Novel auxiliary frame installing bush

A sub-frame, a new type of technology, applied in the direction of vehicle components, transportation and packaging, substructure, etc., can solve the problems affecting the longitudinal comfort of the vehicle, poor cushioning effect, etc., achieve good economic and social benefits, save costs, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

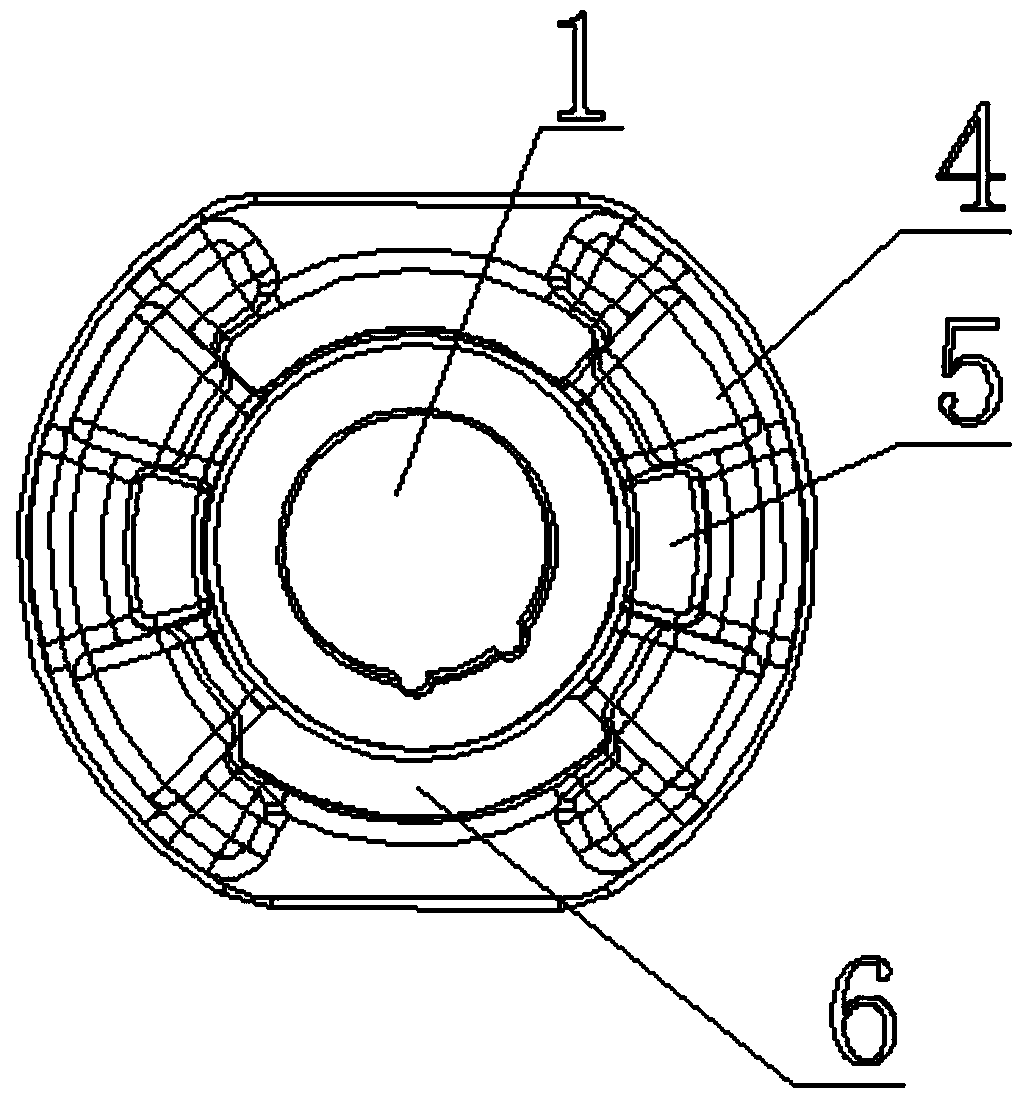

[0019] Example: such as Figure 1-3 As shown, the present invention provides a new type of auxiliary frame mounting bushing, which includes an inner sleeve 1, a rubber buffer structure 2 and an outer sleeve 3, the inner sleeve 1 is provided with a rubber buffer structure 2, and the inner sleeve 1 1. An outer sleeve 3 is sheathed on the outside. A top buffer block 4 is provided on one side of the inner sleeve 1. A lateral slot 5 is provided on one side of the top buffer block 4. A lateral slot 5 is provided on one side of the lateral slot 5. A longitudinal hole 6 is provided, and a bottom buffer block 7 is provided at the bottom of the inner casing 1 .

[0020] In order to make the bushing installed on the new sub-frame easy to use and high in work efficiency, the inner sleeve 1 is vulcanized with the rubber buffer structure 2, and the rubber buffer structure 2 is vulcanized with the outer sleeve 3. The outer sleeve 3 and the sub-frame sleeve are interference-fitted, the mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com