LIBS (Laser-induced Breakdown Spectroscopy) intelligent online rapid detection system for coal quality

A detection system and coal quality technology, which is applied in the field of LIBS coal quality online intelligent rapid detection system, can solve problems such as burnout of the burner and primary air duct, explosion of the pulverizing system, guidance basis, etc., to achieve convenient installation and maintenance, accurate coal quality components, the effect of accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

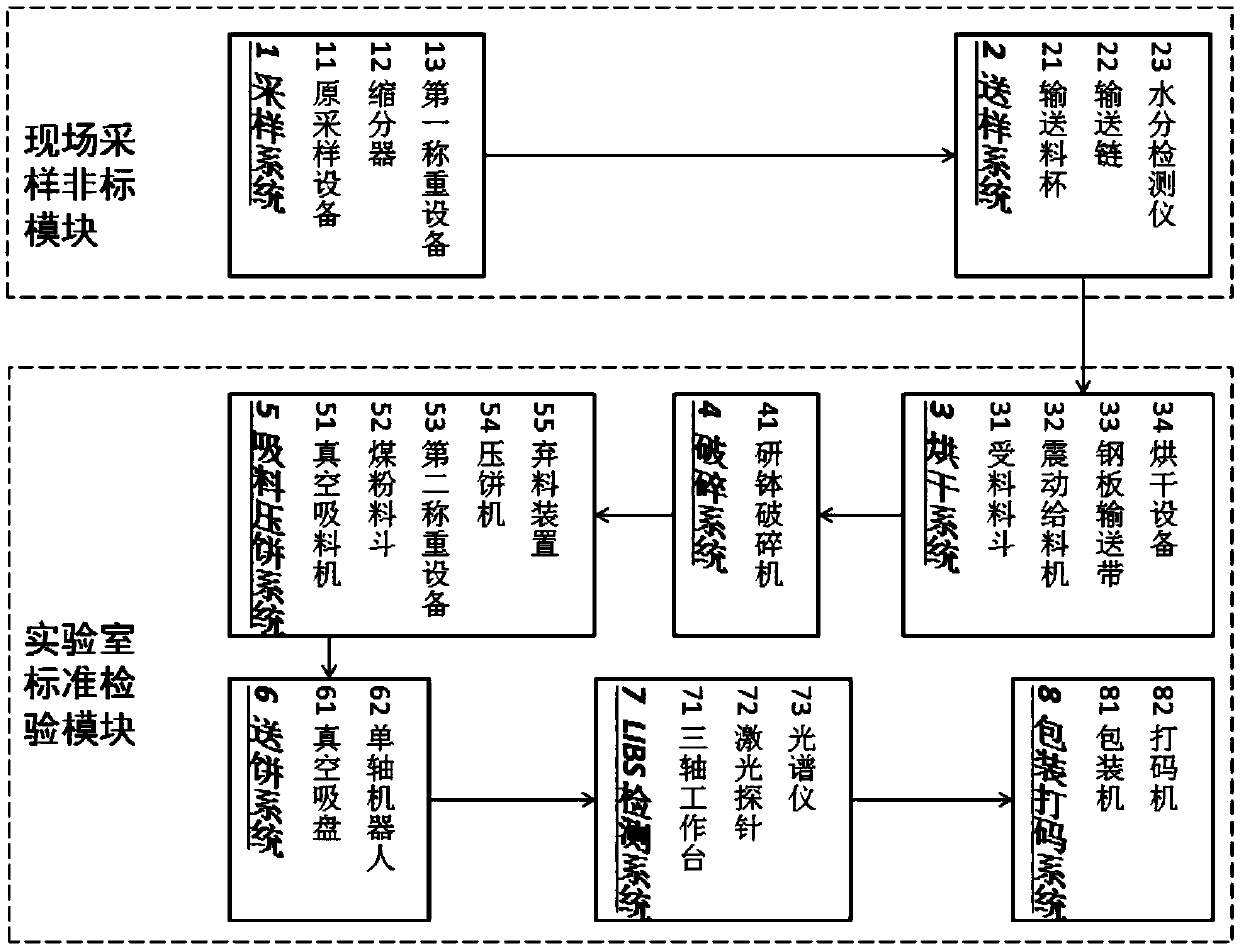

[0024] see figure 1 As shown, the LIBS coal quality online intelligent rapid detection system of the present invention includes a sampling system 1, a sample delivery system 2, a drying system 3, a crushing system 4, a suction cake pressing system 5, a cake delivery system 6, LIBS detection System 7, packaging and coding system 8 eight modules are designed, each system module is independently produced, assembled and transported, and the excessive transmission system between the modules is placed and designed according to different site conditions, in which the sampling system 1 and the sample delivery system 2 are arranged in In the existing sampling room, there are non-standard design modules. The drying system 3, the crushing system 4, the cake suction system 5, the cake delivery system 6, the LIBS detection system 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com