Sewing machine with a bobbin case changing device

A sewing machine and bobbin case technology, which is applied to sewing machine components, sewing machine center bobbin winding, sewing equipment, etc., to achieve the effect of compact bobbin case replacement device and shorten non-production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

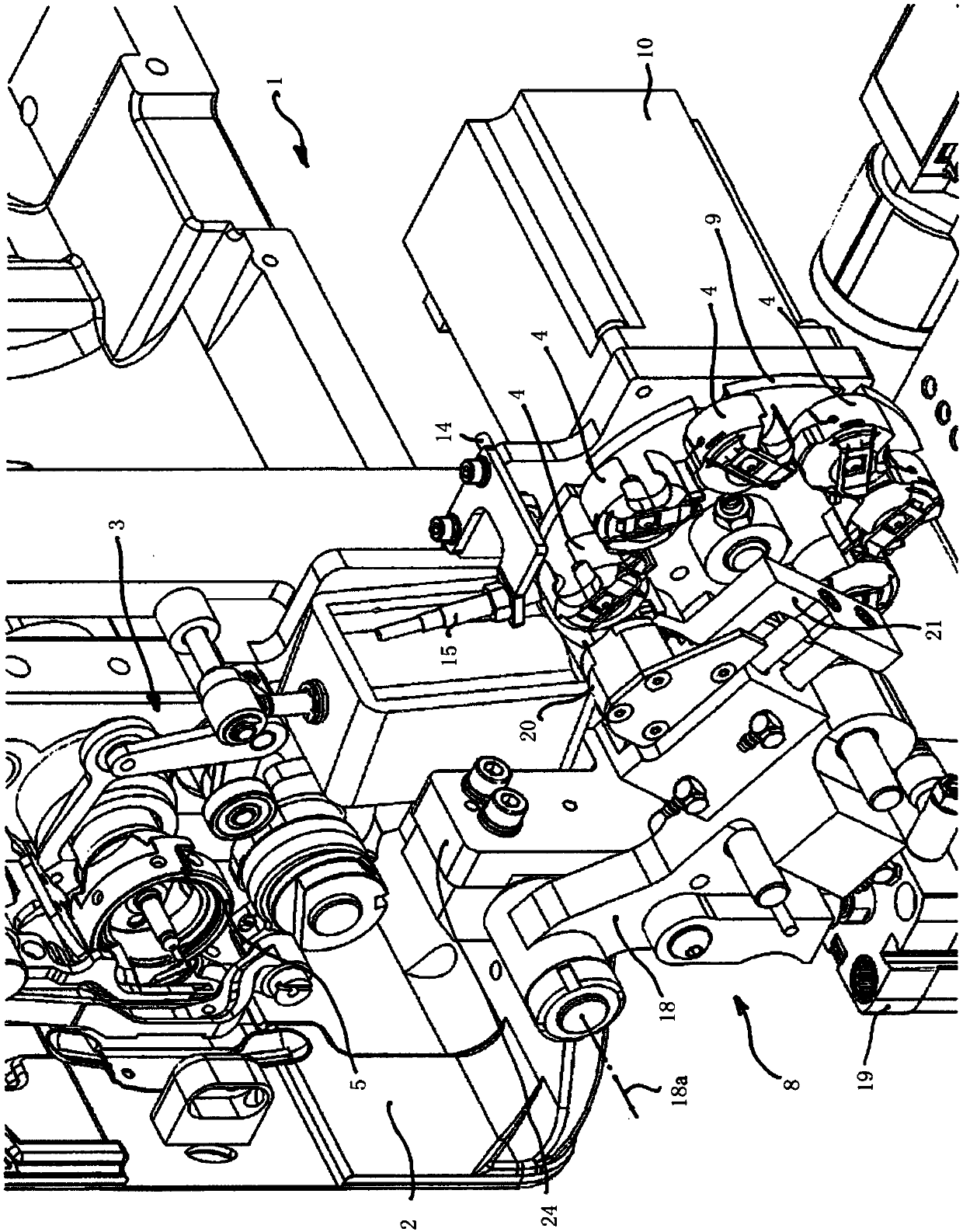

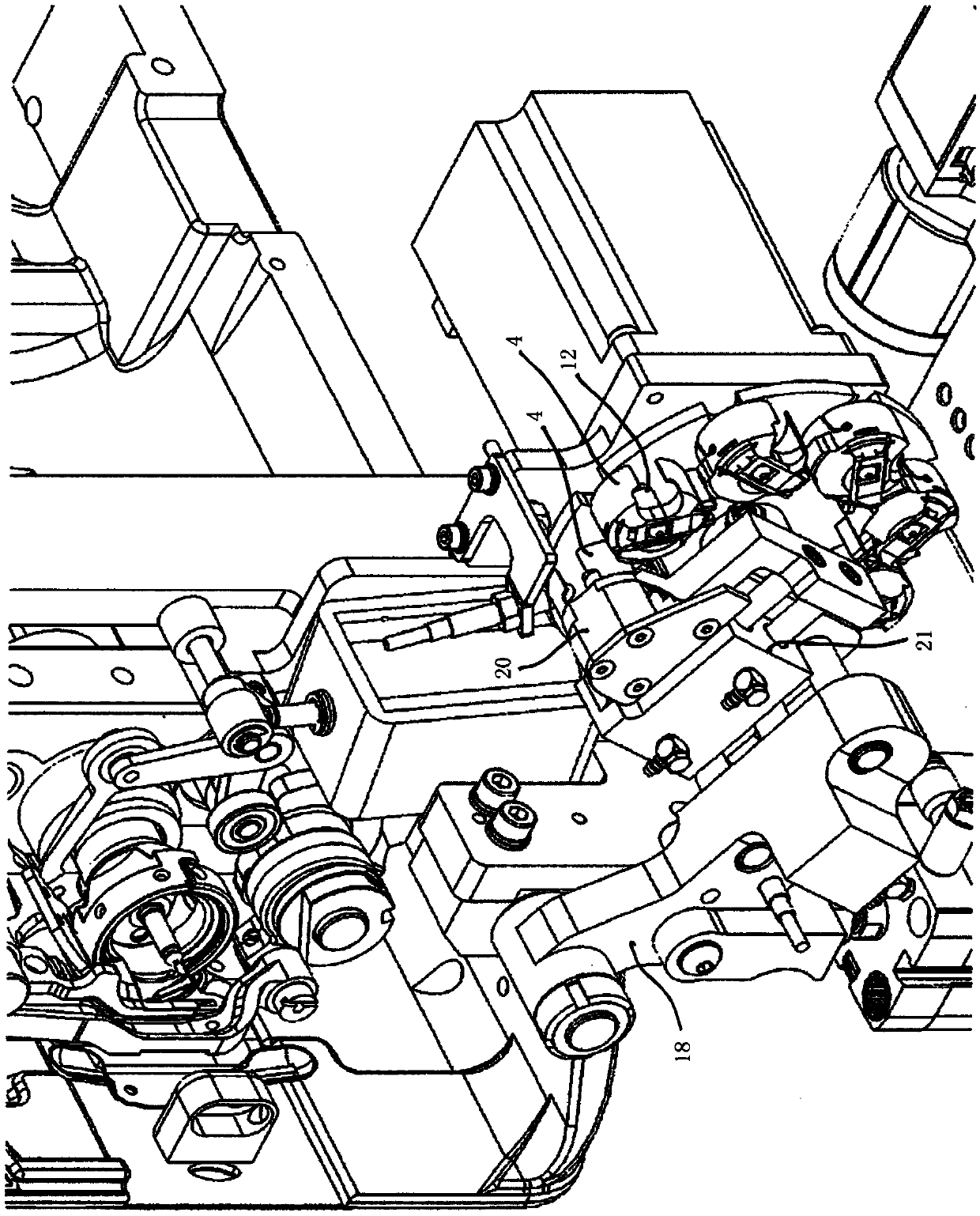

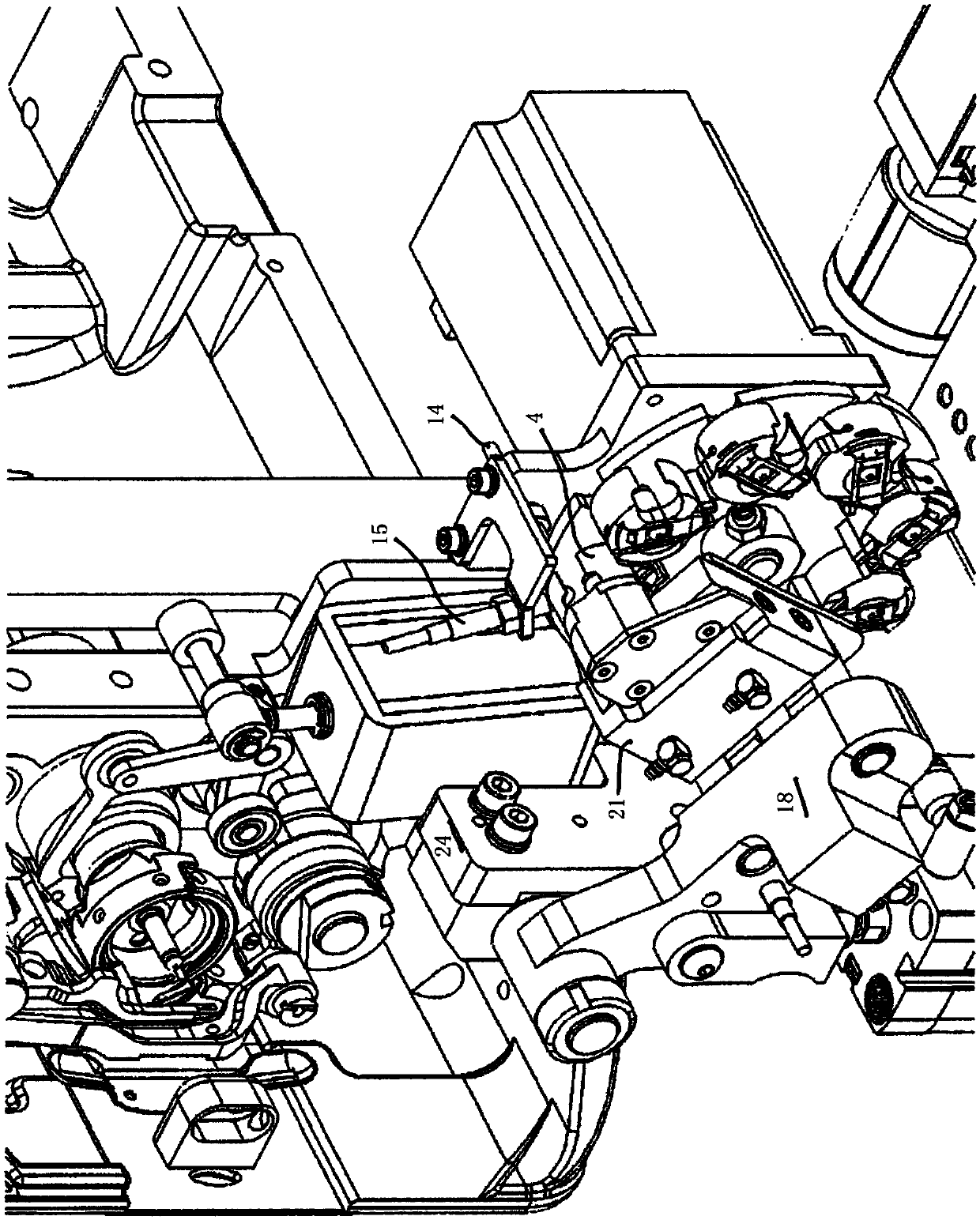

[0021] exist figure 1 In the only partial view, an example of a sewing machine 1 constructed as a double backtack sewing machine is shown, the housing 2 of which has a lower housing-shaped so-called base plate, from which the stand 3 extends approximately vertically upwards. The upper end of the stand is connected to an arm substantially parallel to the bottom plate 2 .

[0022] The sewing machine has an arm shaft supported in the arm, which is also not present in the same way as other basic components of the sewing machine described below. figure 1 shown in or as the case may be only partially or greatly simplified. The arm shaft drives a needle bar that can move back and forth in an oscillating manner, and a needle for accommodating (not shown) upper thread can be fixed on the needle holder of the needle bar. Arranged on the base plate 2 is a hook device 3 with a rotary hook, the rotary movement of which is synchronized with the oscillating movement of the needle bar. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com