Engine crankshaft signal disc abrasion detection method and device and electronic control unit

A signal plate and engine technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as unstable engine speed, traveling car, and no synchronous signal of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

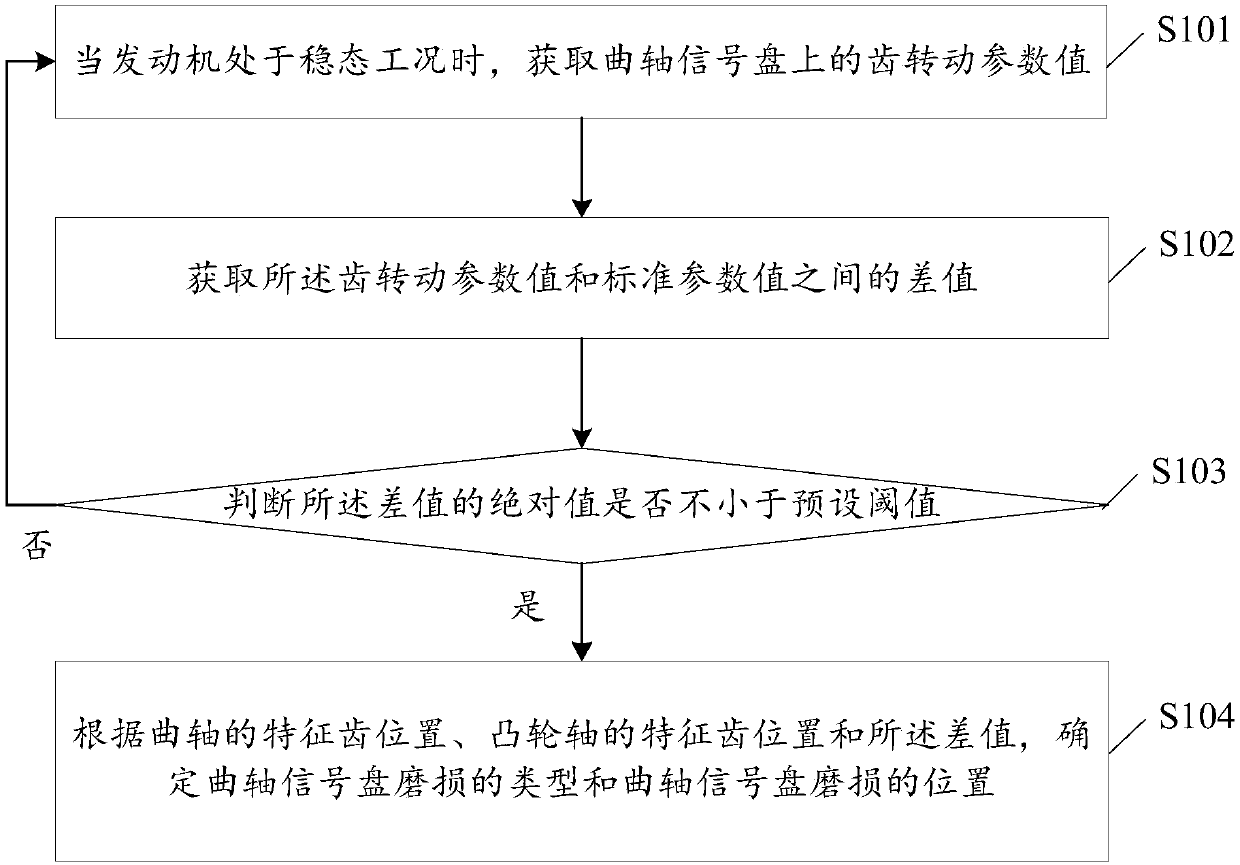

[0066] see figure 1 , which is a flow chart of an implementation of a method for detecting wear of an engine crankshaft signal disc provided in an embodiment of the present application.

[0067] The detection method of the engine crankshaft signal plate wear provided by the embodiment of the present application includes:

[0068] S101: When the engine is in a steady state condition, obtain the tooth rotation parameter value on the crankshaft signal plate.

[0069] Steady state condition means that the engine is in a steady state. Whether the engine is in a steady-state condition can be determined based on various engine parameters.

[0070] As an example, whether the engine is in a steady-state operating condition may be determined according to whether the rotational speed of the engine is stable. If the rotational speed of the engine is stable, it means that the engine is in a steady state; if the rotational speed of the engine is unstable, it means that the engine is not ...

Embodiment 2

[0138] Embodiment 2 is an improvement made on the basis of Embodiment 1. For the sake of brevity, the parts of Embodiment 2 and Embodiment 1 that have the same content will not be repeated here.

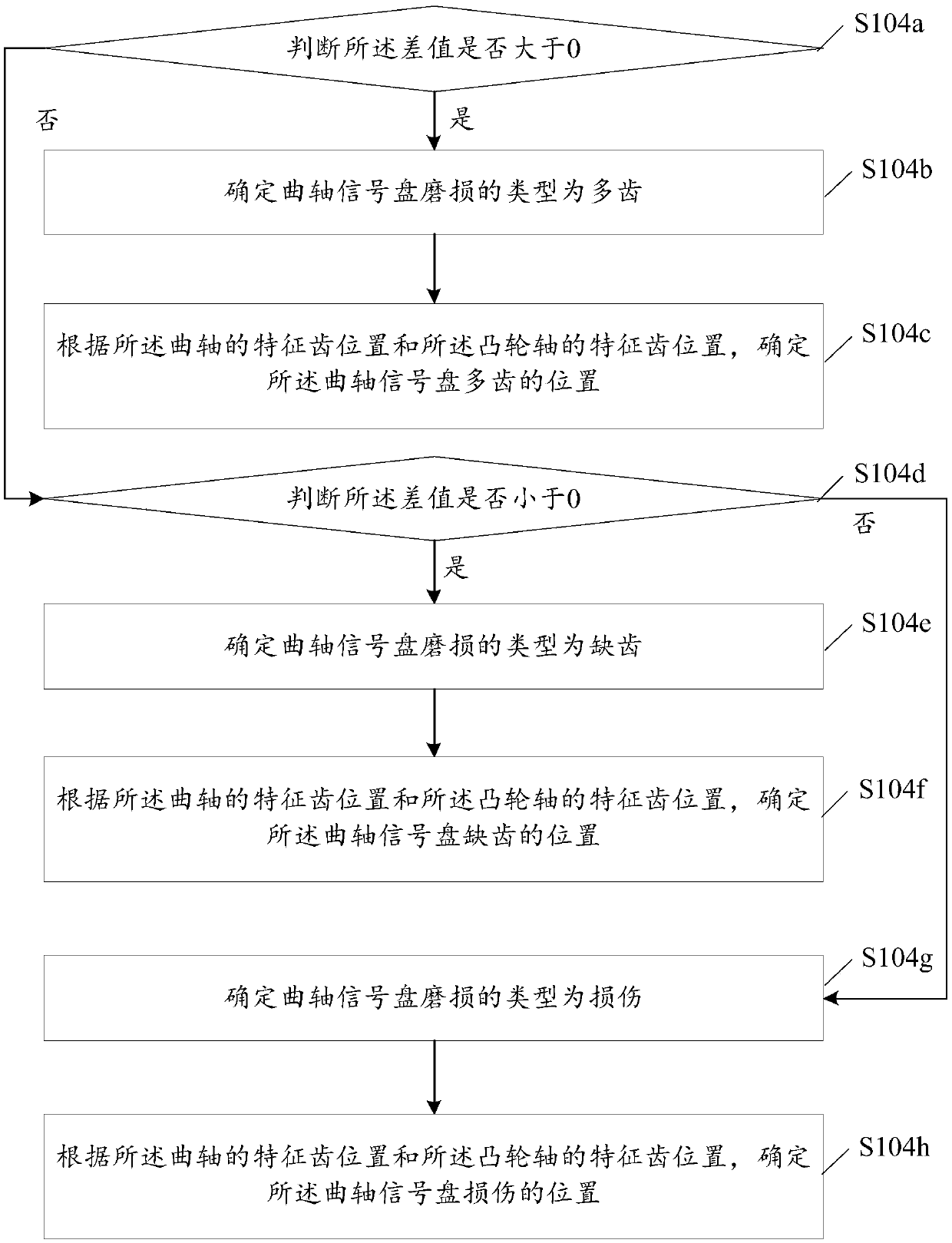

[0139] see Figure 5 , which is a flow chart of another implementation of the method for detecting the wear of the engine crankshaft signal disc provided in the embodiment of the present application.

[0140] The detection method of the engine crankshaft signal plate wear provided by the embodiment of the present application includes:

[0141] S201: Determine whether the engine is in a steady state. If yes, execute S202; if not, execute S201.

[0142] If the engine is not in a steady state condition, the obtained crankshaft signal plate tooth rotation parameter value is inaccurate, reducing the accuracy of determining the type of crankshaft signal plate wear and the location of the crankshaft signal plate wear. Thus, to improve the accuracy of determining the type of crankshaft si...

Embodiment approach

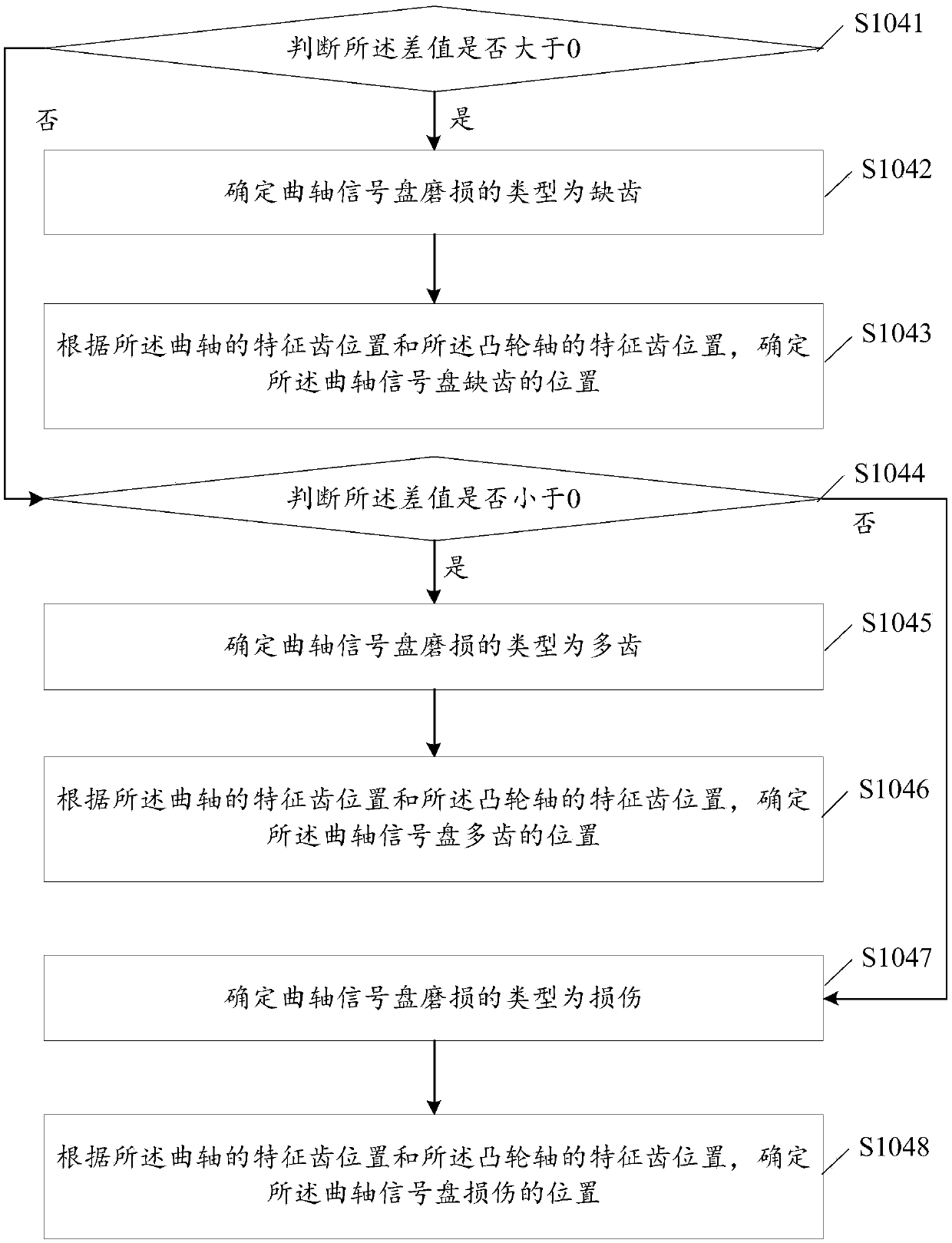

[0174] As another implementation, the tooth rotation parameter value is the number of tooth periods; the tooth period is the time interval between two adjacent teeth on the crankshaft signal plate;

[0175] The first determination module 604 specifically includes:

[0176] The second judging submodule is used to judge whether the difference is greater than 0;

[0177] The third determining submodule is used to determine that the type of crankshaft signal disc wear is multi-tooth if the difference is greater than 0, and determine the The multi-tooth position of the crankshaft signal plate;

[0178] The fourth determining submodule is used to determine that the type of crankshaft signal plate wear is missing teeth if the difference is less than 0, and determine the The location of the missing tooth on the crankshaft signal plate.

[0179] As yet another implementation, the value of the tooth rotation parameter is the circumference of the tooth; wherein, the circumference of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com