Novel bus duct convenient to use

A bus duct, a new technology, applied in the field of bus duct, can solve the problems of inserting the wire separator into the flame-retardant partition, low use efficiency, and poor wire partition, etc., to achieve high use efficiency, simple structure, and good heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

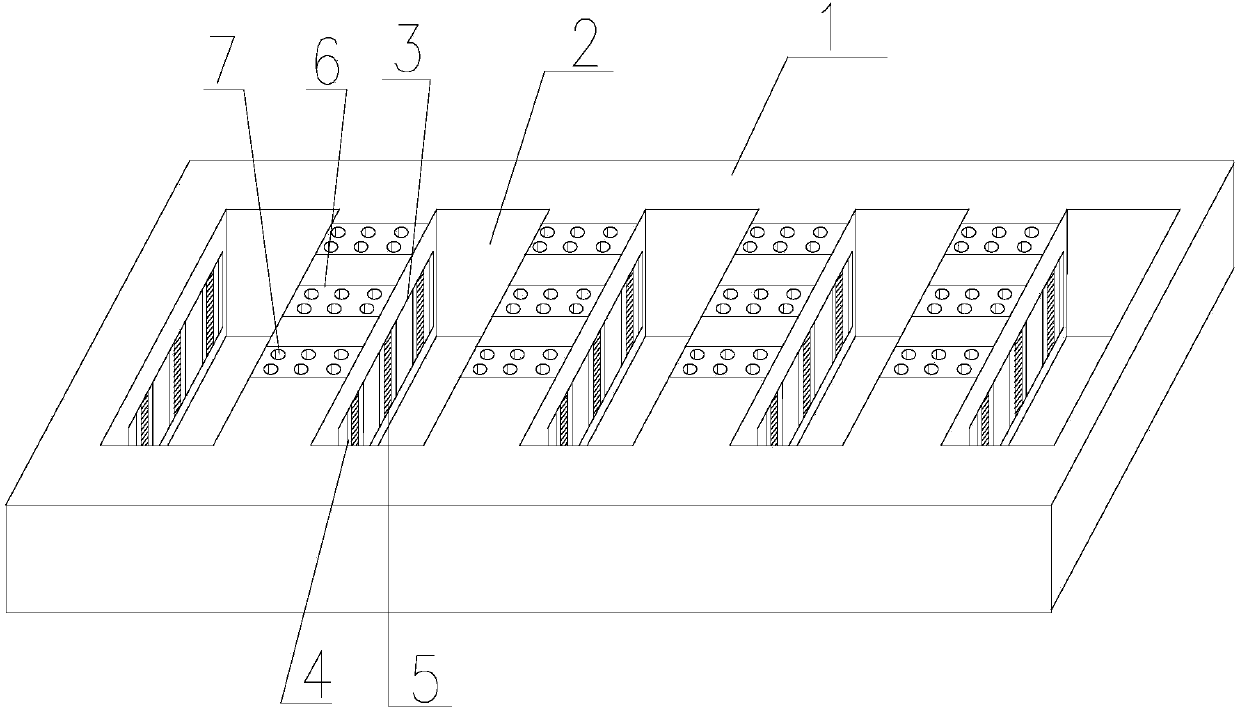

[0023] Such as figure 1 As shown, the easy-to-use novel busway of the present invention includes a busway body, and the busway body includes a flame-retardant partition 1 provided with several square holes 2 and a wire that passes through the square holes 2 and is vertically connected to the flame-retardant partition 1 Partition board, a first placement groove 3 is arranged between two adjacent square holes 2 on the flame retardant partition board 1, a number of second placement grooves 4 are arranged on the first placement groove 3, and a number of second placement grooves 4 are arranged in the second placement groove 4. Rotatable pulley 5, the axis of the pulley 5 is parallel to the plane where the flame retardant partition is located, and the diameter of the pulley 5 is the same as the distance between two adjacent square holes 2, when the wire partition is inserted into the square hole 2 , The wire partition is in contact with the side of the pulley 5, and the pulley 5 rot...

Embodiment 2

[0025] A new type of busway that is easy to use, on the basis of Embodiment 1, several convex lines are provided on the adjacent inner wall of the pulley 5 on the square hole 2 . In the flame-retardant partition 1, a heat dissipation layer 6 is arranged above the second placement groove 4, and a plurality of through holes 7 are arranged on the heat dissipation layer 6. One end of the through hole 7 runs through the upper end of the flame-retardant partition 1, and the other end of the through hole 7 One end runs through the lower end of the heat dissipation layer 6 and communicates with the second placement groove 4; the second placement groove 4 is also provided with a heat dissipation layer 6, and the heat dissipation layer 6 is provided with a plurality of through holes 7, and one end of the through hole 7 runs through the flame-retardant barrier. The lower end of the board 1 and the other end of the through hole 7 pass through the upper end of the heat dissipation layer 6 a...

Embodiment 3

[0027] A new type of busway that is easy to use, on the basis of Embodiment 2, the number of second placement slots 4 in the first placement slot 3 is not less than three, and the axes of the pulleys 5 in the second placement slots 4 are on the same straight line . The pulley 5 is provided with a rubber layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com