Environment-friendly printing technology

A process and environmental protection technology, applied in the direction of printing, printing surface preparation, printing device, etc., can solve the problems that cannot meet various types of daily production, unfavorable and other problems, achieve easy edge effect, control edge effect, and avoid ink denaturation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

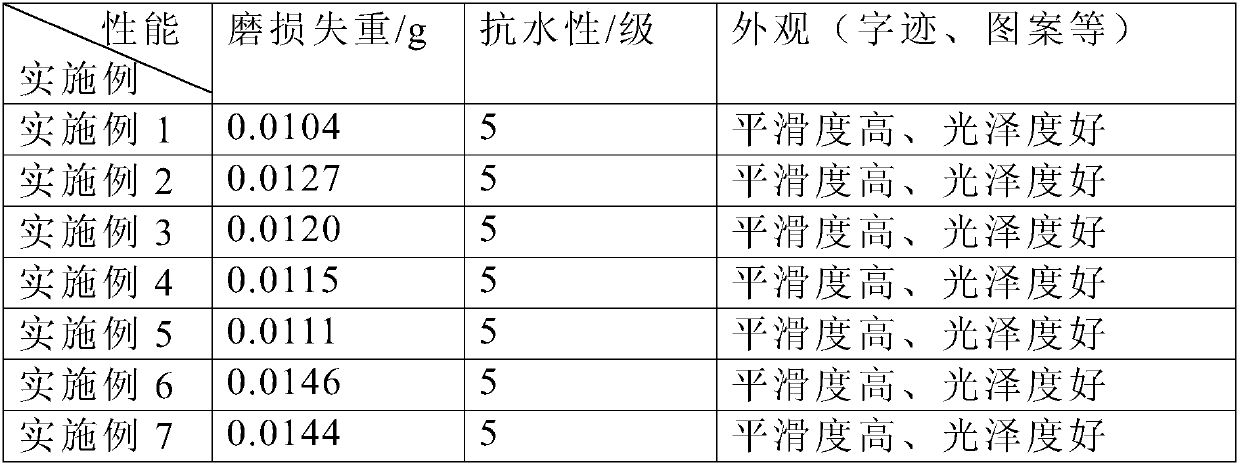

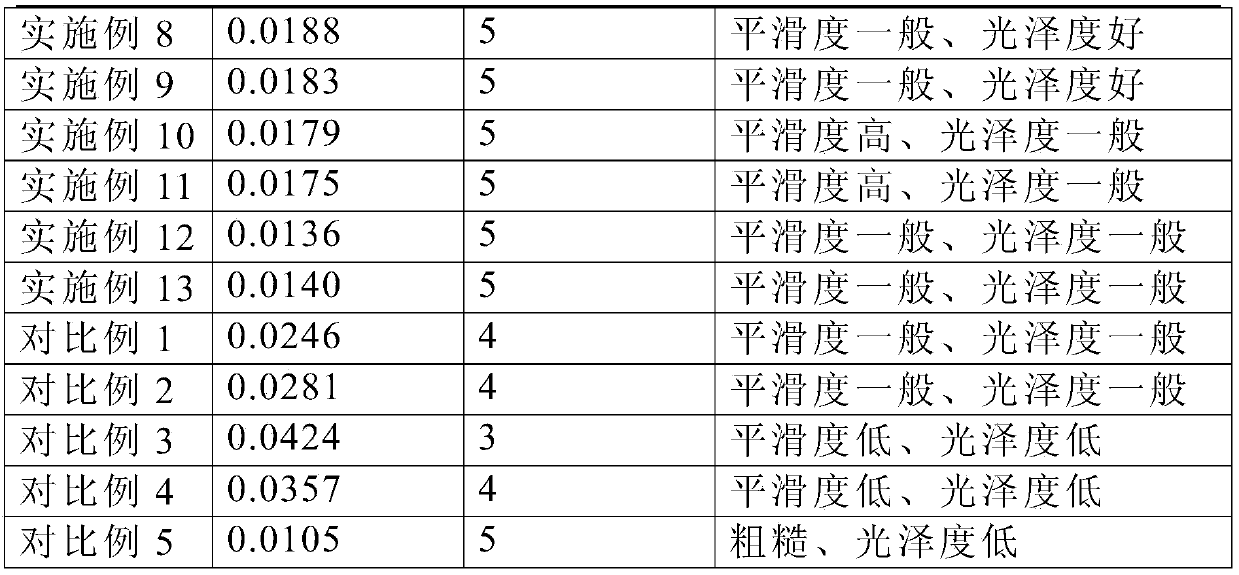

Examples

Embodiment 1

[0027] According to the specifications of the printed matter, the printing plates are processed by issuing, proofing, imposing, and printing;

[0028] The dampening treatment of the printing plate adopts alcohol-free dampening solution, and the dampening solution includes the following components in parts by weight: 30 parts of oxalic acid, 4 parts of zinc chloride, 15 parts of peach gum, 3 parts of red agate powder, octylphenol 5 parts of polyoxyethylene ether, 8 parts of auxiliary additives, wherein the particle diameter of onyx powder is 400nm, then fix on the printer, and the composite ink is poured into the printer, wherein the composite ink includes the following components in parts by weight: pigment 7 parts, 40 parts of episulfide resin, 4 parts of ethyl acetate, 5 parts of dicyandiamide, 6 parts of glyceryl oleate, 2 parts of oxalic acid, 3 parts of magnesium sulfate, 5 parts of protein powder, 4 parts of beeswax, 25 parts of auxiliary agent 3 parts, 3 parts of disper...

Embodiment 2

[0031] According to the specifications of the printed matter, the printing plates are processed by issuing, proofing, imposing, and printing;

[0032] The dampening treatment of the printing plate adopts alcohol-free dampening solution, and the dampening solution includes the following components in parts by weight: 20 parts of oxalic acid, 3 parts of zinc chloride, 10 parts of peach gum, 2 parts of red agate powder, octylphenol 4 parts of polyoxyethylene ethers, 5 parts of auxiliary additives, wherein the particle diameter of onyx powder is 200nm, then fix on the printer, and the composite ink is poured into the printer, wherein the composite ink includes the following components in parts by weight: pigment 7 parts, 40 parts of episulfide resin, 4 parts of ethyl acetate, 5 parts of dicyandiamide, 6 parts of glyceryl oleate, 2 parts of oxalic acid, 3 parts of magnesium sulfate, 5 parts of protein powder, 4 parts of beeswax, 25 parts of auxiliary agent 3 parts, 3 parts of dispe...

Embodiment 3

[0035] According to the specifications of the printed matter, the printing plates are processed by issuing, proofing, imposing, and printing;

[0036] The dampening treatment of the printing plate adopts alcohol-free dampening solution, and the dampening solution includes the following components in parts by weight: 40 parts of oxalic acid, 5 parts of zinc chloride, 20 parts of peach gum, 4 parts of red agate powder, octylphenol 6 parts of polyoxyethylene ether, 10 parts of auxiliary additives, wherein the particle diameter of onyx powder is 600nm, then fix on the printer, and the composite ink is poured into the printer, wherein the composite ink includes the following components in parts by weight: pigment 7 parts, 40 parts of episulfide resin, 4 parts of ethyl acetate, 5 parts of dicyandiamide, 6 parts of glyceryl oleate, 2 parts of oxalic acid, 3 parts of magnesium sulfate, 5 parts of protein powder, 4 parts of beeswax, 25 parts of auxiliary agent 3 parts, 3 parts of dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com