Novel suspended conveying system for high-temperature materials

A high-temperature material and conveying system technology, which is applied in the field of conveying systems, can solve problems such as burns to on-site operators and affect the time for reducing the slag to be released from the furnace, and achieve the effects of conveying realization, stable operation, and mechanized conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

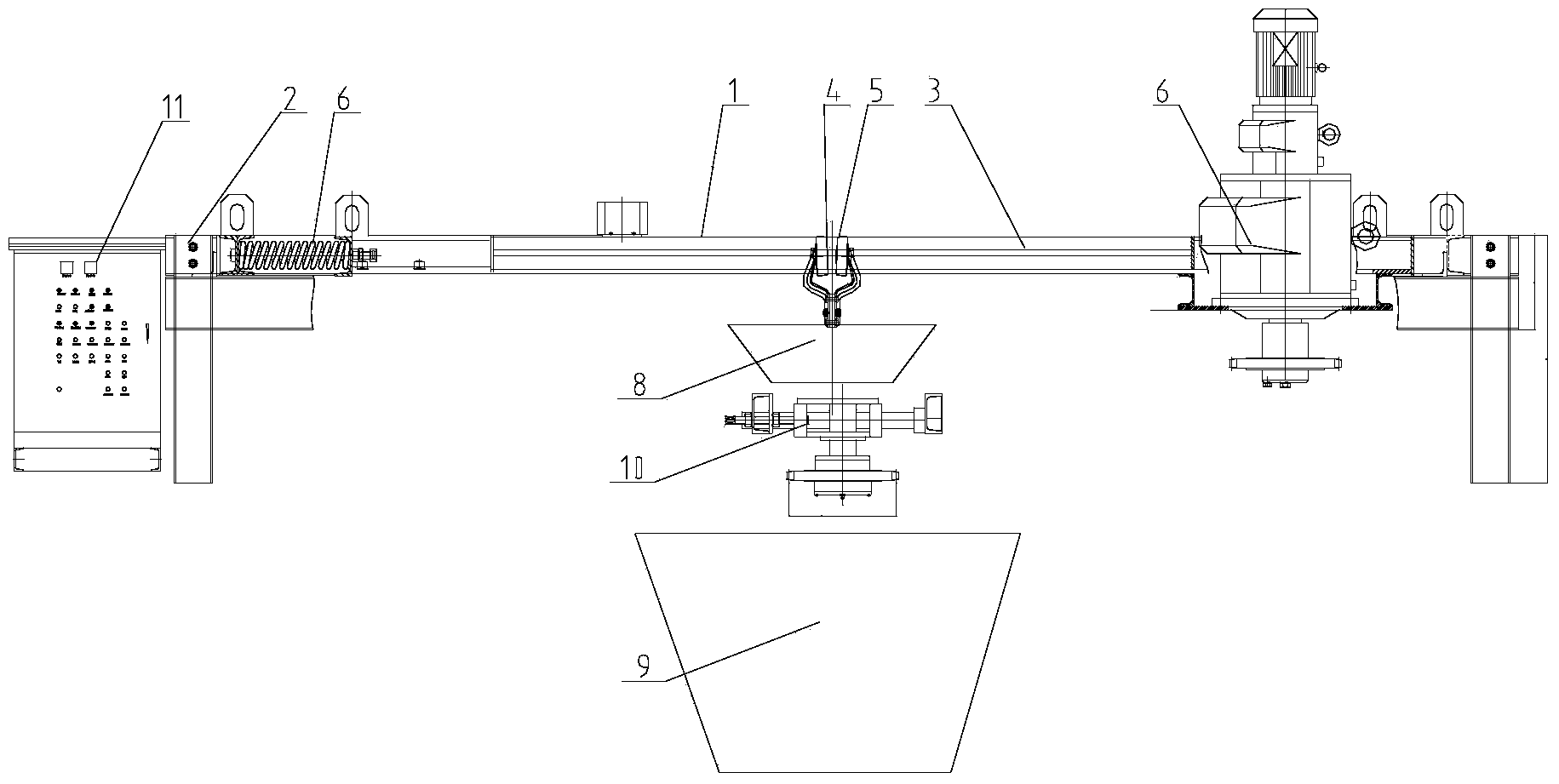

[0011] Example 1 Composition of a new suspension conveying system for high-temperature materials and the functions of its components:

[0012] The system includes overhead circular track 1, overhead circular track support 2, traction chain 3, carriage 4, spreader 5, driving device 6, tensioning device 7, reduced slag box 8, reduced slag storage tank 9, slag box dumping device 10. It consists of an electrical control system 11. The spreader 5 runs on the overhead circular track 1, and the system runs under the control of the electrical automatic control system 11. The overhead ring track support 2 is installed on the ground or hangs. The tensioning device 7 is used to adjust the tightness of the traction chain 3 . Reduction slag box 8 is steel structure, has the suspension hook that cooperates with suspender 5. The reducing slag storage tank 9 is a cement structure storage tank or a steel structure storage tank for reducing slag storage. The slag box dumping device 10 is a...

Embodiment 2

[0013] Example 2 The working process of a new type of suspension conveying system for high-temperature materials:

[0014] After the high-temperature reduction slag from the reduction furnace falls into the reduction slag box 8, the on-site operators can control the operation of the spreader 5 through panel operation or remote control. The spreader 5 is pulled by the traction chain 3 and driven by the driving device 6 along the Rack 4 runs. After the lifting tool 5 lifts the reduced slag box 8 to the position where the reduced slag can be unloaded and dumped in the reduced slag storage tank 9, the high temperature reduced slag in the reduced slag box 8 is poured into the reducing slag under the action control of the slag box dumping device 10. In the slag storage tank 9, then reset the reduced slag box 8, the spreader 5 lifts the reduced slag box 8 back to the original initial position, and drops the reduced slag box 8 at the designated position to complete the reduced slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com