Improvement method for novel paper making felt needling machine

A technology for paper-making blankets and needle looms, which is applied in the fields of needle looms, textiles, papermaking, and non-woven fabrics, and can solve the problem of increasing the labor cost of knitting machine equipment transformation and maintenance operations, affecting the stability of knitting machine equipment and product production quality , Insufficient stability of knitting machine equipment and other problems, to achieve the effect of low cost of transformation, improvement of stability and continuity, and improvement of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

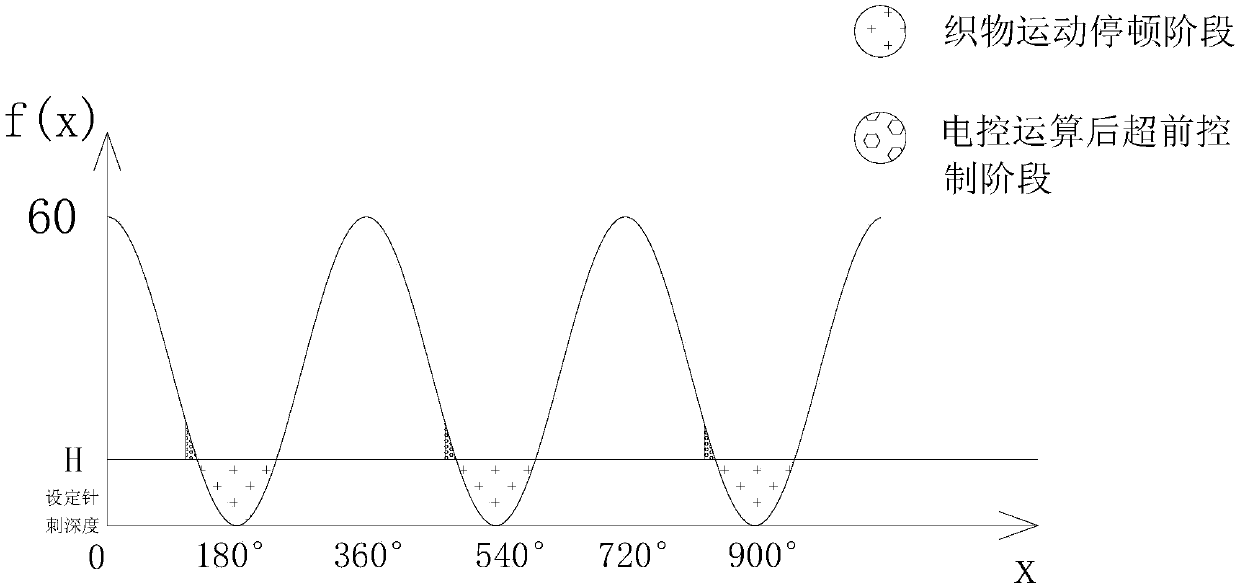

[0025] Such as figure 1 As shown, an improved method of a novel papermaking felt needle loom, comprising the following steps:

[0026] S1, parameter statistics, firstly set the operating parameters of the knitting machine to be modified after modification, then collect the mechanical and driving mechanism parameters and electrical control system parameter information of the current knitting machine to be modified, and finally modify the collected parameter information and settings After the operation parameters are compared, the corresponding components of the current knitting machine equipment to be transformed that cannot meet the modified operation parameters among the mechanical and drive mechanism parameters and electrical control system para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com