Fluorescent mixture and light-emitting device thereof

A light-emitting device and phosphor technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor chemical stability, limited spectral coverage, long-term light decay of light-emitting devices, etc., and achieve the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

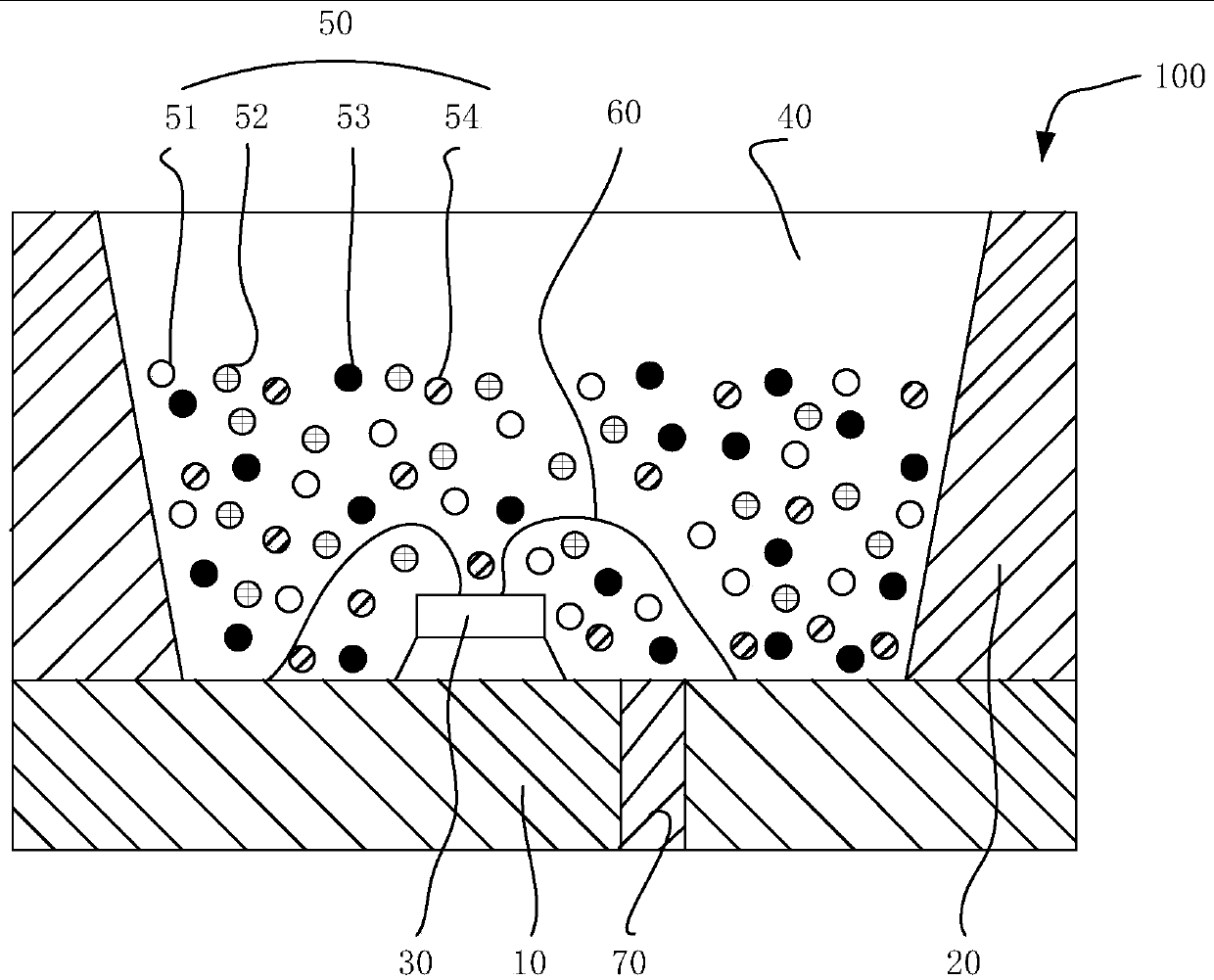

Method used

Image

Examples

Embodiment 1

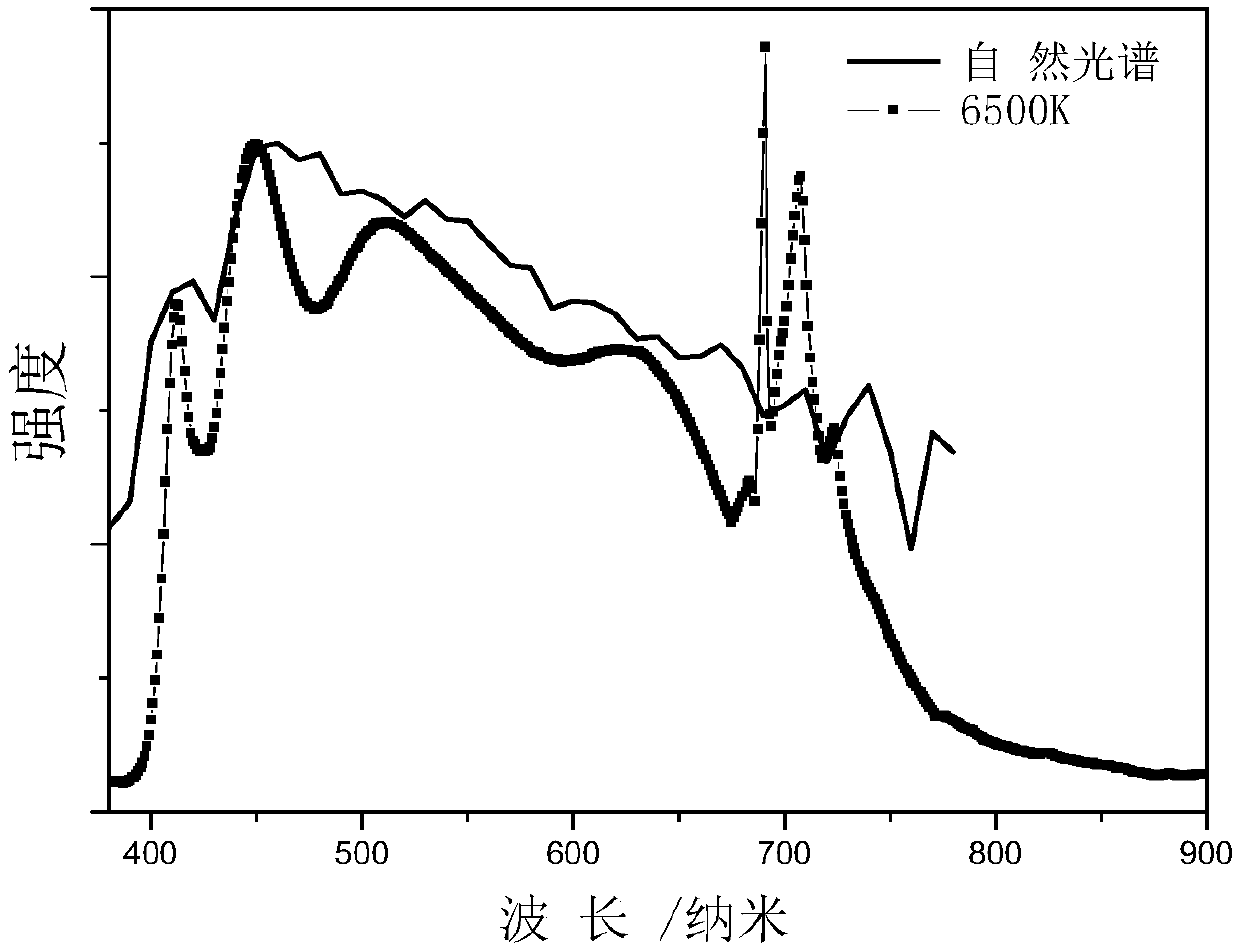

[0110] The LED chip chooses the purple LED chip with the emission peak wavelength of 405nm, the packaging glue chooses silicone resin, and the phosphor combination includes: the blue phosphor chooses the emission peak wavelength of 450nm (Sr, Ba) 5 (PO 4 ) 3 Cl:Eu 2+ Phosphor; yellow-green phosphor selects Y with emission peak wavelength of 530nm 3 (Al,Ga) 5 o 12 : Ce 3+ Phosphors; deep red and near-infrared phosphors select Y with emission peak wavelengths of 691nm and 708nm 3 (Al,Ga) 5 o 12 :Cr 3+ Phosphor; red phosphor chooses CaAlSiN with emission peak wavelength of 650nm 3 :Eu 2+ Phosphor. The mass ratio among the blue phosphor, the yellow-green phosphor, the near-infrared phosphor and the red phosphor is 60.4:15.5:20:4.1. The mass ratio of phosphor powder and packaging glue is 1:0.9. The packaging bracket is SMD type.

Embodiment 2

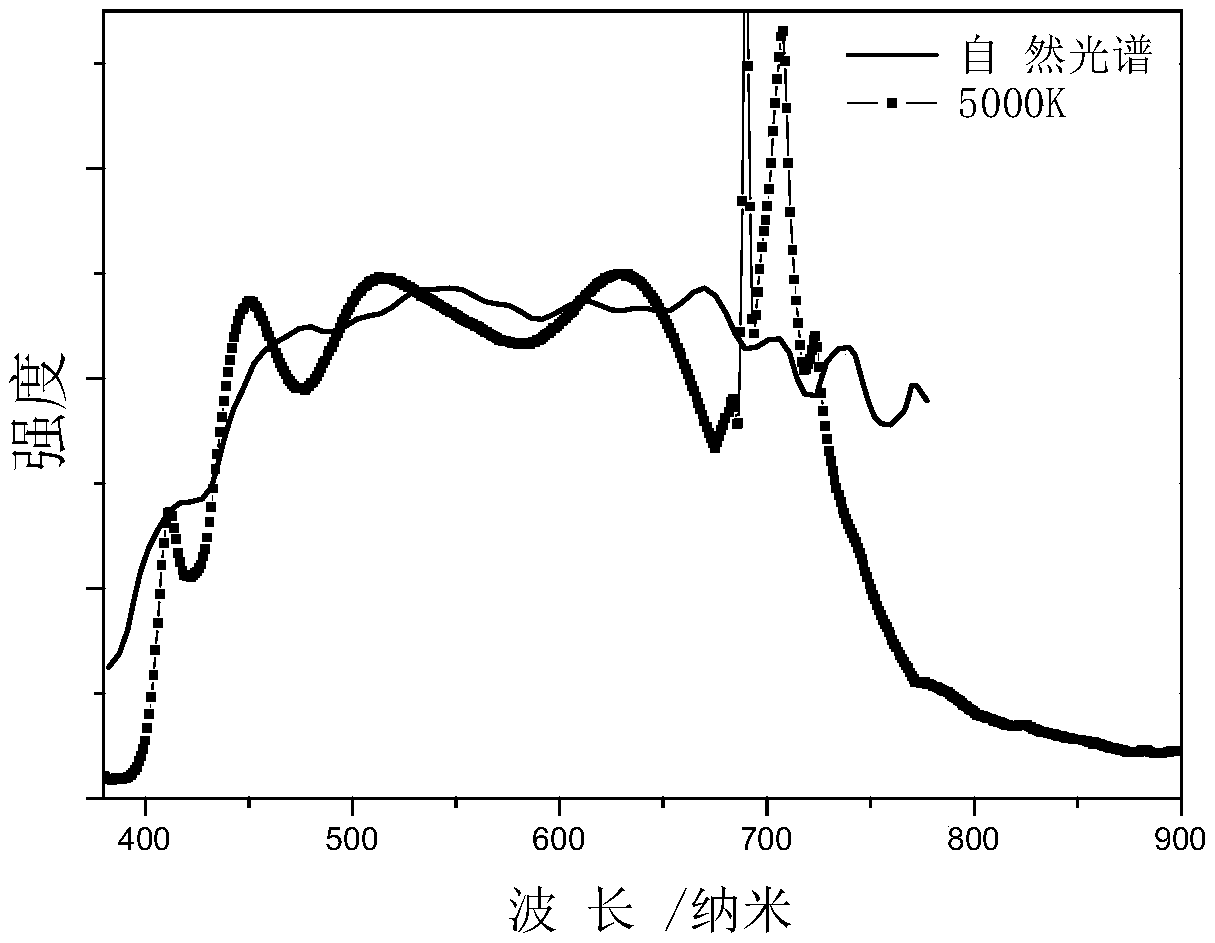

[0112] The LED chip chooses the purple LED chip with the emission peak wavelength of 410nm, the packaging glue chooses silicone resin, and the phosphor combination includes: the blue phosphor chooses the emission peak wavelength of 450nm (Sr, Ba) 5 (PO 4 )3 Cl:Eu 2+ Phosphor powder; yellow-green phosphor chooses Lu with emission peak wavelength of 535nm 3 Al 5 o 12 : Ce 3+ Phosphors; deep red and near-infrared phosphors select Y with emission peak wavelengths of 691nm and 710nm 3 (Al,Ga) 5 o 12 :Cr 3+ Phosphor; red phosphor chooses CaAlSiN with emission peak wavelength of 655nm 3 :Eu 2+ Phosphor. The mass ratio among the blue phosphor, the yellow-green phosphor, the near-infrared phosphor and the red phosphor is 58:18.5:20.1:3.4. The mass ratio of phosphor powder and packaging glue is 1:0.9. The packaging bracket is SMD type.

Embodiment 3

[0114] The LED chip chooses the purple LED chip with the emission peak wavelength of 420nm, the packaging glue chooses silicone resin, and the phosphor combination includes: the blue phosphor chooses the emission peak wavelength of 450nm (Sr, Ba) 5 (PO 4 ) 3 Cl:Eu 2+ Phosphor powder; yellow-green and deep red phosphors select Y with emission peak wavelengths of 530nm, 691nm and 708nm 3 (Al,Ga) 5 o 12 : Ce 3+ ,Cr 3+ Phosphor; red phosphor chooses CaAlSiN with emission peak wavelength of 655nm 3 :Eu 2+ Phosphor. The mass ratio among the blue phosphor, the yellow-green and near-infrared phosphor and the red phosphor is 73:22.4:4.6. The mass ratio of phosphor powder and packaging glue is 1:0.9. The packaging bracket is SMD type.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com