Full-automatic saw blade cutting type numerical control processing equipment

A processing equipment and fully automatic technology, applied in metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problems of inability to meet demand, high worker requirements, poor cutting accuracy, etc., to improve sawing accuracy and processing efficiency. , to ensure the cutting efficiency and improve the effect of cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

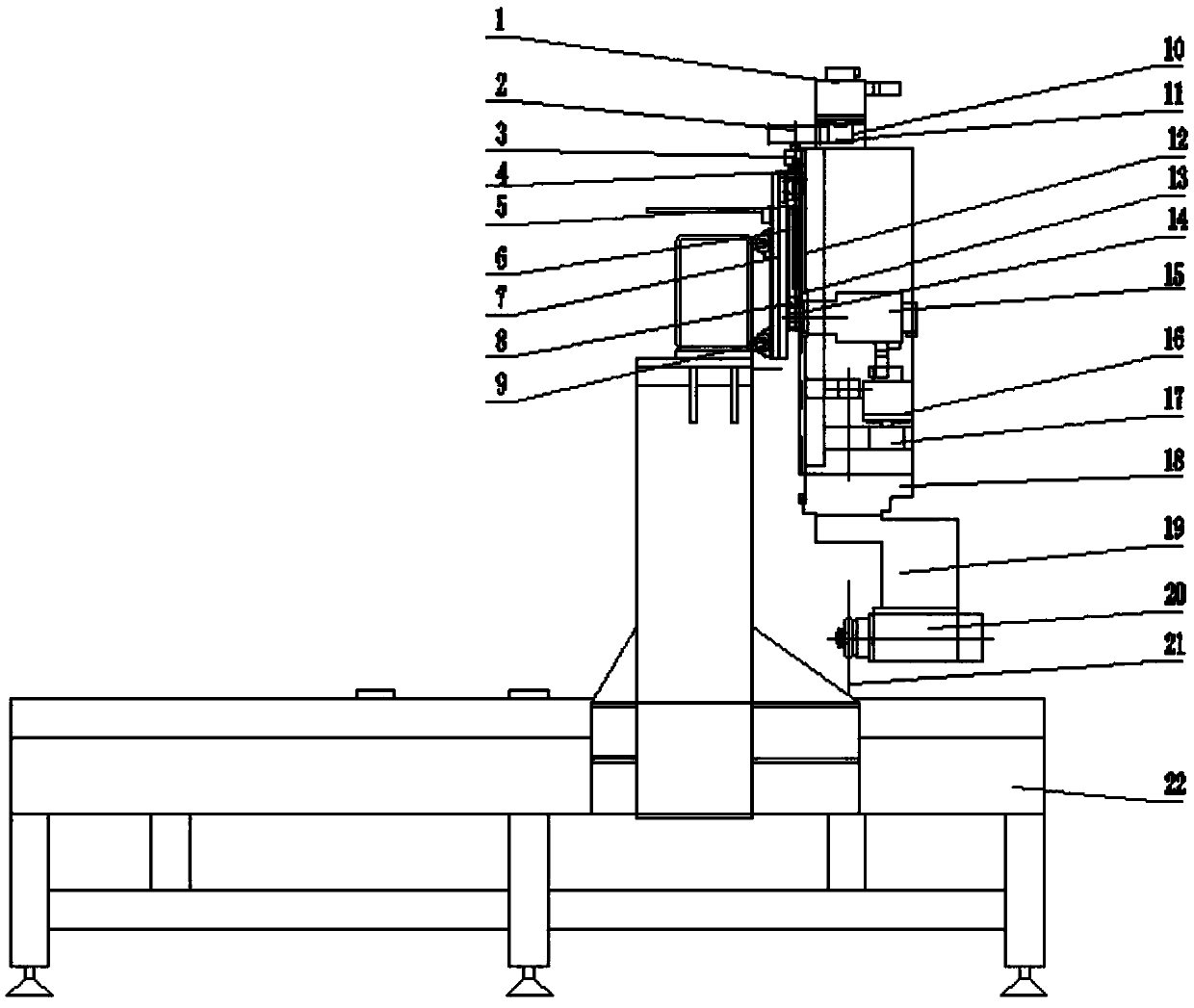

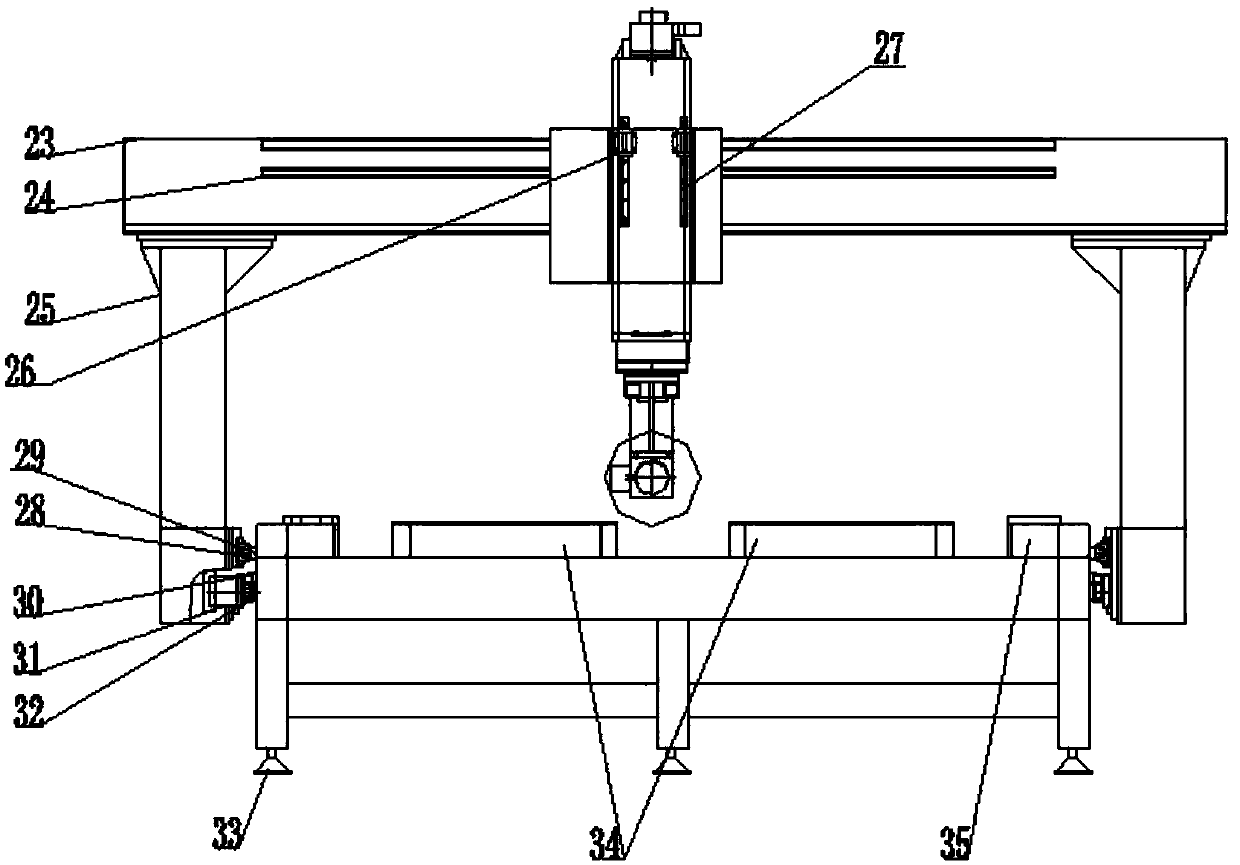

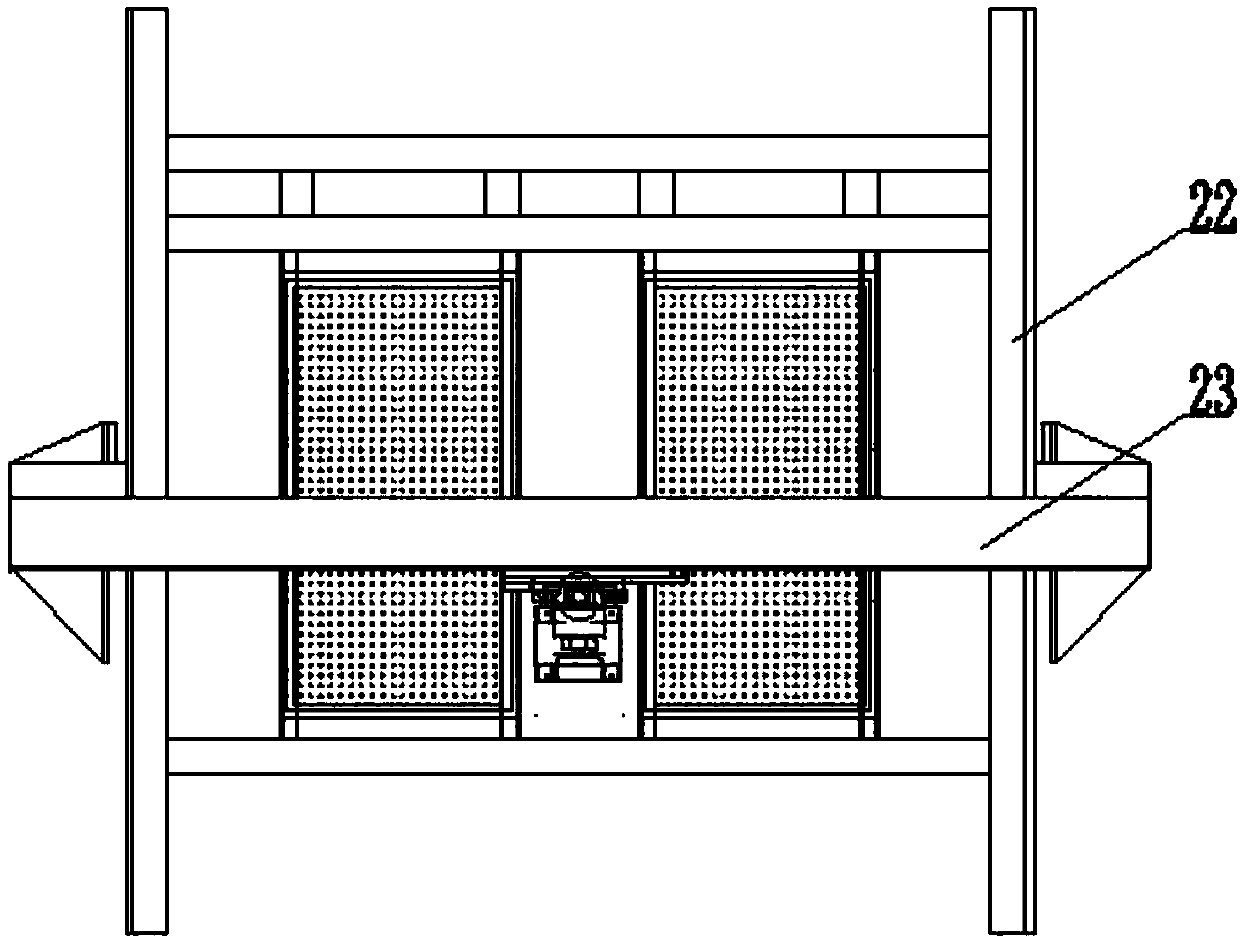

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, as shown in the figure: a fully automatic saw blade cutting numerical control processing equipment, including a bed 22, a beam 23 arranged above the bed 22, and a beam 23 installed on the The main shaft 20 on the top and the blade 21 arranged at the end of the main shaft 20, the two sides of the bed body 22 are symmetrically provided with side columns 25, and the two ends of the crossbeam 23 are respectively fixedly connected with the side column 25, and the crossbeam 23 The X-axis servo motor 15 that drives the main shaft 20 to move along the X-axis direction is installed on the top, and the Y-axis servo motor 31 that drives the side column 25 to move along the Y-axis direction is installed on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com