Seed arranging system of full-electrically driven seed arranging potato precision planter

A potato and seeder technology, applied in the field of agricultural machinery and its electrical automation, can solve the problems of self-clogging compensation of potato seeds, complex structure, unstable machine operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

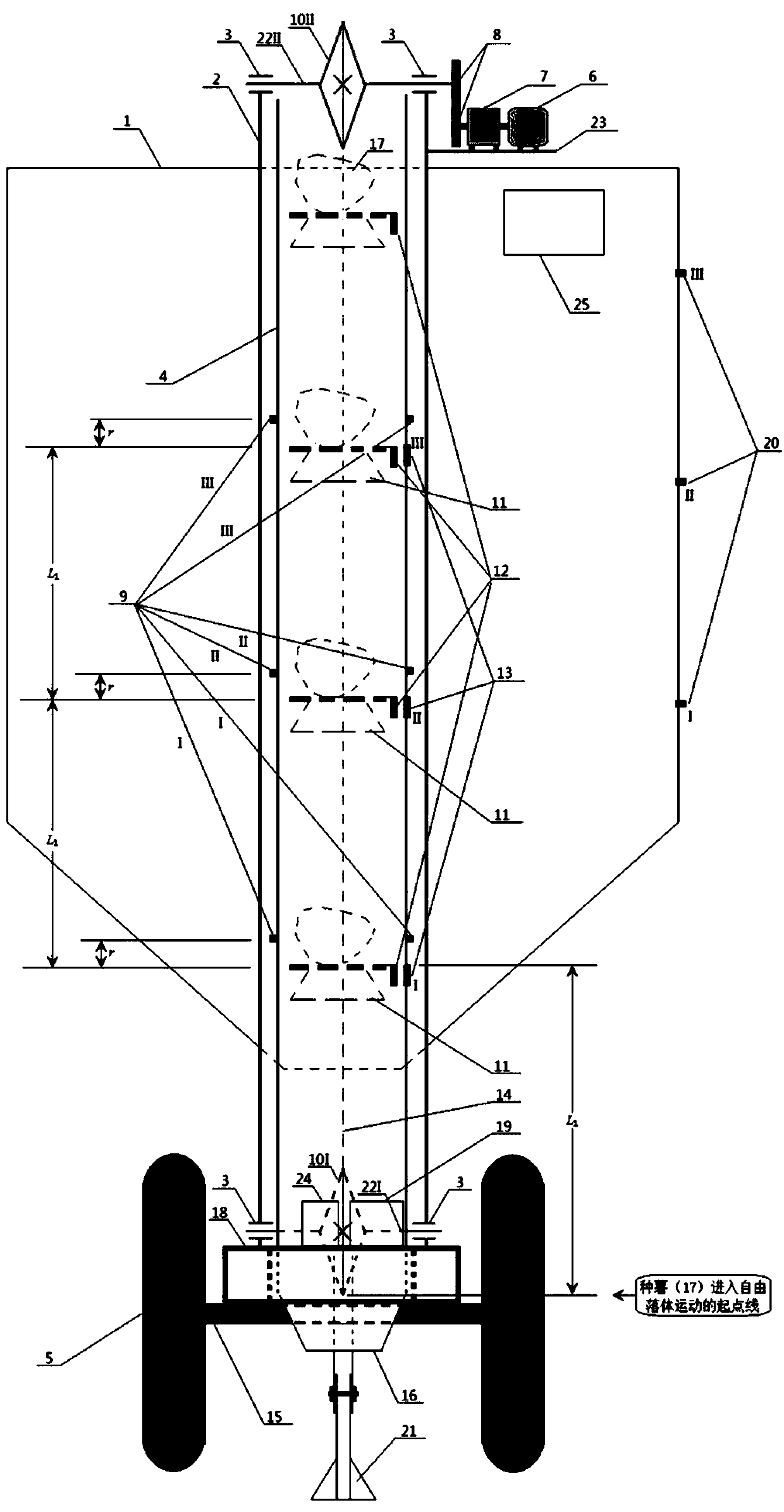

[0046] Below in conjunction with accompanying drawing, the present invention is described in further detail:

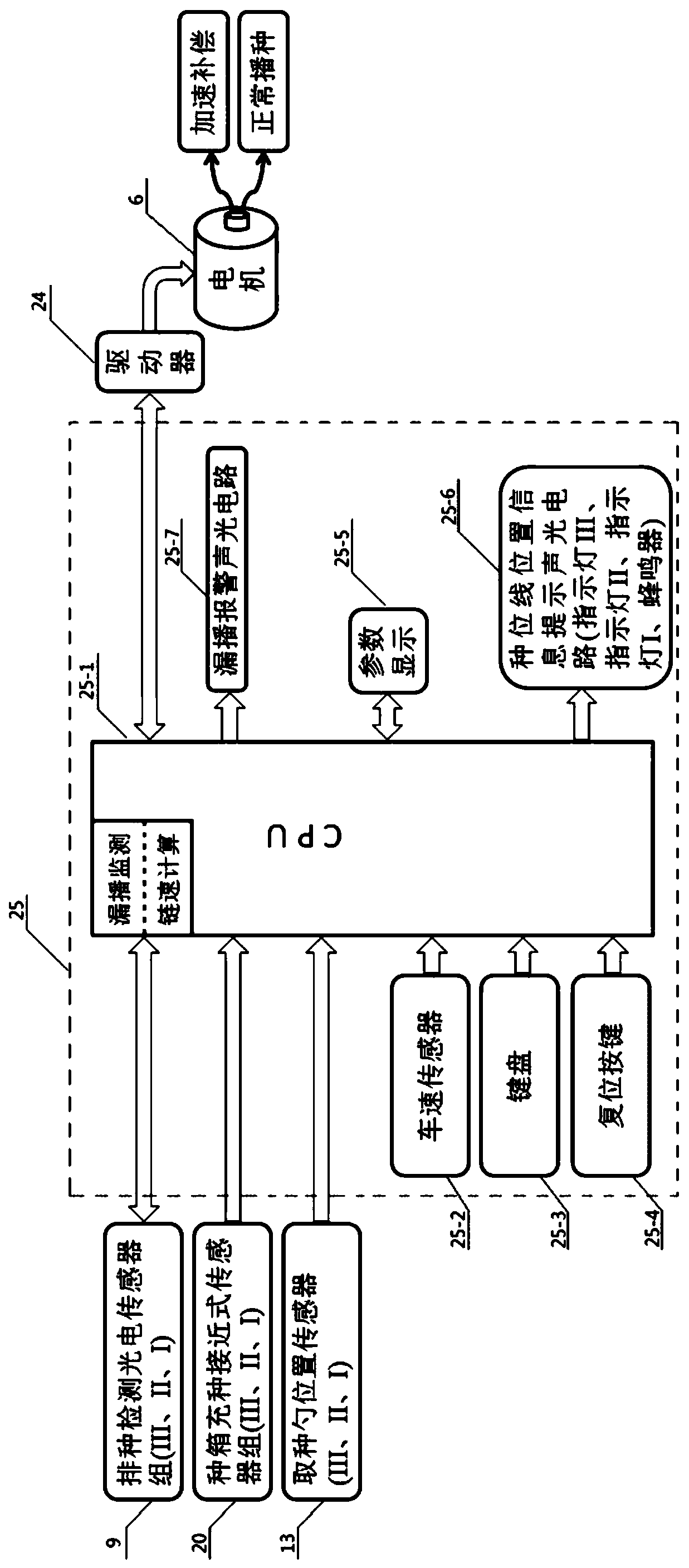

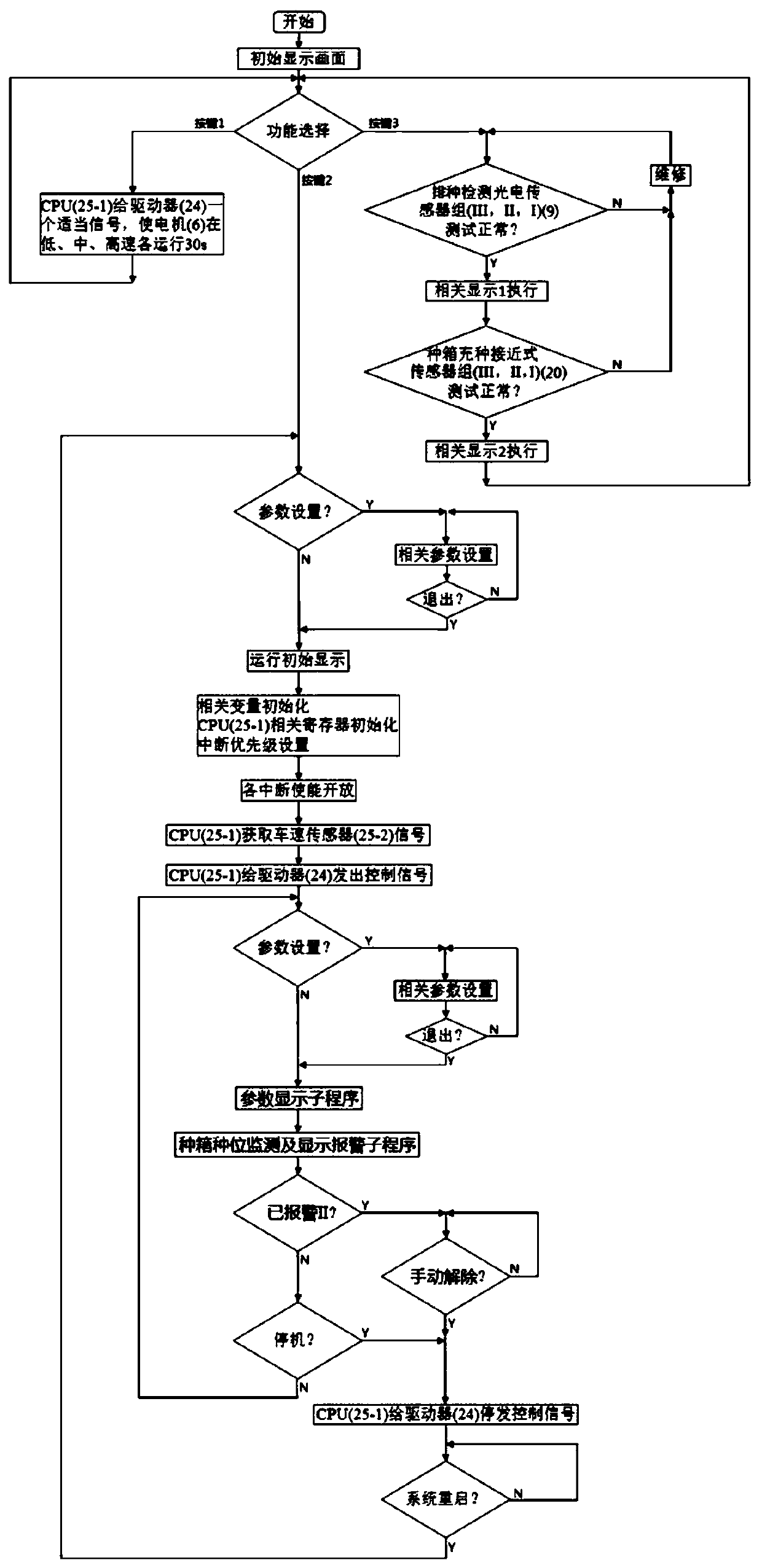

[0047] like figure 1 As shown, a seeding system of an all-electric drive seeding potato precision seeder includes a seed box 1, a frame vertical beam 2, a sprocket bearing 3, a seeding trough 4, a ground wheel 5, a motor 6, a reducer 7, Power transmission gear set 8, seed arrangement detection photoelectric sensor group (III, II, I) 9, seed arrangement sprocket (II, I) 10, seed picking spoon 11, seed picking spoon position signal carrier 12, seed picking spoon Position sensor (III, II, I) 13, seed-discharging chain 14, ground wheel shaft 15, seed-discharging trough seeding opening 16, seed potato 17, frame bottom beam 18, vehicle-mounted storage battery 19, seed box filling kind proximity sensor ( III, II, I) 20, position-adjustable ditch opener 21, sprocket shaft (II, I) 22, seeding power installation base plate 23, driver 24 and system controller 25.

[0048] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com