High-precision stitching-breakage-prevention papermaking blanket production method and needling machine thereof

A technology of paper-making felt and production method, which is applied in the textile field, can solve problems such as stacking, broken needle accidents, poor matching, etc., and achieve the effects of improving stability and continuity, improving stability and reliability, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

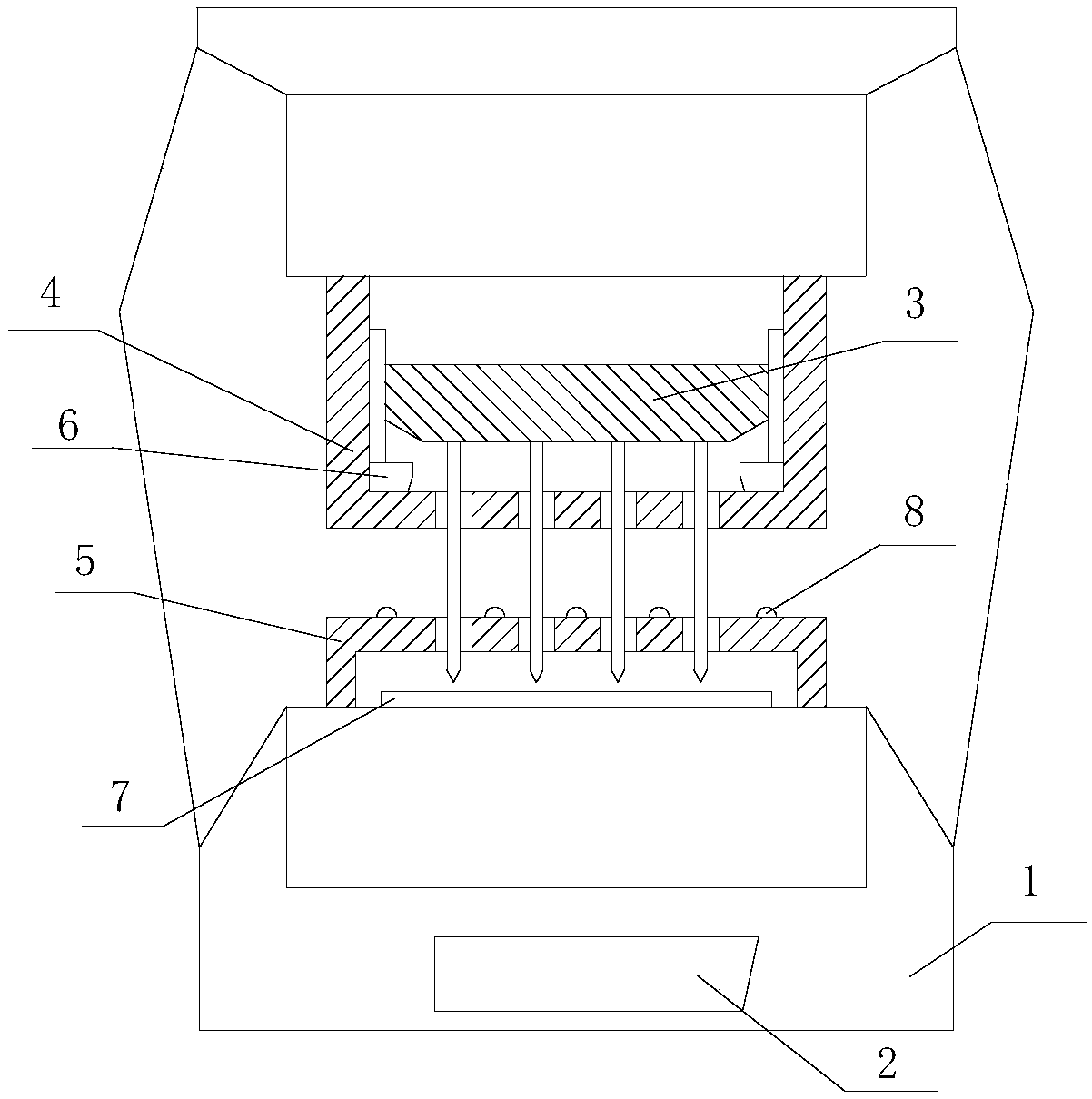

[0025] Such as figure 1 Shown, a kind of high-precision anti-broken papermaking felt production method comprises the following steps:

[0026] S1, knitting plan preset, first enter the width, thickness, length and fiber weaving plan of the papermaking felt to be processed into the control system of the knitting machine, and then generate knitting machine needles according to the entered width, thickness, length and fiber weaving plan Needle movement track parameters, speed, depth, pressure parameters, knitting machine electric control system operating speed parameters and needle movement and knitting machine electric control advance parameters, and finally set the surface tension parameters during the papermaking blanket knitting operation during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com