Automatic crawling helium leakage detection system for heat-exchanging tube and caulk weld in heat exchanger tube plate

A heat exchanger tube and automatic crawling technology, applied in the field of automatic air tightness detection, can solve the problems of affecting the detection results and high labor intensity of detection personnel, so as to ensure consistency and accuracy, facilitate promotion and use, and save manpower and physical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

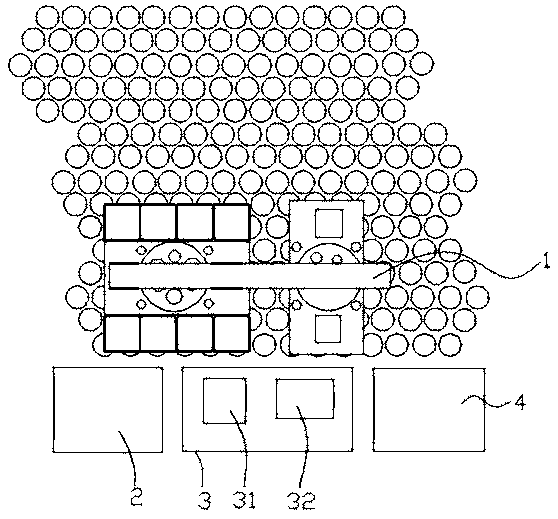

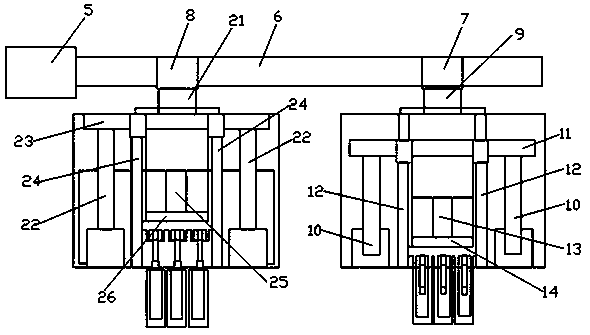

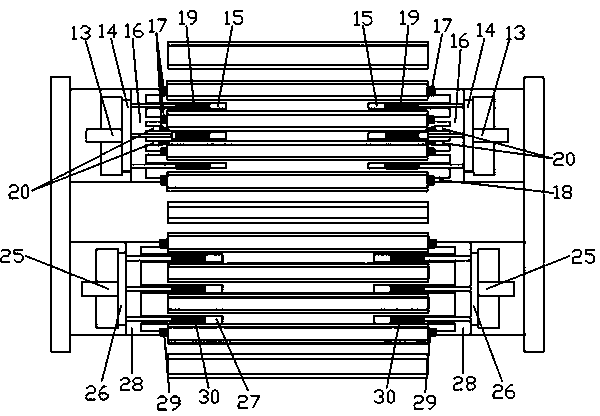

[0021] In this application, move the sealing front-end device 1. After one end of the front-end device moves to a predetermined position, the cylinder of the vertical tube plate in the device is activated, and the "core" is inserted into the tube hole. After the detection is completed, the cylinder lifts it out of the tube. board to move to the next position. PLC front-end control unit 2: used to control the action of the mobile sealing fixture device and the vacuum system. Vacuum leak detection device 3: Refers to the leak detector and related vacuum pipe fittings. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com