Clutch control method for vehicle

A clutch and controller technology, applied in the field of clutches, can solve problems such as power transmission loss, achieve the effect of improving driving quality and preventing collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description is merely exemplary in nature and is not intended to limit the invention, application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

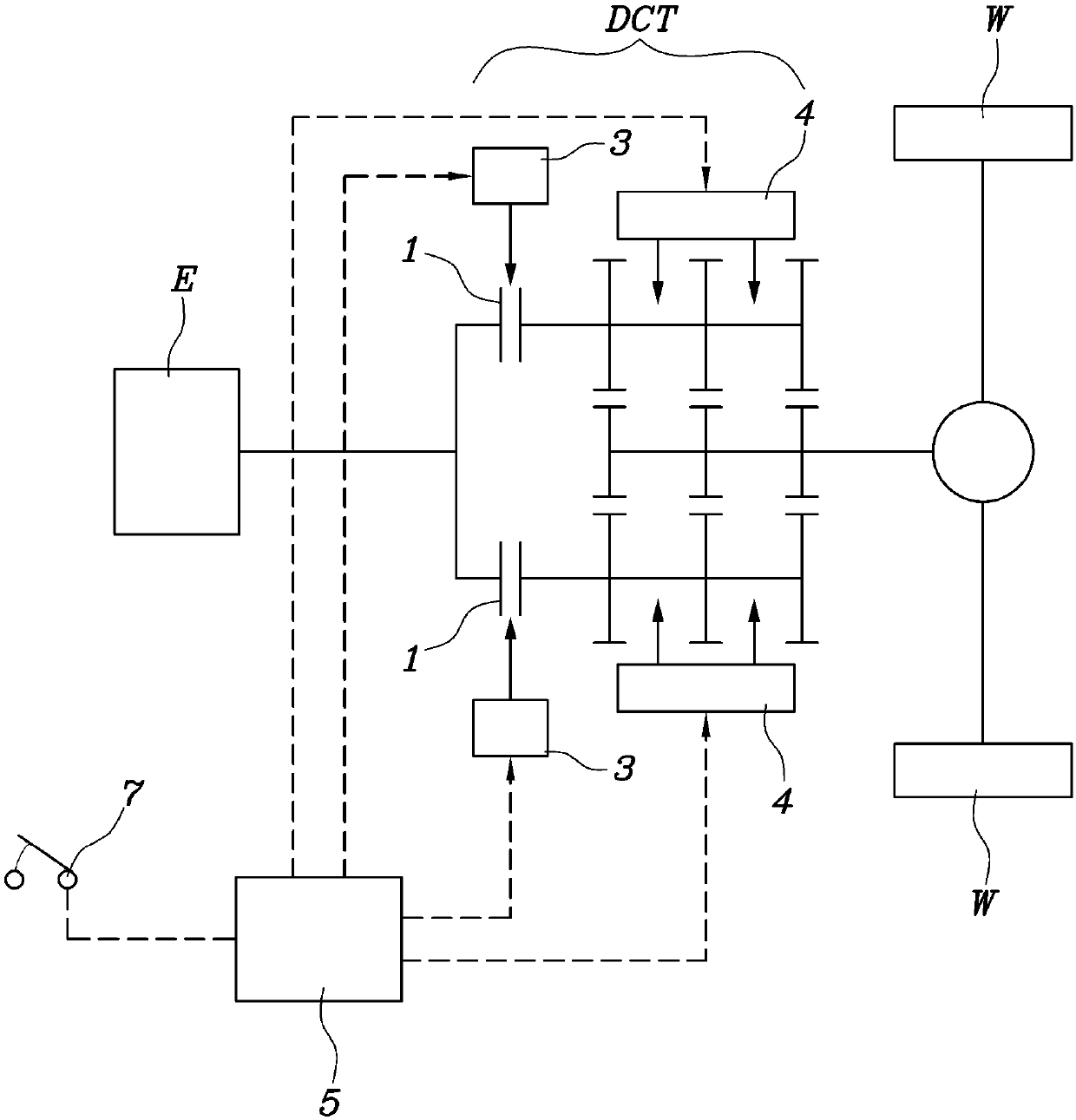

[0023] see figure 1 , the power source of the engine (E) is configured to be supplied to the drive wheels (W) via a dual clutch transmission (DCT); the two clutches 1 constituting the DCT are respectively controlled by the clutch actuator 3; The shift gear is shifted by a shift actuator 4, which selects and drives the synchronizing device; the clutch actuator 3 and the shift actuator 4 are controlled by a controller 5; the controller The signal of the accelerator position sensor (APS) 7 is received to receive the operation amount of the accelerator pedal.

[0024] Of course, in addition to the above information, the controller 5 also receives information such as engine torque and engine speed information.

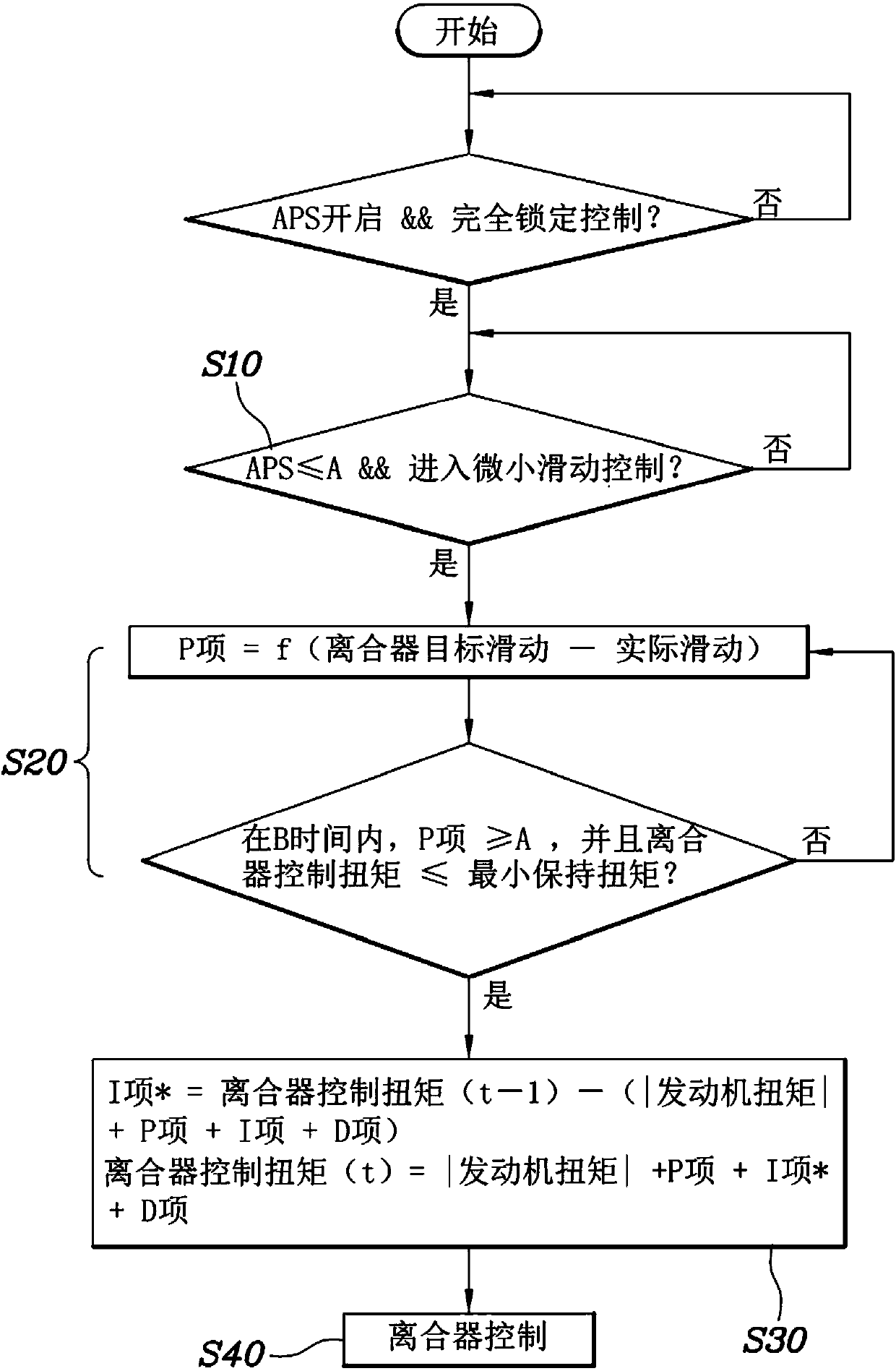

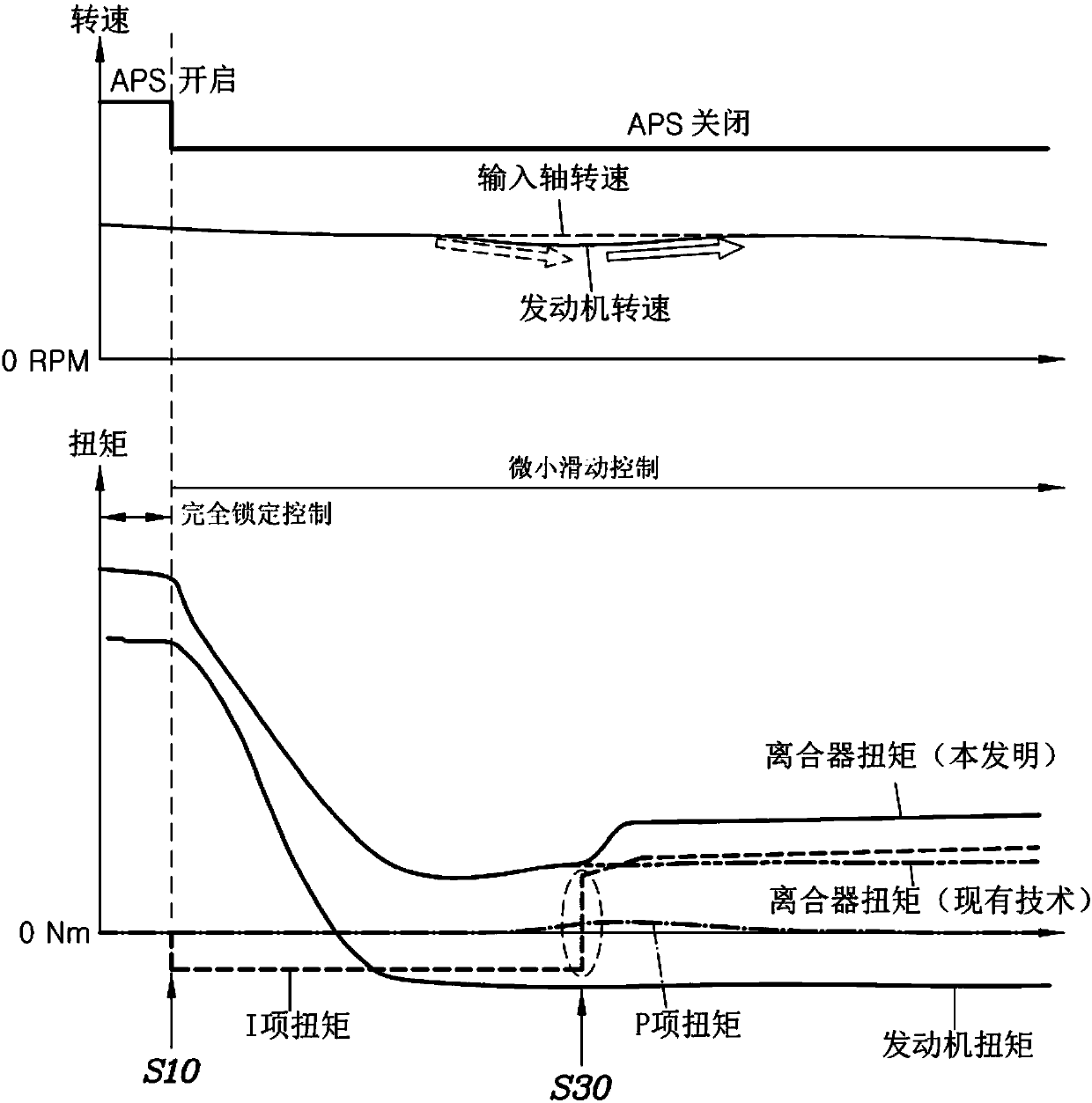

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com