Stainless steel sealing tube joint

A technology of stainless steel pipe and sealing pipe, applied in the direction of pipe/pipe joint/pipe fitting, sleeve/socket connection, passing element, etc., can solve the problem of poor sealing effect at the joint between pipe joint and stainless steel pipe, and achieves a clear principle, The effect of increasing the sealing range and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

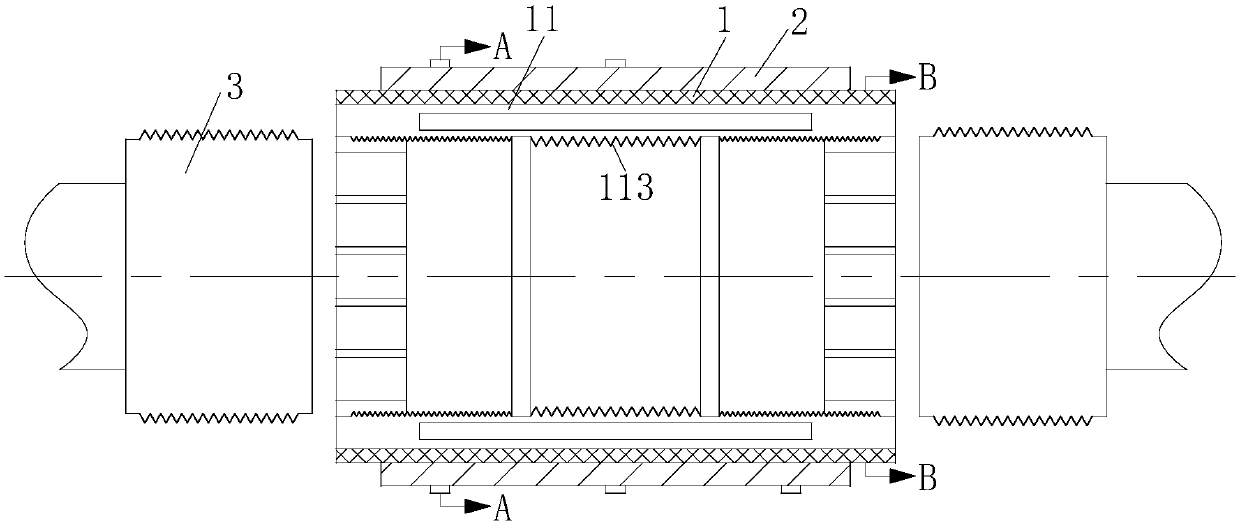

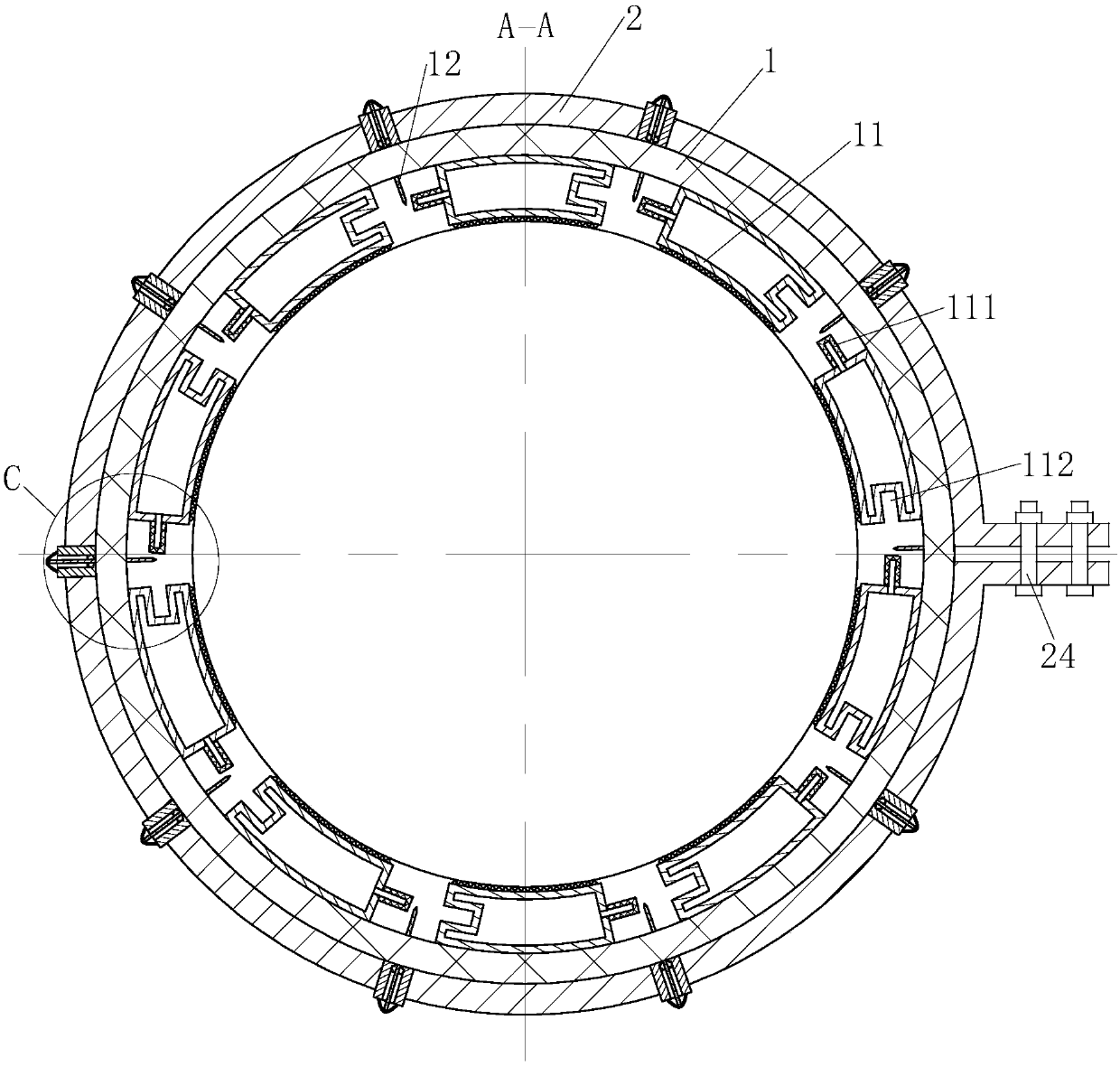

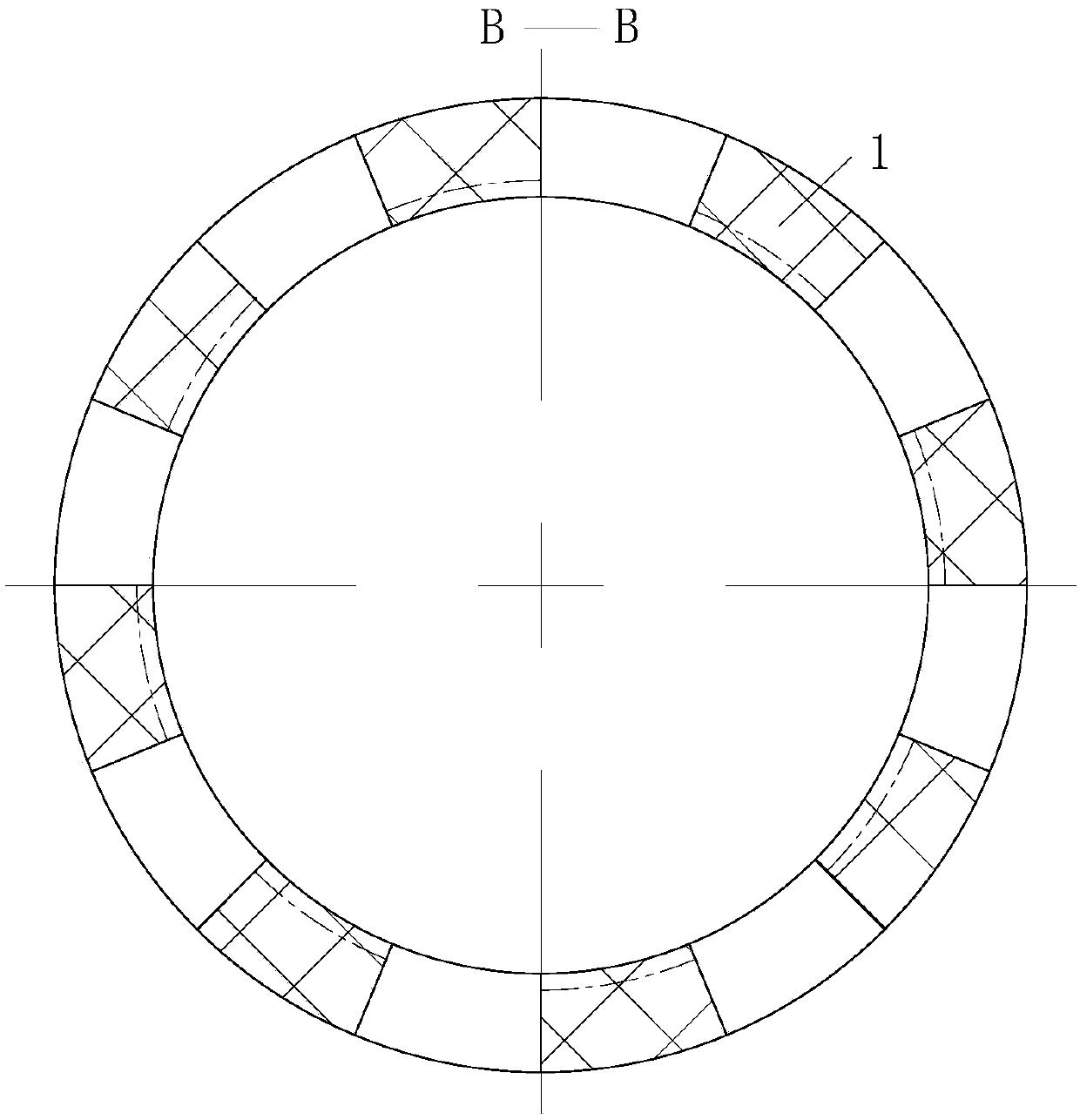

[0023] use Figure 1 to Figure 5 A stainless steel sealing pipe joint of the present invention is described as follows.

[0024] Such as Figure 1 to Figure 5 As shown, a stainless steel sealed pipe joint according to the present invention includes a joint body 1 and a stainless steel pipe 3; threads are provided on the outer wall of the stainless steel pipe 3; the joint body 1 is a rubber tube, and the two ends of the joint body 1 There is a No. 1 thread on the inner wall of the end, and the two ends of the joint body 1 are expandable. The middle part of the inner wall of the joint body 1 is provided with a No. 2 thread 113, and the thread diameter of the No. 2 thread 113 is larger than that of the No. 1 thread. The joint body 1 can adapt to two kinds of stainless steel pipes 3 with different diameters through the No. 1 thread and No. 2 thread 113; the outer wall of the joint body 1 is provided with a clamp 2; The joint body 1 and the stainless steel pipe 3 that fit togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com