Convenient operation platform for hoisting assembly-type girder

An operating platform and convenient technology, which is applied to the accessories of scaffolding, the scaffolding supported by the building structure, the support of the building structure, etc., can solve the problems of unfavorable management, disordered material stacking, messy site, etc., and save labor and turnover materials. , the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

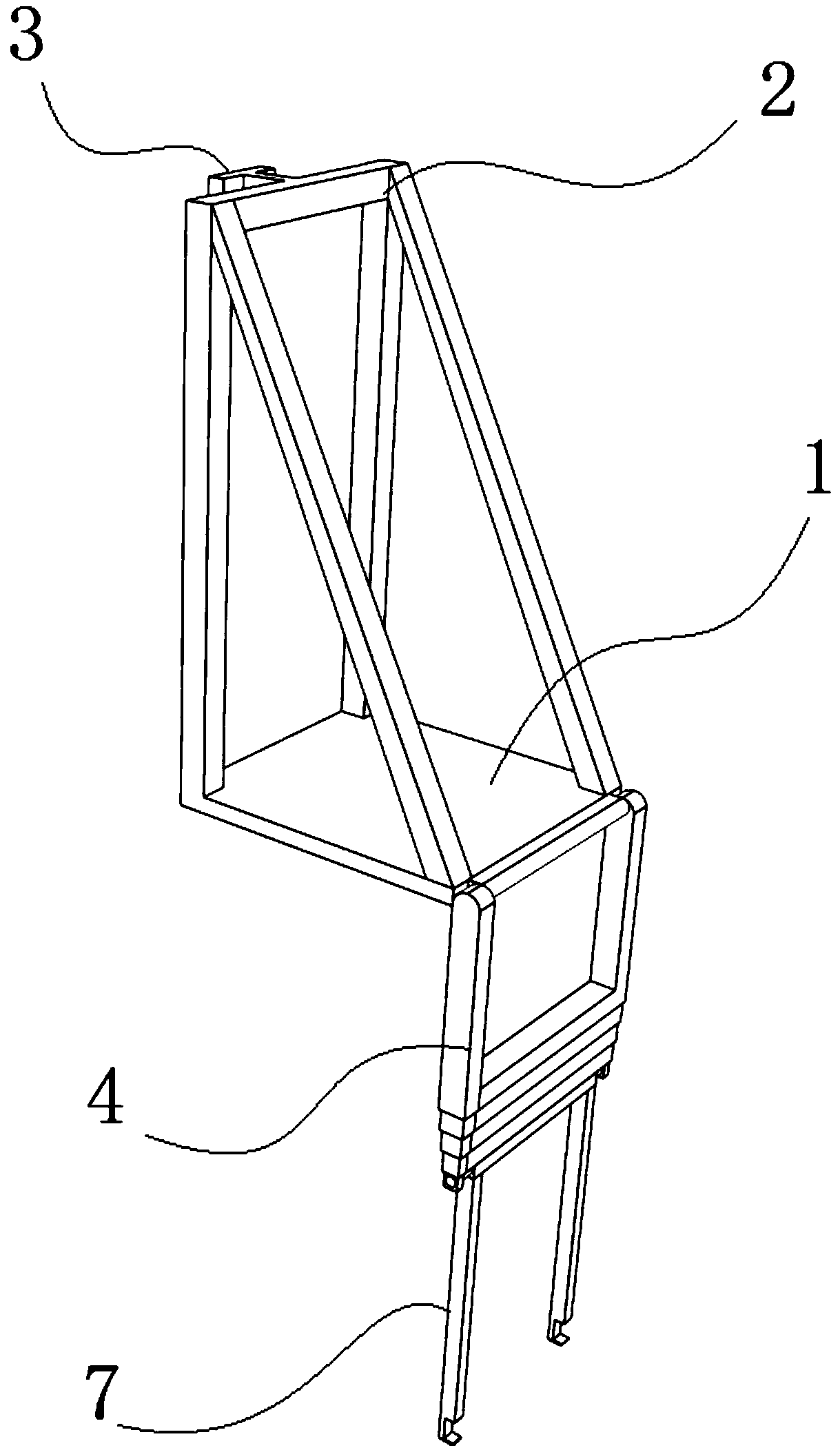

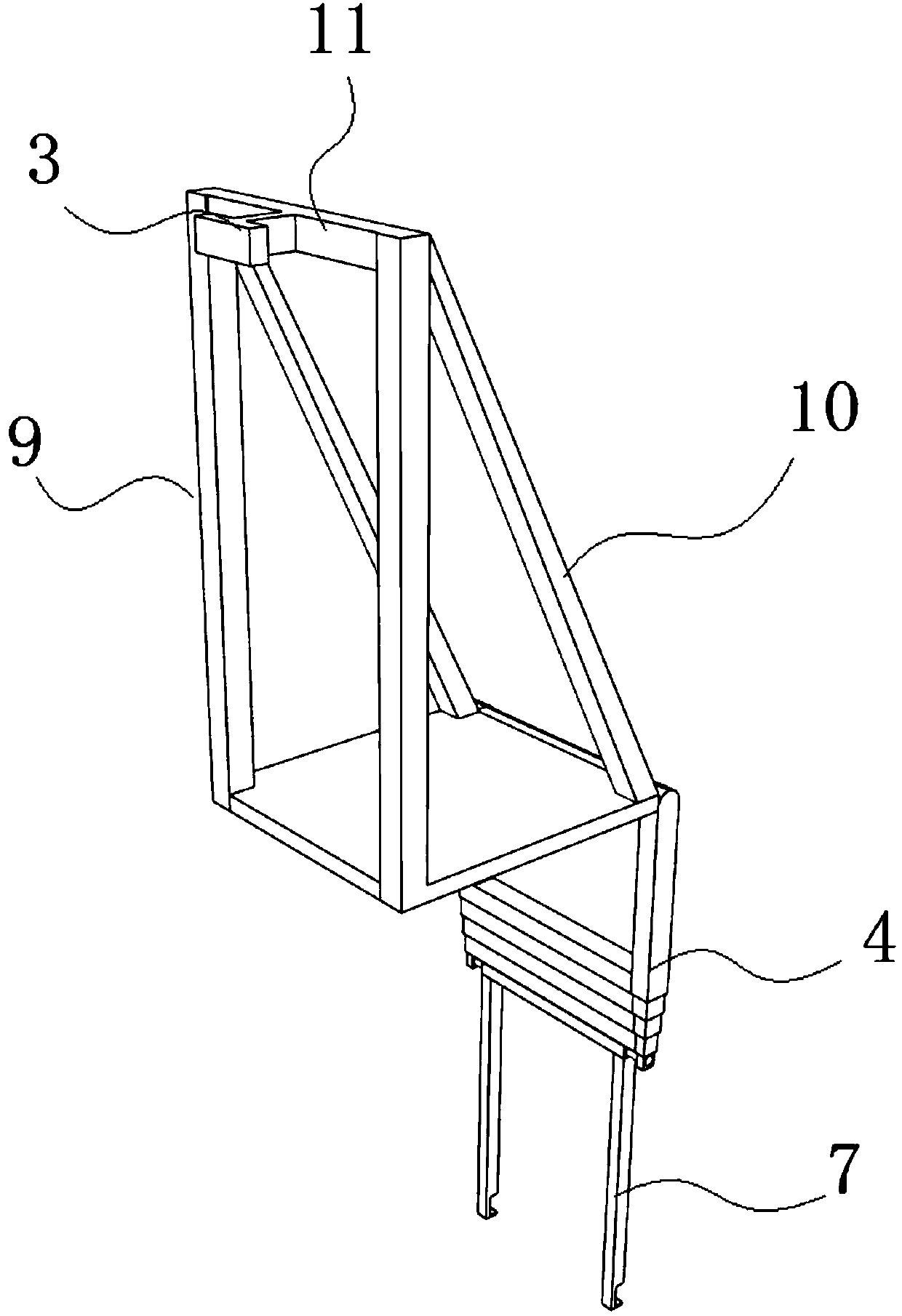

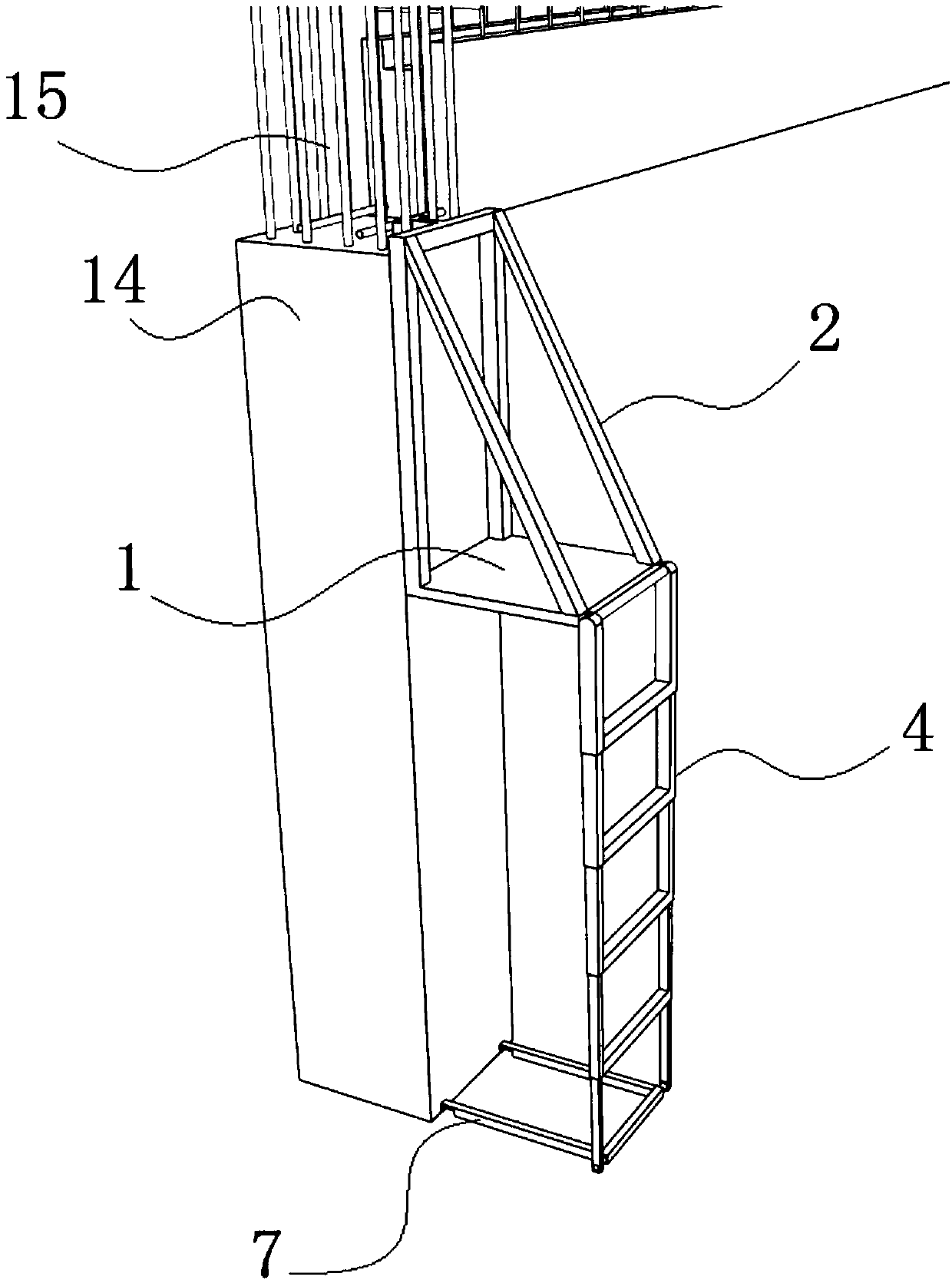

[0025] Example: such as Figure 1~3 As shown in the figure, a portable operation platform for hoisting of the assembled main girder includes an operation platform 1 located at the bottom of the operation platform. The four corners of the platform 1 are installed with side rails 2 extending upwards. The side rails 2 can withstand the hoisting tension of the suspension and support the work platform 1. The fixing device 3 is made of section steel, and is used to fix the clamping position on the steel bar 15 above the prefabricated column 14, and fix the clamping position with the steel bar 15 to realize the fixed force; the fixing device installed on the working platform 1 relative to the clamping position The telescopic staircase 4 on the bottom edge of one side is used for operators to climb to the work platform 1, and the top of the telescopic staircase 4 is inserted into the bottom edge of the work platform 1 through the first rotating shaft 5, so that the telescopic staircas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com