Device and method for printing three-dimensional pattern in form of varnish spraying

An inkjet printing and varnish technology, applied in printing devices, printing, typewriters, etc., can solve the problems of inability to meet the individual requirements of customers, inability to complete variable information reproduction, printing difficulties, etc., to achieve flexible production methods, improve blind people. User experience, the effect of reducing the number of prints required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

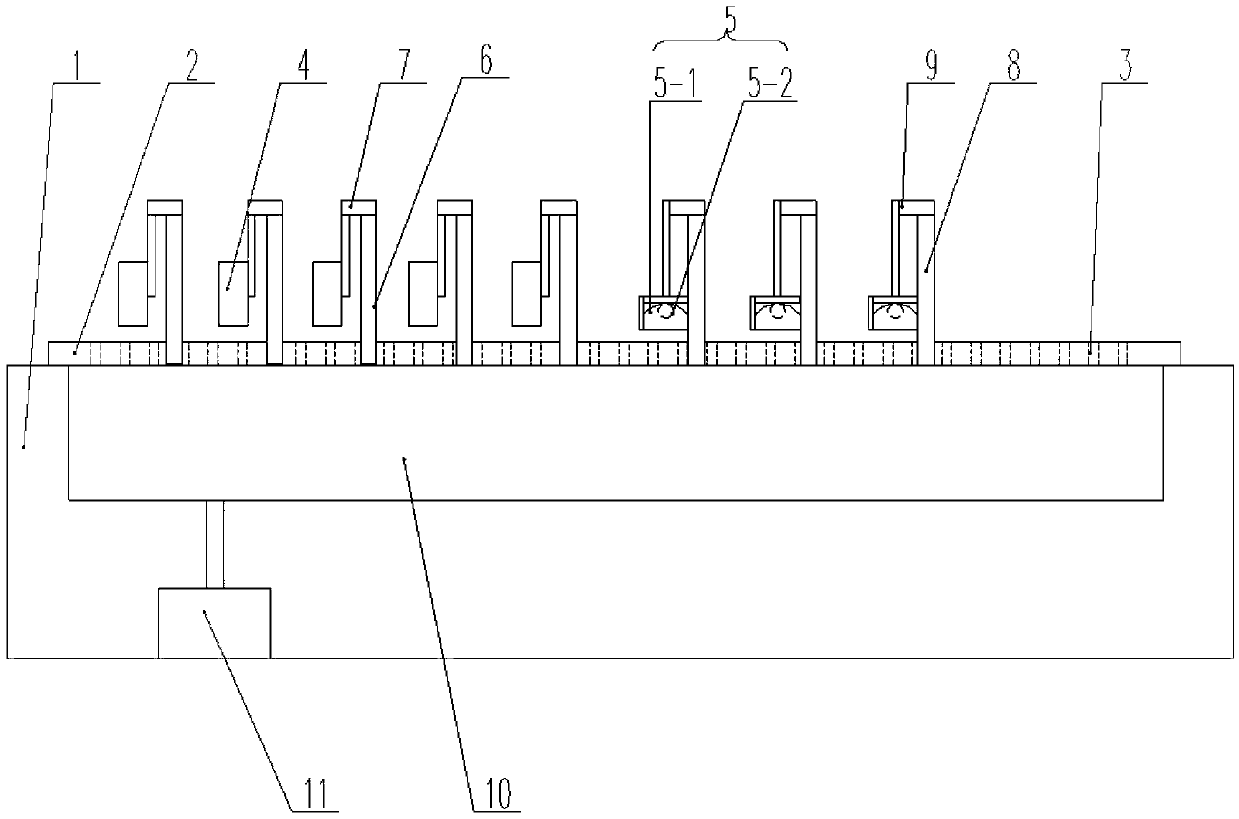

[0031] Such as figure 1 As shown, the embodiment of the present invention includes a printer bed 1 and a controller (in this embodiment, the controller can adopt lathe control systems commonly used in the prior art such as the EP2C35F672 chip of the Cyclone II series), and the printer bed 1 There is a printing platform 2 for carrying substrates, the printer bed 1 is provided with a negative pressure adsorption mechanism, and the printing platform 2 is uniformly provided with a plurality of adsorption holes 3 communicating with the negative pressure adsorption mechanism; The printer bed 1 is provided with a plurality of inkjet printing mechanisms 4, and the plurality of inkjet printing mechanisms 4 are arranged verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com