Polymer composition for selective sintering

A technology of polymers and compositions, applied in the direction of 3D object support structure, processing and manufacturing, manufacturing tools, etc., can solve the problems of no continuous use temperature, no high melting point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] Example 1 represents an embodiment of the invention, and Examples 2-4 are included for comparative purposes.

[0154] Subject the above materials to use including CO 2 Selective laser sintering method of Mini-SLS machine with laser source. During each laser sintering process, 4 square plates of 30x30x2 mm are produced. 0.05% by weight of Aerosil 200 flow promoter was added to each powder. The material was pre-dried and then processed via SLS. The SLS method is carried out in an atmosphere with an oxygen content of ≦1.0% by weight. The SLS method conditions are shown in Table 2. The moisture content of the atmosphere is <50ppm.

[0155] Table 2: SLS Processing Conditions

[0156] Example 1 2(C) 3(C) 4(C) Powder bed temperature (℃) 225 173 140 213 Piston temperature (℃) 185 135 65 170 Cylinder temperature (℃) 145 110 65 180 Feed temperature (°C) 160 120 70 160 Laser power (W) 30 21 21 9 Scanning speed (m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization time | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

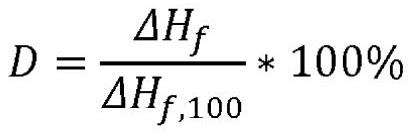

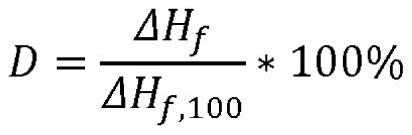

| enthalpy of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com