Conveying device of tufting embroidering machine

A velvet embroidery machine and embroidery machine technology, which is applied in the field of tufted embroidery machines, can solve the problems of unguaranteed quality, high labor cost, and low efficiency of manual feeding, so as to ensure the uniformity and stability of tension, reduce labor costs, The effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

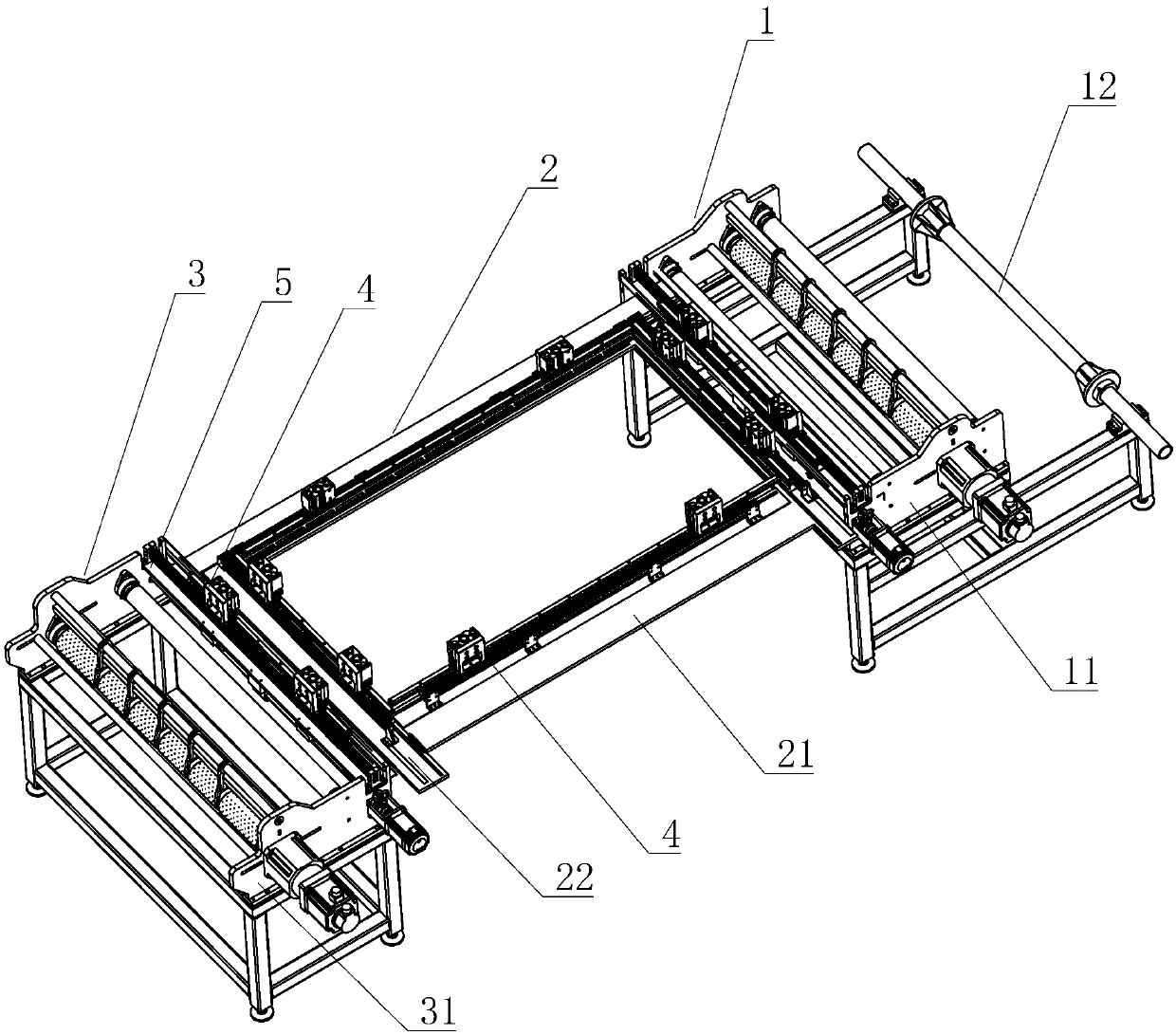

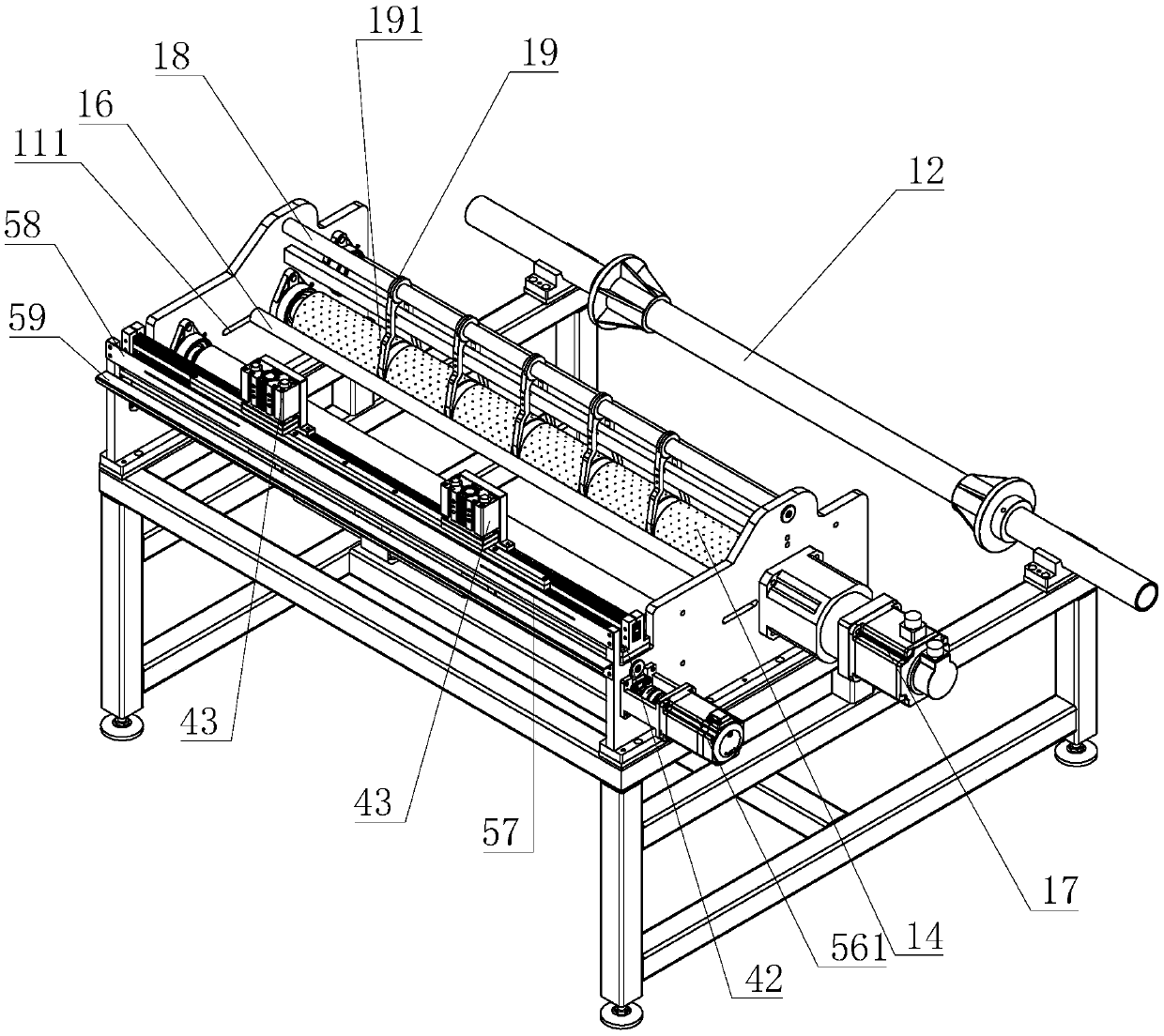

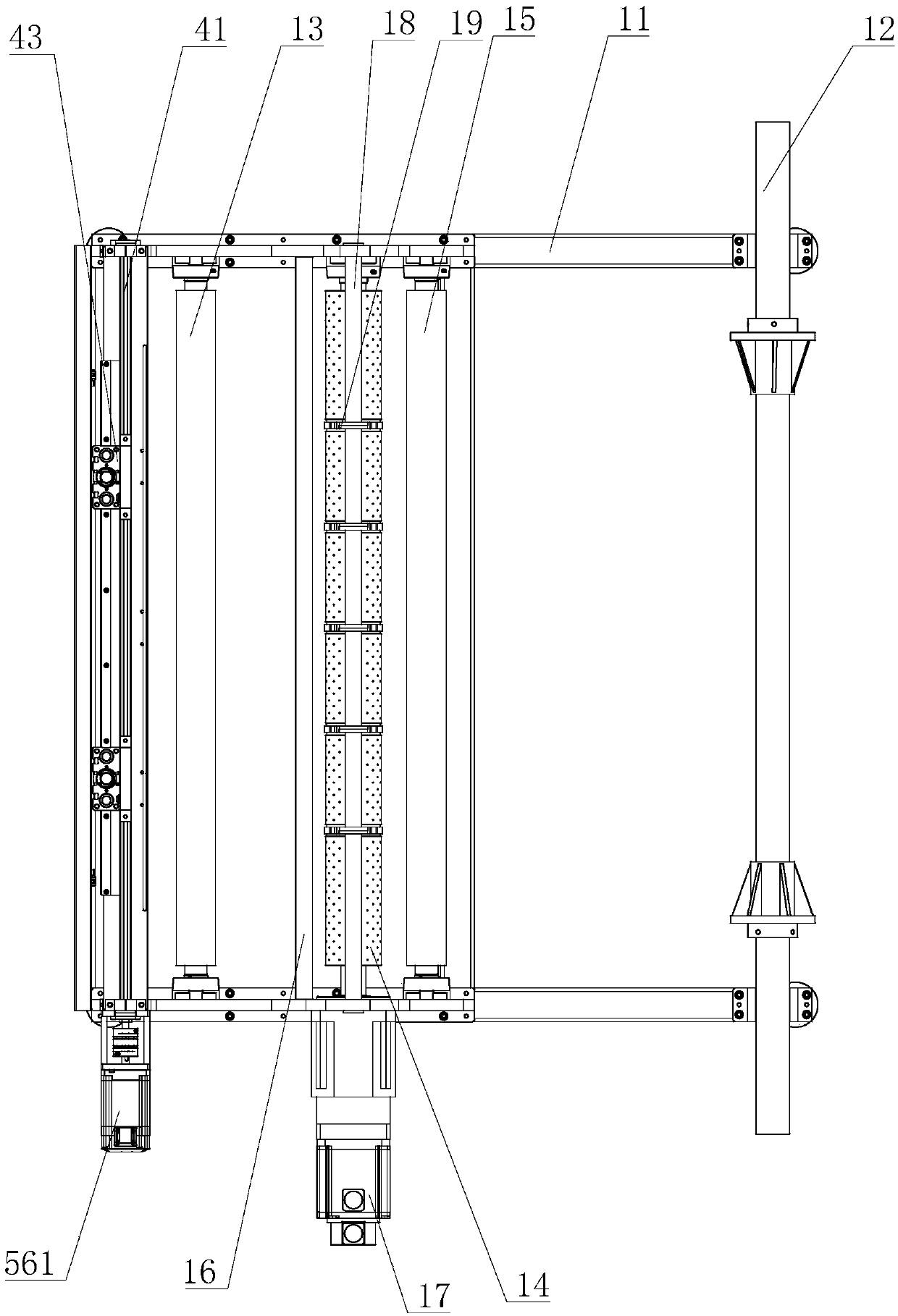

[0027] Embodiment one, see Figure 1-8 , the present embodiment discloses a feeding device for a tufted embroidery machine, which includes a feeding part 1, a positioning part 2 and a receiving part 3 connected in sequence according to the traveling direction of the cloth, and the feeding part 1 is used to transfer the blanket base cloth to the tufting Waiting for embroidery under the embroidery machine, the positioning part 2 is located under the embroidery device of the tufting embroidery machine to fix the tensioned blanket base fabric, the receiving part 3 is used to collect the embroidered blanket, and the feeding part 1 includes the feeding frame 11. The feeding frame 11 is fixedly installed on the ground through metal feet, the receiving part 3 includes a receiving frame 31, and the receiving frame 31 is fixedly installed on the ground through metal feet, and the positioning part 2 includes two wefts arranged in parallel. To base plate 22 and two warp base plates 21 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com