A resistance welding machine control device

A resistance welding machine and control device technology, applied in the direction of resistance welding equipment, resistance electrode base, manufacturing tools, etc., can solve the problems that the resistance welding machine is easy to shake, easy to hit the staff, and hurt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described with reference to the accompanying drawings.

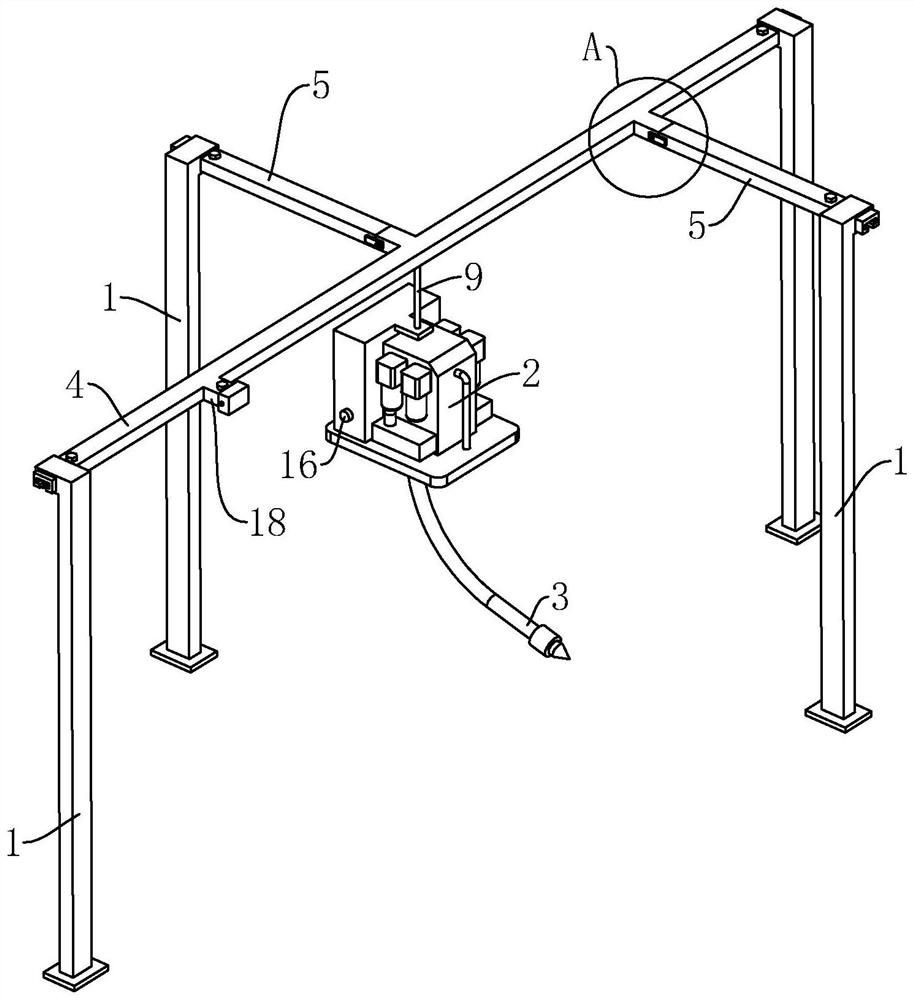

[0032] A resistance welding machine control device, such as figure 1 As shown: it includes a bracket 1 and a substrate 2 arranged on the bracket 1 , and a welding head 3 is arranged on the substrate 2 .

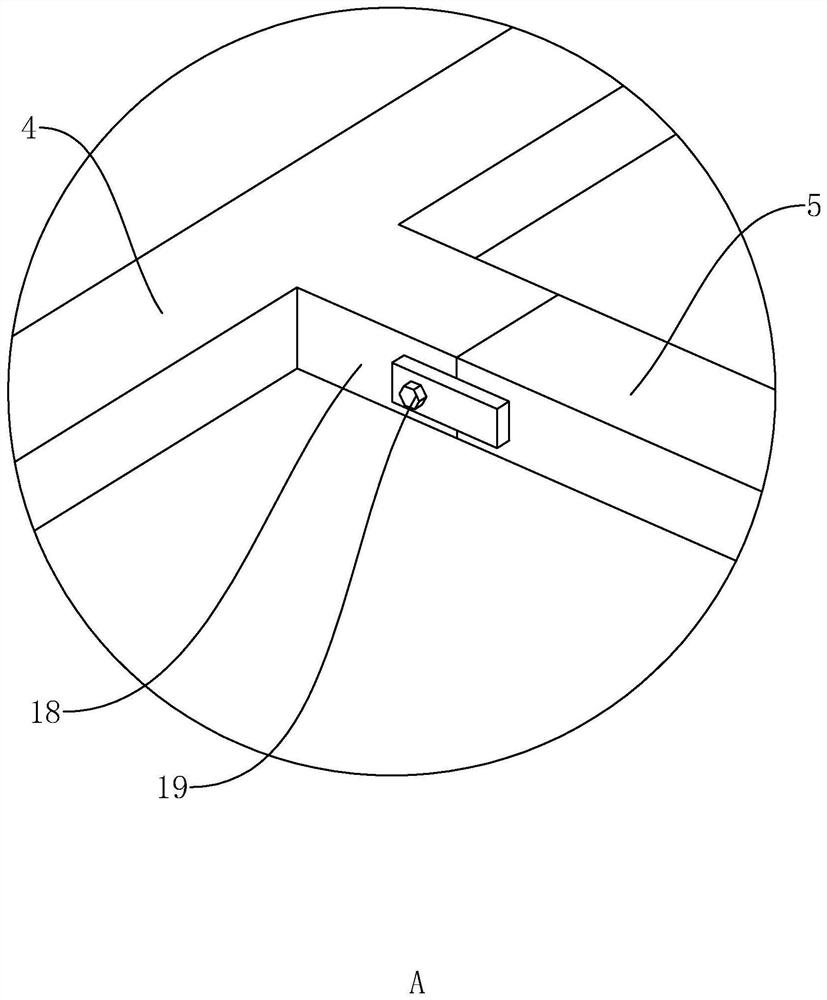

[0033] Such as figure 1 and 2 As shown: a guide rail 4 is arranged on the bracket 1, and a plurality of connecting rails 18 are arranged on the side of the guide rail 4, and the connecting rails 18 are perpendicular to the extending direction of the guide rail 4. The connecting rail 18 is provided with an extension rail 5 . The extension rail 5 is connected with the connecting rail 18 by bolts 19 .

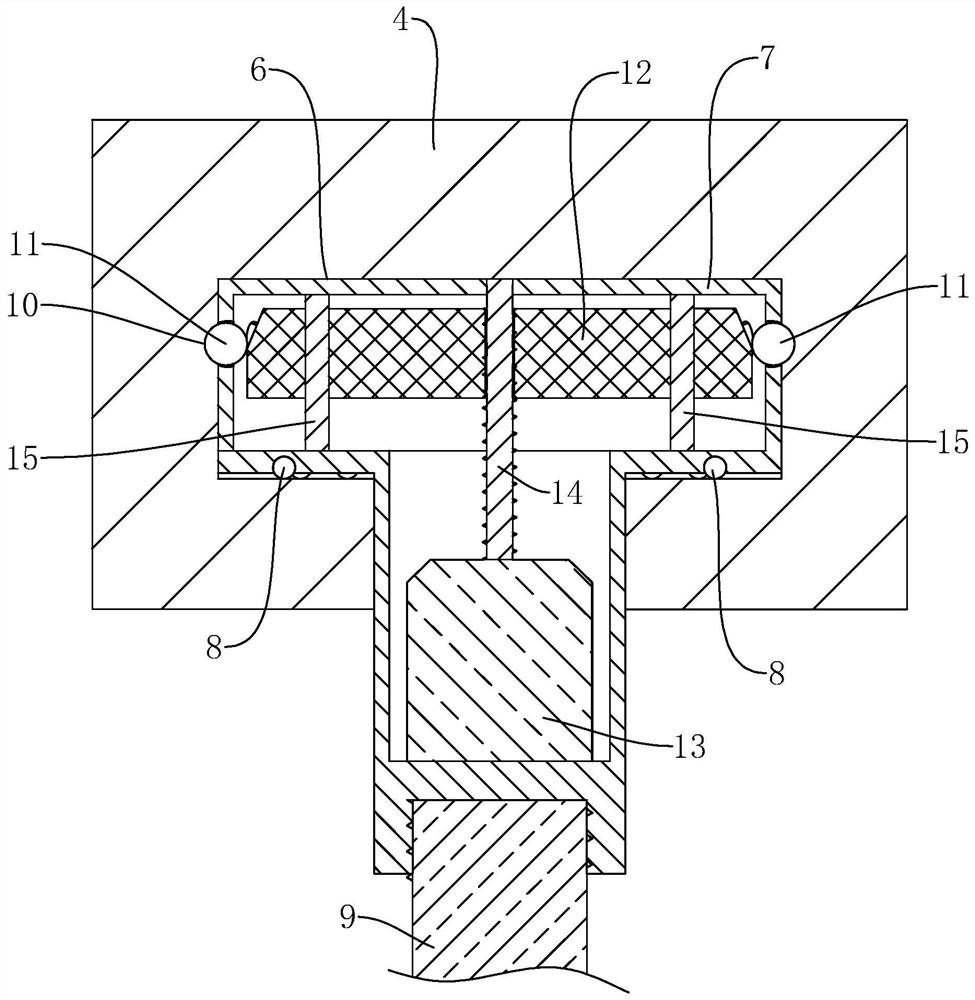

[0034] Such as image 3 As shown: the guide rail 4, the connecting rail 18 and the extension rail 5 are all provided with a T-shaped chute 6, and the chute 6 is provided with a T-shaped sliding shell 7, and the cross section of the sliding shell 7 is circular. A plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com