Automatic testing system for converter and usage thereof

An automatic test system and converter technology, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of wasting time, cumbersome data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

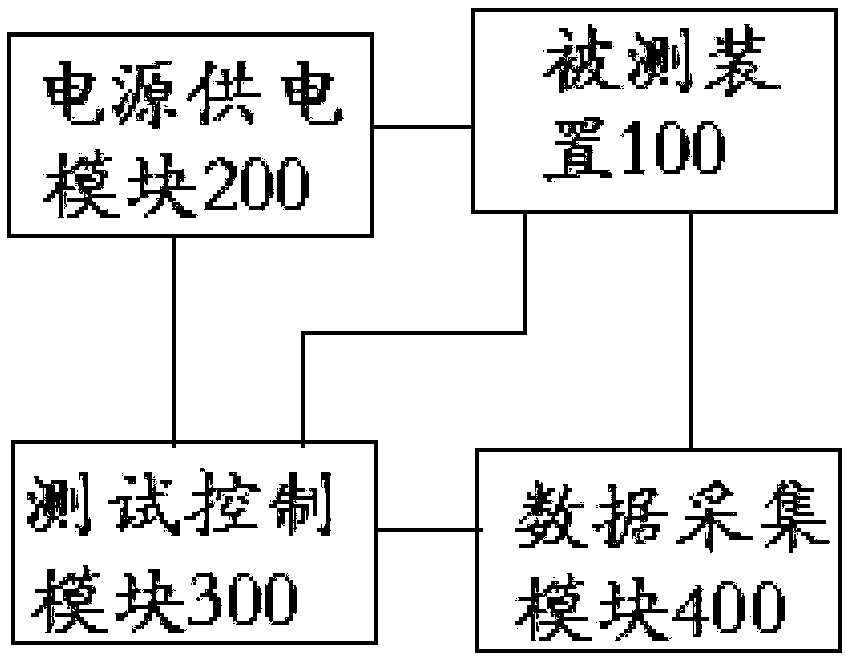

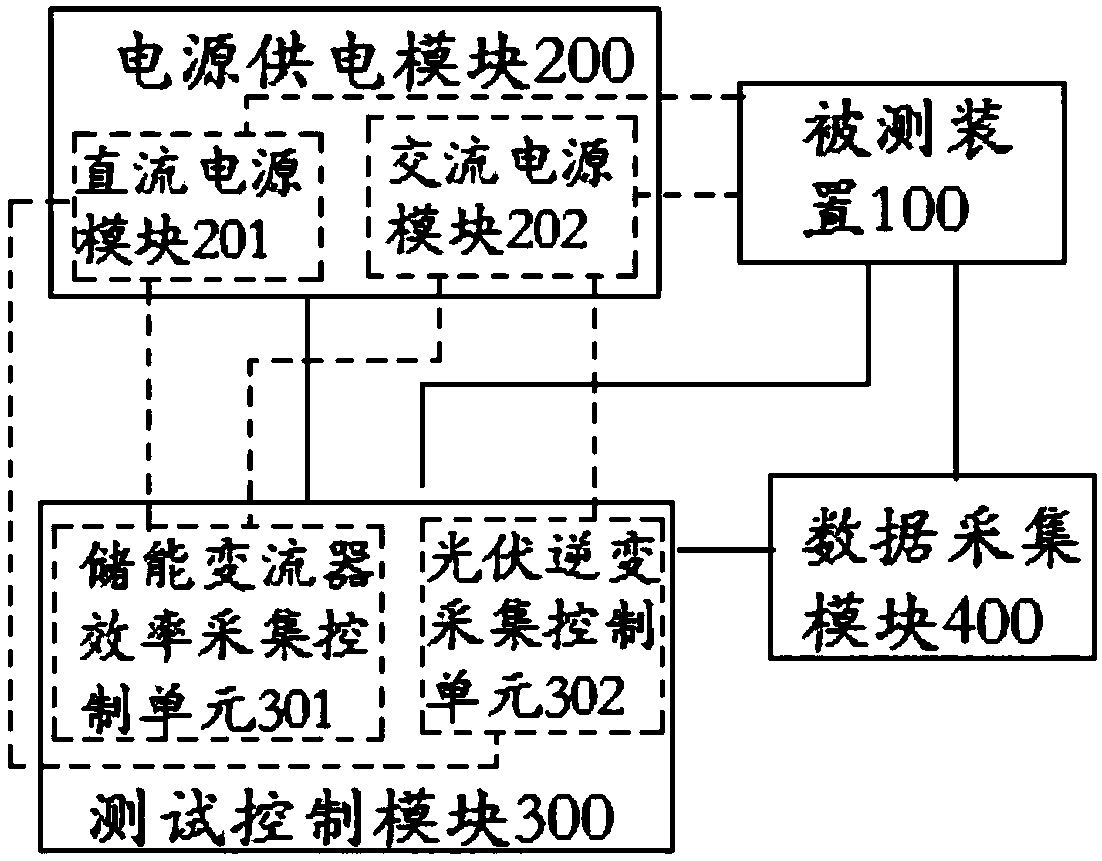

[0093] A converter automatic test system, such as figure 1 , 2 As shown, a power supply module 200 , a test control module 300 and a data acquisition module 400 for providing power to the device under test 100 are provided.

[0094] The test control module 300 is connected to the power supply module 200 , and the output terminal of the data acquisition module 400 is connected to the input terminal of the test control module 300 .

[0095] The specific working steps of the converter automatic test system are as follows;

[0096] S1: the test control module 300 outputs power supply parameter information to the power supply module 200;

[0097] S2: the power supply module 200 provides power to the device under test 100 according to the power supply parameter information;

[0098] S3: the data collection module 400 collects the parameters of the AC terminal and the DC terminal of the device under test 100 and generates a report;

[0099] S4: the data acquisition module 400 sen...

Embodiment 2

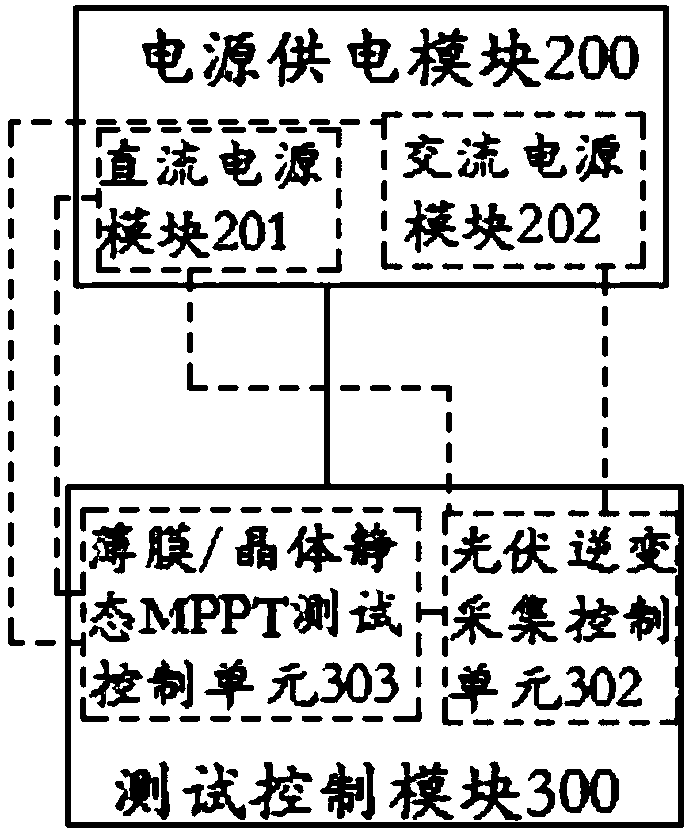

[0145] A converter automatic test system, other structures are the same as in Embodiment 1, the difference is that the converter automatic test system, specifically, the test control module 300 is also provided with a film / crystal static MPPT test control unit 303;

[0146] The film / crystal static MPPT test control unit 303 is respectively connected with the CV mode DC power supply 2011, the PV mode DC power supply 2012, the AC power supply module 202 and the photovoltaic inverter acquisition control unit 302;

[0147] The film / crystal static MPPT test control unit 303 controls the output power parameters 2011 of the CV mode DC power supply, the output power parameters of the PV mode DC power supply 2012, and the output power parameters of the AC power module 202, and sends them to the photovoltaic inverter acquisition control unit 302 for execution Step (2-1) - Operation of Step (2-7).

[0148] Specifically, the test steps of the film / crystal static MPPT test control unit 303...

Embodiment 3

[0159] A converter automatic test system, other structures are the same as those in Embodiment 1 or 2, the difference is that the test control module 300 is also provided with a photovoltaic inverter harmonic test control unit 304; the photovoltaic inverter acquisition control unit 302 is respectively Connect with the DC power supply module 201, the AC power supply module 202 and the data acquisition module 400;

[0160] Specifically, the photovoltaic inverter harmonic test control unit 304 controls the power output parameters of the DC power module 201 and the output parameters of the AC power module 202 and sends them to the data acquisition module 400 .

[0161] Specifically, the control steps of the photovoltaic inverter harmonic test control unit 304 are as follows:

[0162] Step (4-1) setting the DC power supply CV mode;

[0163] Step (4-2) setting the voltage of the AC power supply to V4, the frequency to F4 and the phase to Φ4;

[0164] Specifically, as mentioned abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com