Simple two-shaft rotating mechanism with double teeth folded outwards

A rotating mechanism and simple technology, applied in the direction of pivot connection, etc., can solve the problem that the traditional rotating shaft cannot meet the functional requirements, and achieve the effect of precise positioning and connection, and simple structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

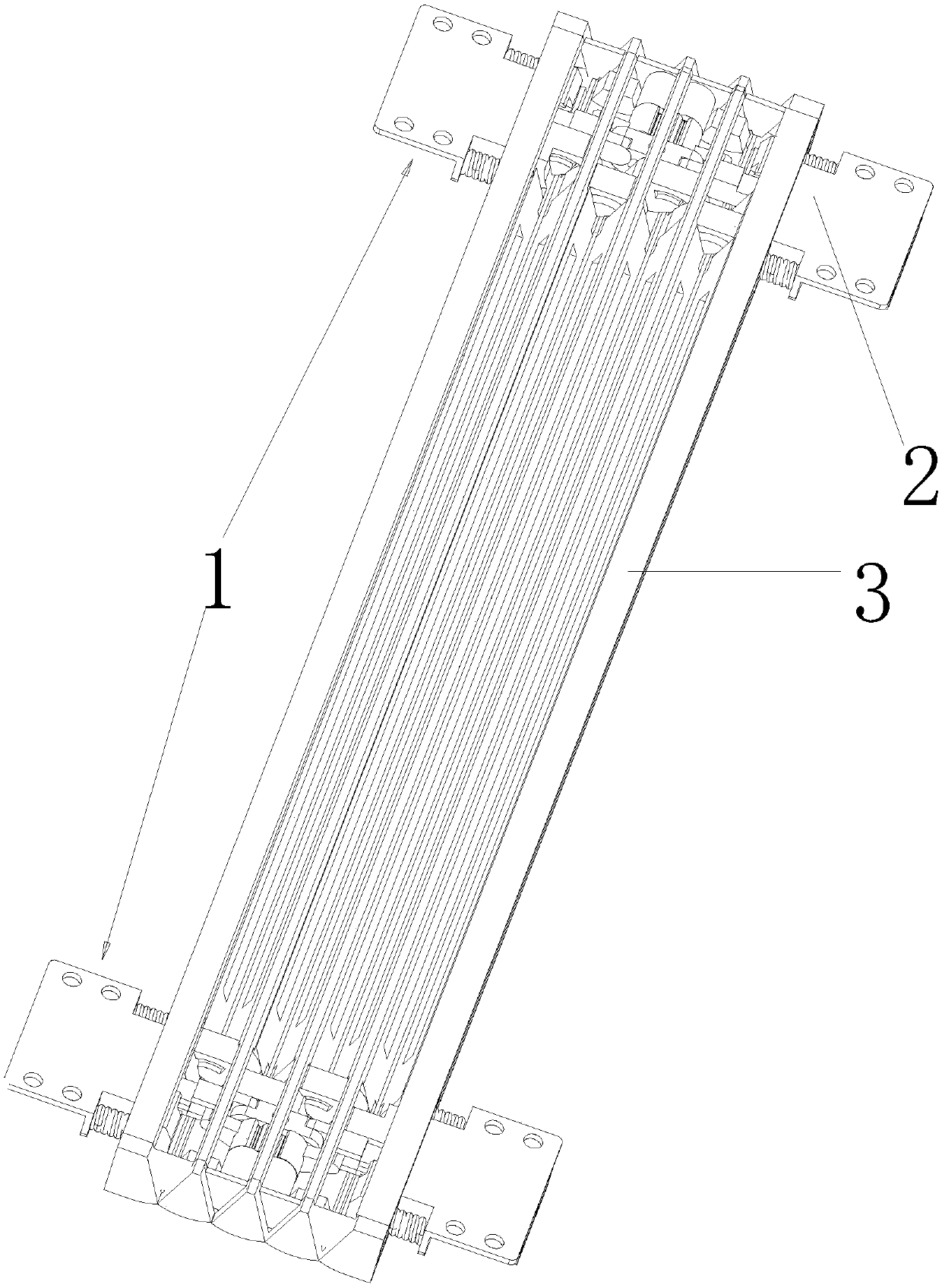

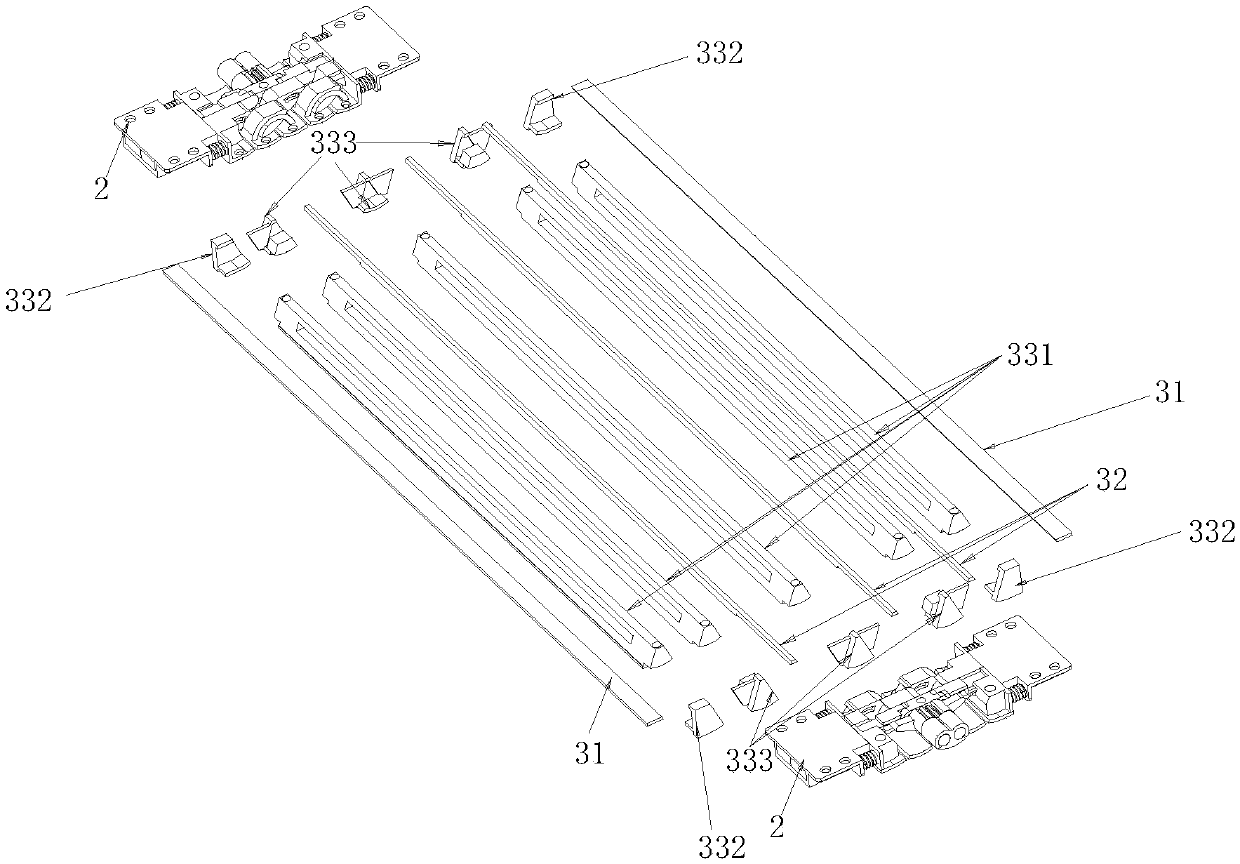

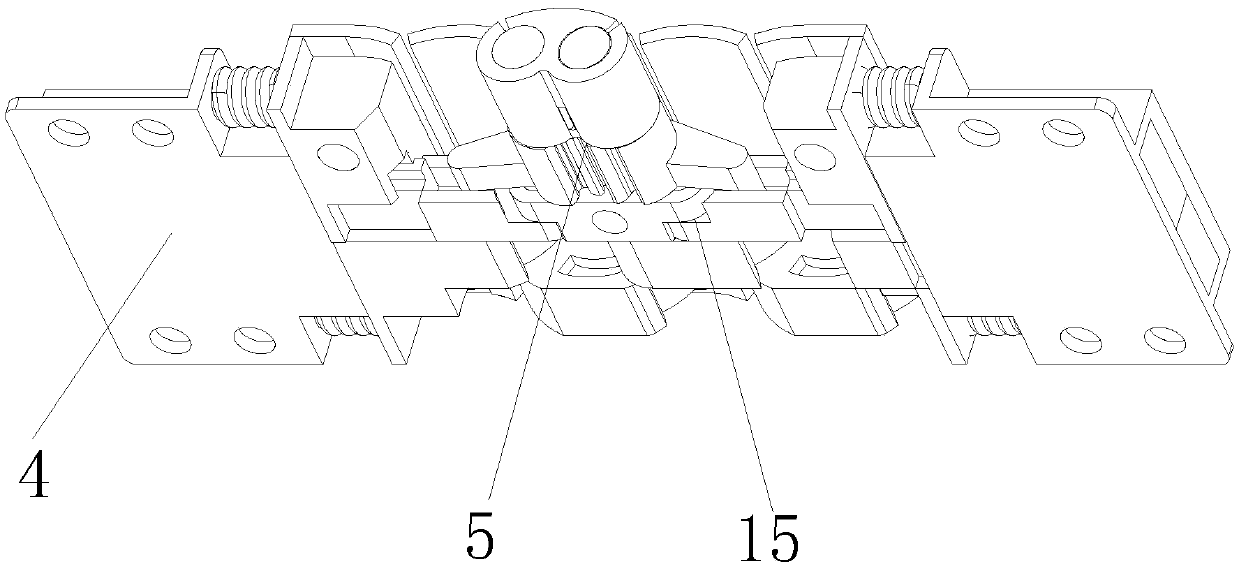

[0026] Such as Figure 1-10 As shown, a simple two-axis rotating mechanism with double teeth folded outwards disclosed in this embodiment includes a structural main body 1, and the structural main body 1 is composed of two sets of outer folding shafts 2 and a package body 3; the outer folding shafts 2 It consists of a bilaterally symmetrical spring seat 4 and a double-tooth round-wrap mechanism 5 connected thereto. The double-tooth round-wrap mechanism 5 includes a damping round 6 and a connecting block 7 combined with it. The connecting block 7 and the damping round 6 are provided with a first gear shaft 8 and a second gear shaft 9 to realize synchronous rotation, and the double-tooth circle-wrapping mechanism 5 is rotatably connected with multiple sets of sliding blocks 15, and the sliding blocks 15 include two sets of side sliding blocks 11 And three sets of middle sliding blocks 12, the middle sliding block 12 is composed of the first middle sliding block 121 and two group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com