Adjustable type concrete precast block mold wide in application range

An adaptable and adjustable technology, applied in the direction of molds, etc., can solve the problems of waste of mold resources, lack of leveling devices for molds, single size, etc., to achieve the effect of ensuring levelness, quality assurance, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

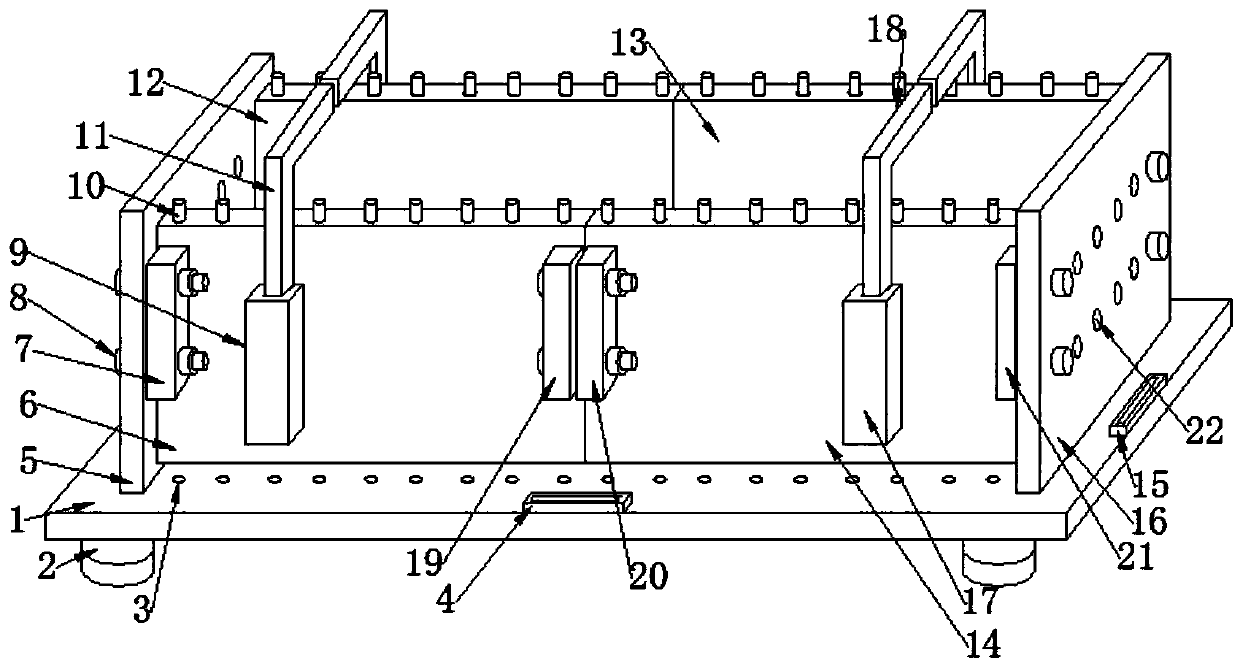

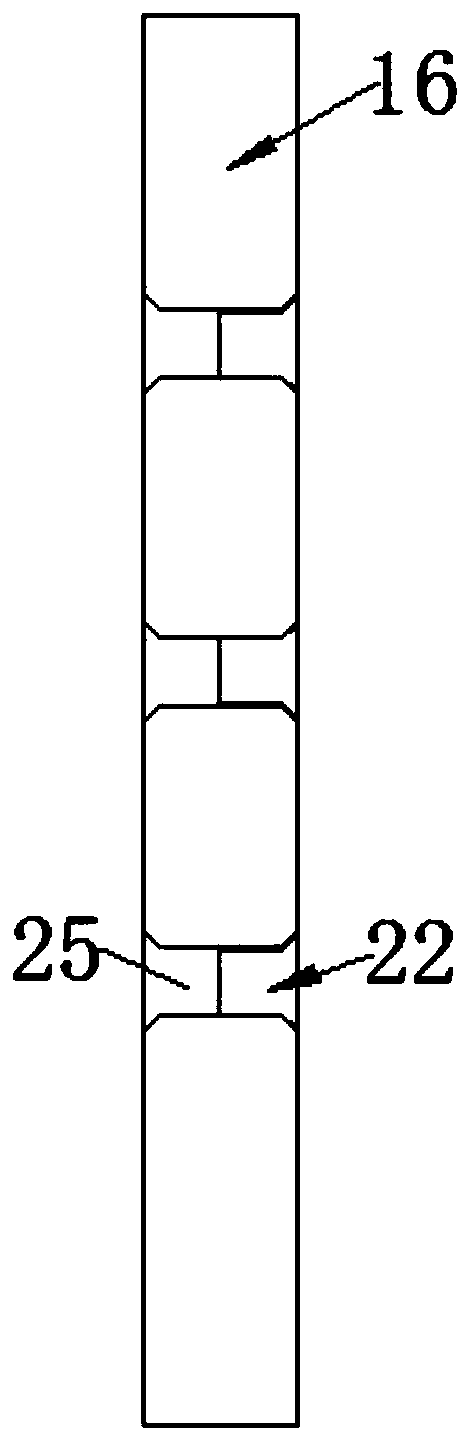

Embodiment 1

[0029] Embodiment one, with reference to Figure 1-7 , an adjustable prefabricated concrete block mold with a wide range of adaptability, including a support base 29, a leveling bolt 2 and a bearing 30, the upper side of the support base 29 is provided with the leveling bolt 2, and the leveling bolt 2 is The bearing 30 is arranged on the side, and a rotating rod 31 is arranged in the bearing 30, and the rotating rod 31 can rotate around the bearing 30. The upper side of the rotating rod 31 is provided with a base plate 1, and the upper side of the base plate 1 A No. 1 end plate 5 is provided, and a No. 1 side plate 6 is arranged on one side of the No. 1 end plate 5. A No. 1 fixing block 7 is arranged on the side of the No. 1 side plate 6 near the No. 1 end plate 5. A fixing bolt 8 is arranged in the No. 1 fixing block 7, and the No. 1 end plate 5 can be fixed by the No. 1 fixing block 7 and the fixing bolt 8. The upper and lower ends of the No. 1 side plate 6 are provided with...

Embodiment 2

[0030] Embodiment two, refer to figure 1 and Figure 7 , the support base 29 is threadedly connected to the leveling bolt 2, the leveling bolt 2 is connected to the rotating rod 31 through the bearing 30, the rotating rod 31 is welded to the bottom plate 1, and the The rotating rod 31 can rotate in the bearing 30 , and the support base 29 can rotate around the bearing 30 .

Embodiment 3

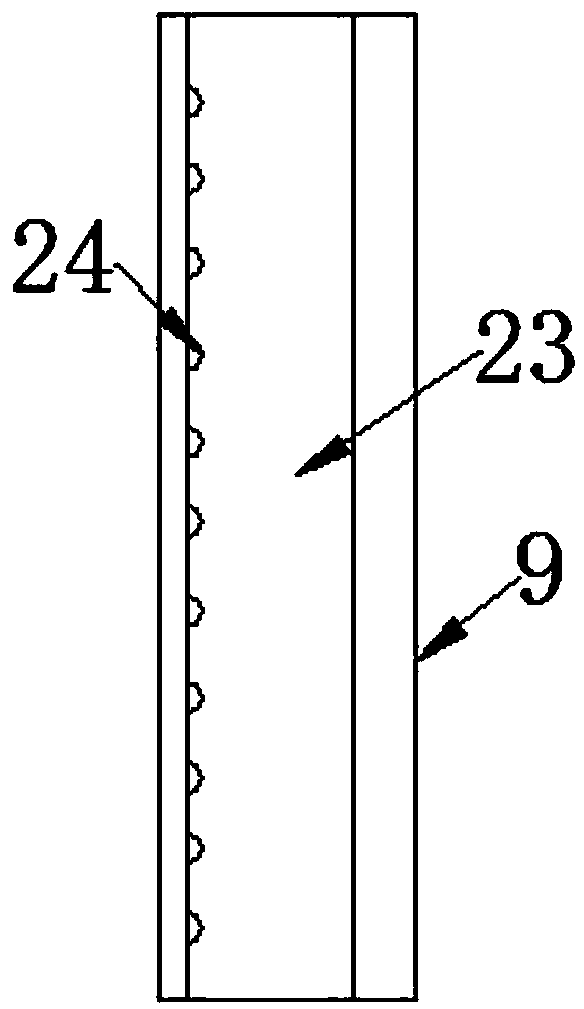

[0031] Embodiment three, refer tofigure 1 and Figure 7 , the bearing 30 is connected to the leveling bolt 2 through rotation, the bearing 30 is connected to the rotation rod 31 through rotation, and the bottom plate 1 and the No. 1 side plate 6 pass through the socket 3 and the The insertion rod 10 is connected, the insertion rod 10 is inserted into the insertion hole 3, and the No. 1 side plate 6 can provide side support for the concrete prefabricated block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com