A bridge non-contact deformation measurement method based on feature point tracking

A non-contact, measurement method technology, applied in image data processing, instruments, calculations, etc., can solve the problems of cumbersome layout and acquisition system, and achieve the effect of abundant SURF detection, fast calculation speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

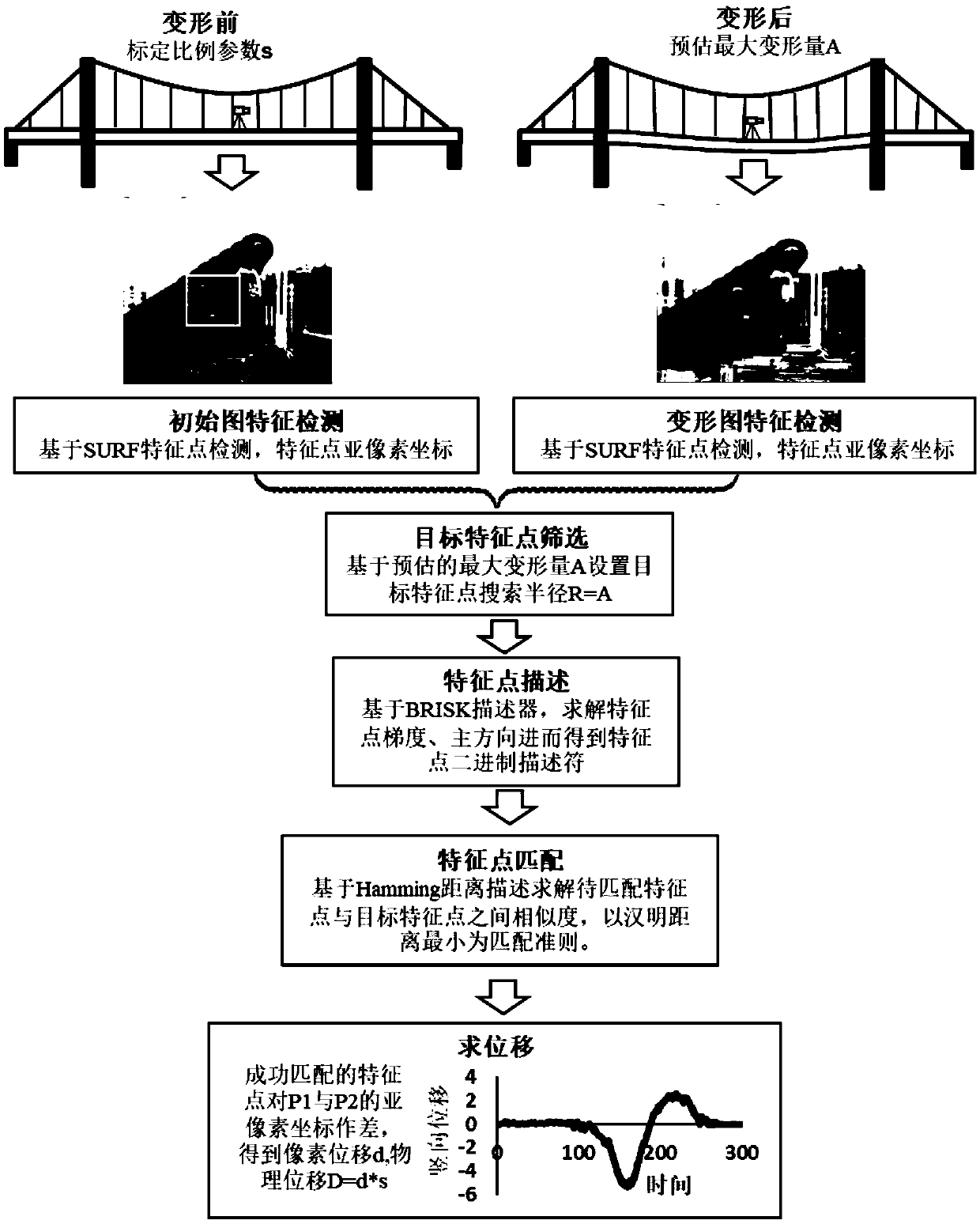

Method used

Image

Examples

Embodiment 1

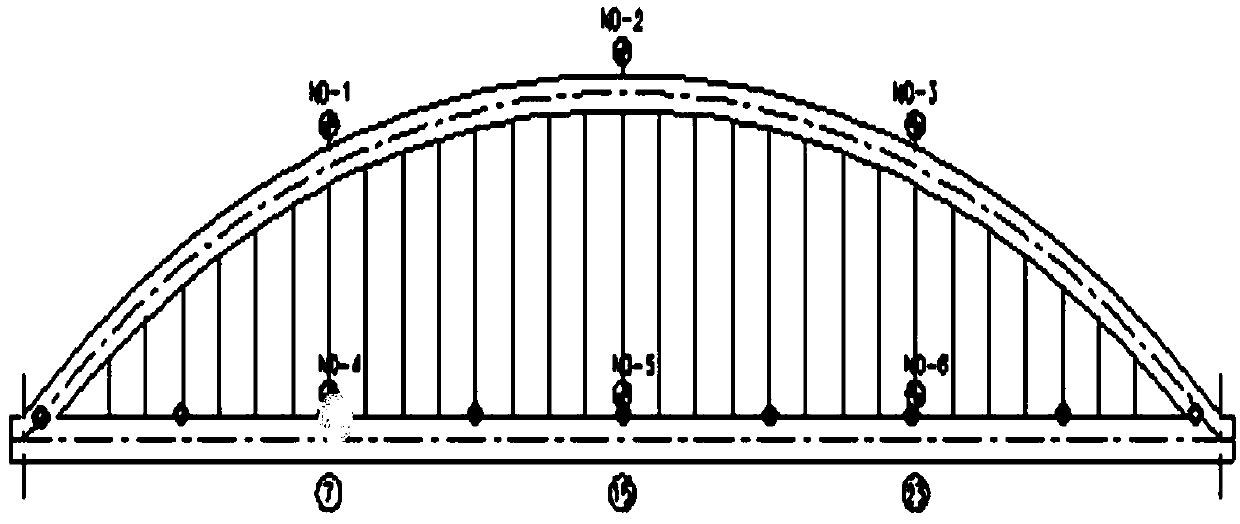

[0037] In the following, a typical bridge load test case is used to illustrate the implementation steps of the proposed rapid bridge deformation measurement method based on feature point tracking. First of all, let me introduce the static load test conditions measured by optical measurement on the same day. Six trucks with a single vehicle weight of 34 tons are used for loading. After the bridge deck is empty, the trucks are ready at the bridge head and stop at each eighth test point, such as image 3 As shown in , this optical measurement needs to monitor the deflection near the green measuring point. Each octant measuring point should stop for at least 10 minutes to ensure that the structure is completely deformed. The traditional measuring equipment used to measure the deformation of each octant measuring point on that day includes a level and an inclinometer. The following are the implementation steps when photometry is involved:

[0038] Step 1: Determine the layout of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com