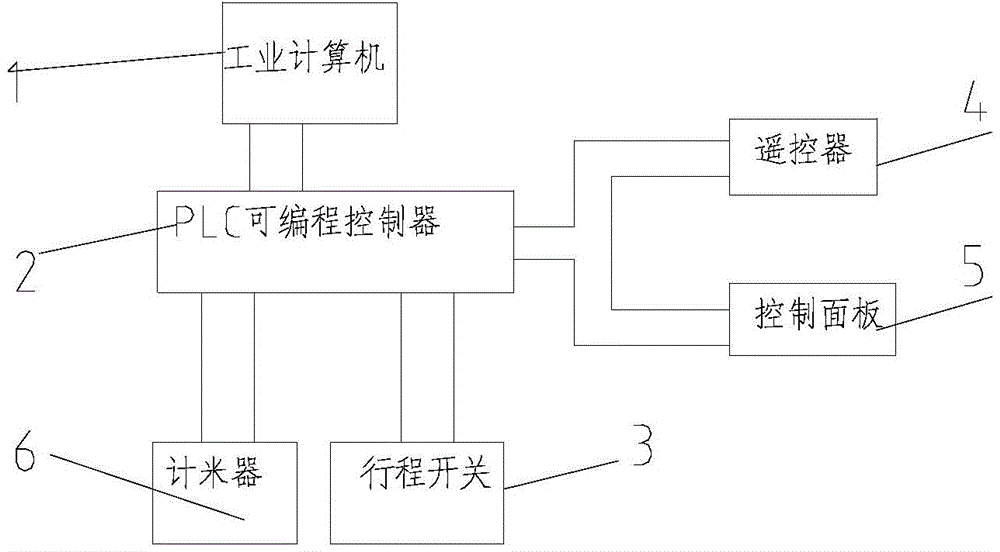

[0011] Example 1 Composition of the electrical control system of a new suspension conveying system for high-temperature materials and the functions of each component:

[0012] The system consists of industrial computer 1, PLC programmable controller 2, travel switch 3, remote controller 4, control panel 5, and meter counter 6. The electrical control system of the control system is an automatic operation system controlled by a PLC programmable controller 2 . The travel switch 3 is used to control the lifting, advancing and unloading actions of the slag box. The remote controller 4 can control the actions of the system within a range of 100 meters. The control panel 5 performs action control at the work site.

Embodiment 2

[0013] Example 2 The working principle of the electrical control system of a new type of suspension conveying system for high-temperature materials:

[0014] When the spreader moves to the position where the travel switch 3 is installed at the position where the reduction slag box needs to be hoisted, advanced and unloaded, after touching the travel switch 3, it will carry out suspension, lifting, forward and unloading according to the action set by the PLC programmable controller 2 program action. The meter counter 6 is used to calculate the running distance of the reduced slag box 8 at each tank mouth, and can modify the travel distance data according to the storage situation of the reduced slag tank 9, so that the reduced slag box 8 reaches the position to be unloaded .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com