A virtual factory service collaboration system based on a digital twinning technology

A collaborative system and virtual factory technology, applied in the direction of manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as production delays, increase the probability of errors, and the difficulty of synchronous updates in the manufacturing process, so as to achieve safe and convenient use and speed up production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

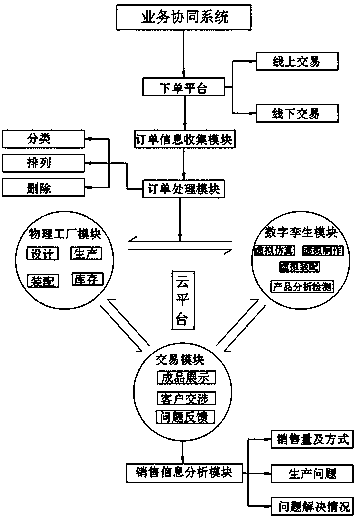

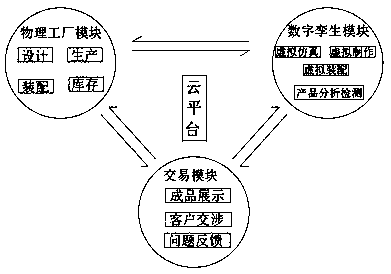

[0020] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a virtual factory business collaboration system based on digital twin technology, including a business collaboration system, and the business collaboration system includes an order platform, an order information collection module, an order processing module, a physical factory module, Cloud platform, digital twin module, transaction module, sales information analysis module, order platform includes online transaction and offline transaction, both online transaction and offline transaction are connected to the order platform, and the order platform is connected to the order information collection module , the order information collection module and the order processing module. The order processing module includes classification, arrangement and deletion. The order processing module is connected with the physical factory module, digital twin module and transaction module through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com