An engine packing box

A packaging box and engine technology, applied in the field of packaging, can solve problems such as fixing the engine, evenly distributing the weight of the engine to the cardboard and other objects, and the quality of the engine engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

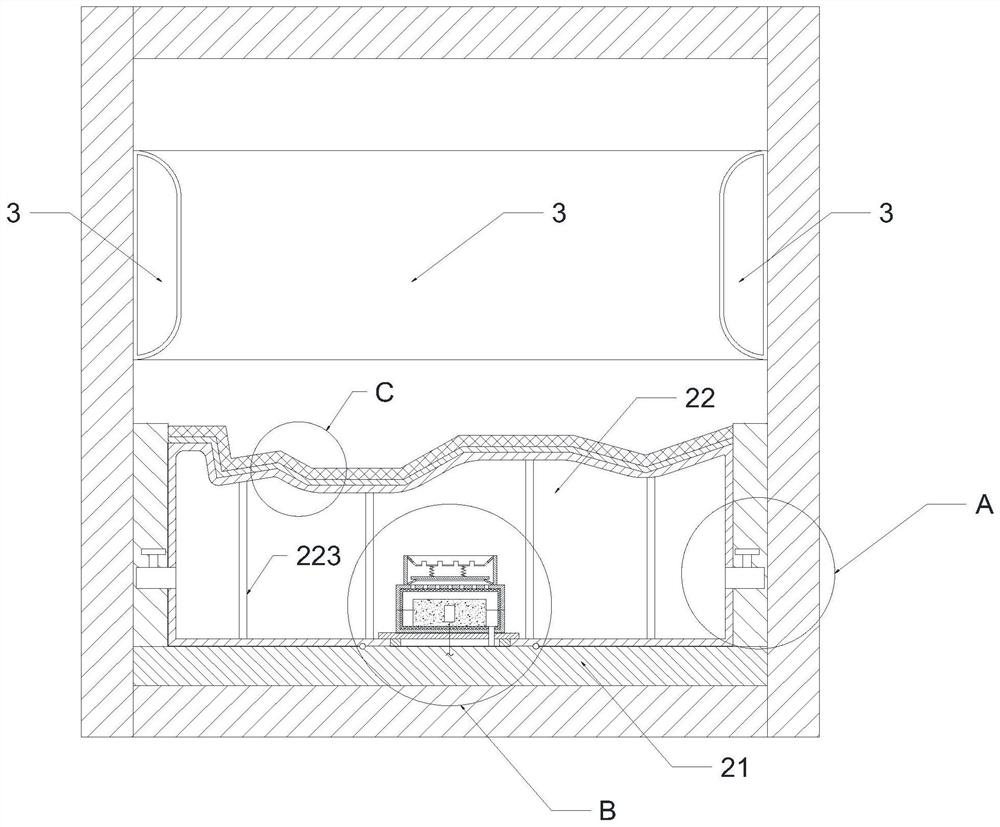

[0037] Example: such as Figure 1 to Figure 5 Shown:

[0038] The engine packaging box includes a box frame 1, a base, and a cladding unit 3;

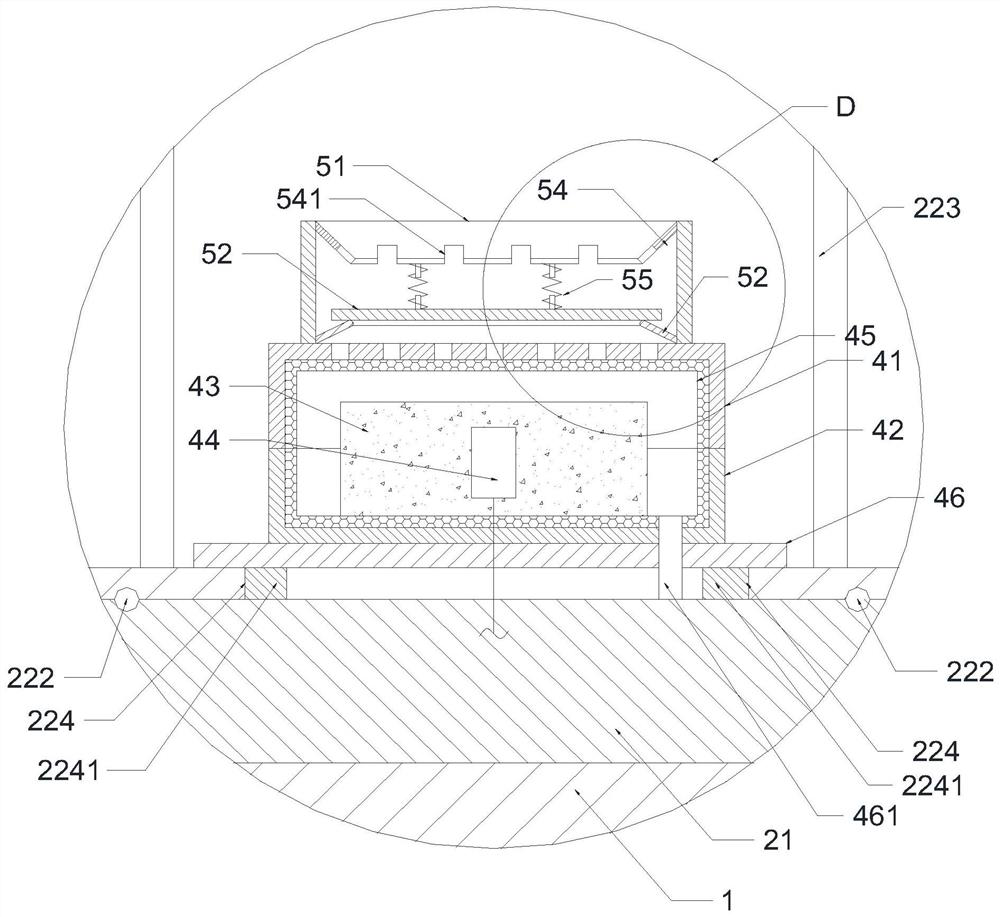

[0039] The base is installed in the box frame 1, and the base includes a base plate 21, an air bag 22, and a deformable cover plate 23;

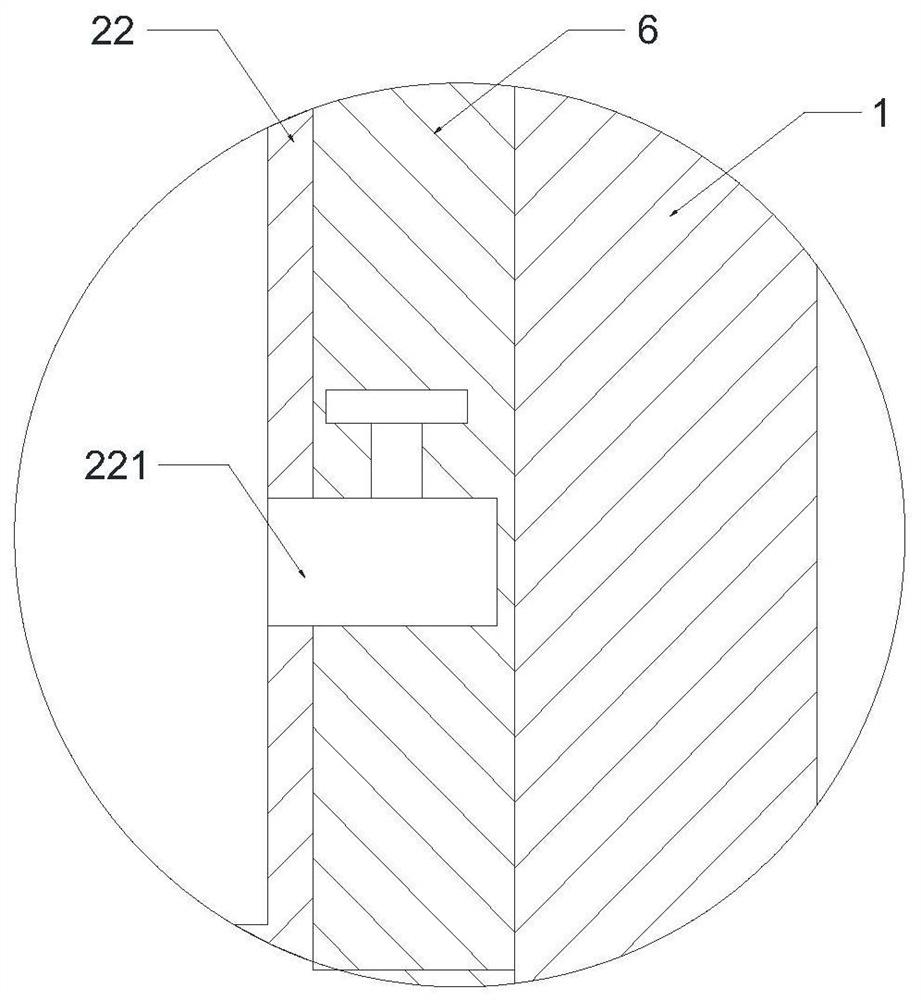

[0040] The airbag 22 is provided with a gas generator; both sides of the airbag 22 are respectively provided with sealable connecting pipes 221; the cover plate 23 is located on the upper surface of the airbag 22; the upper surface of the cover plate 23 is coated with a thermosetting resin 231;

[0041] The cladding unit 3 is located on the inner side of the side plate of the case frame 1 . The cladding unit 3 may use elastic air chambers or other shock-absorbing materials.

[0042] Through the variable characteristics of the airbag 22, the airbag 22 can be completely contacted with the bottom of the engine, so that the weight of the engine can be evenly shared. (as adopting high-temperature and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com