Plane equipment cleaning robot

A technology for cleaning robots and equipment, applied to conveyors, mechanical conveyors, chemical instruments and methods, etc., can solve problems such as low production efficiency and difficult quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

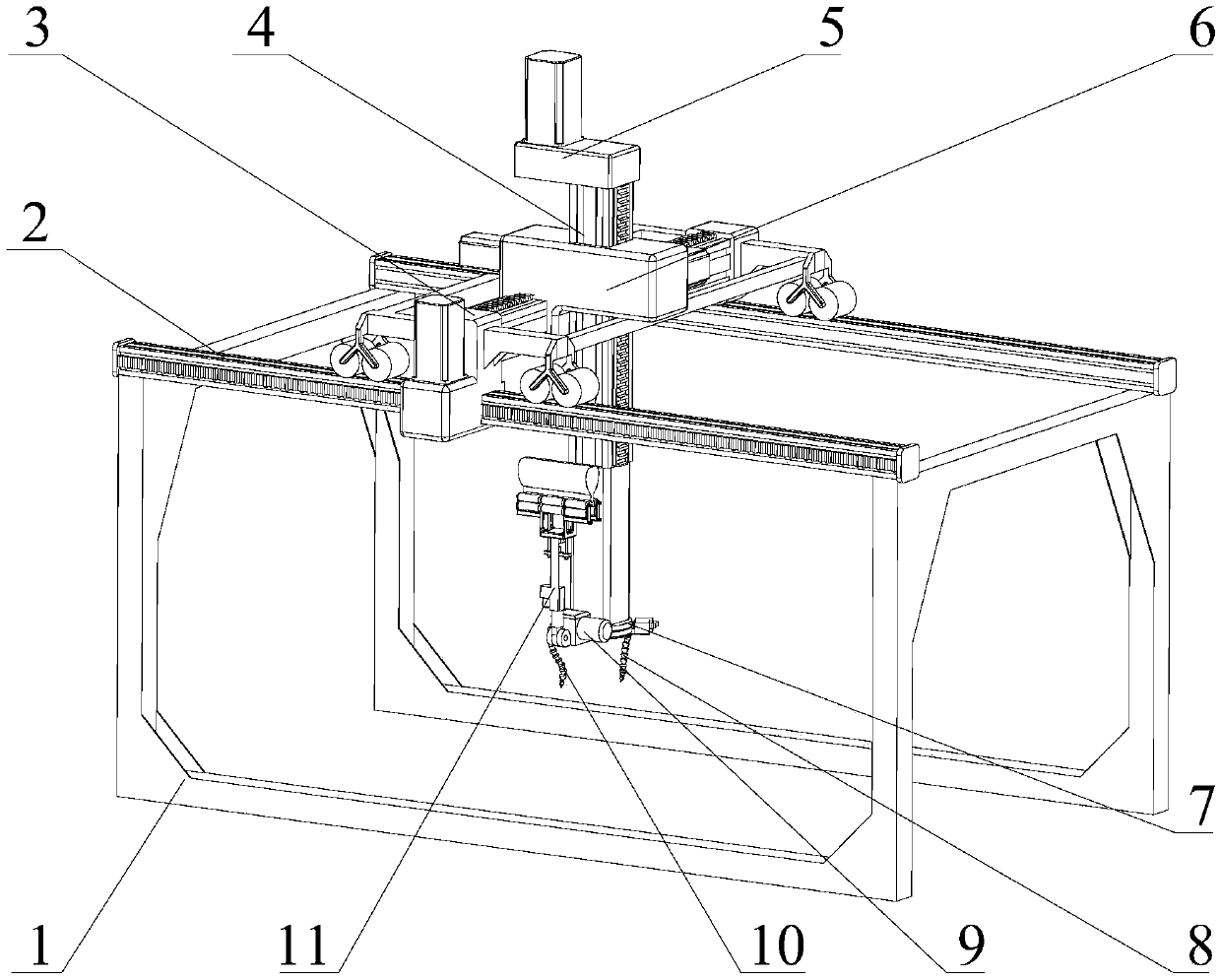

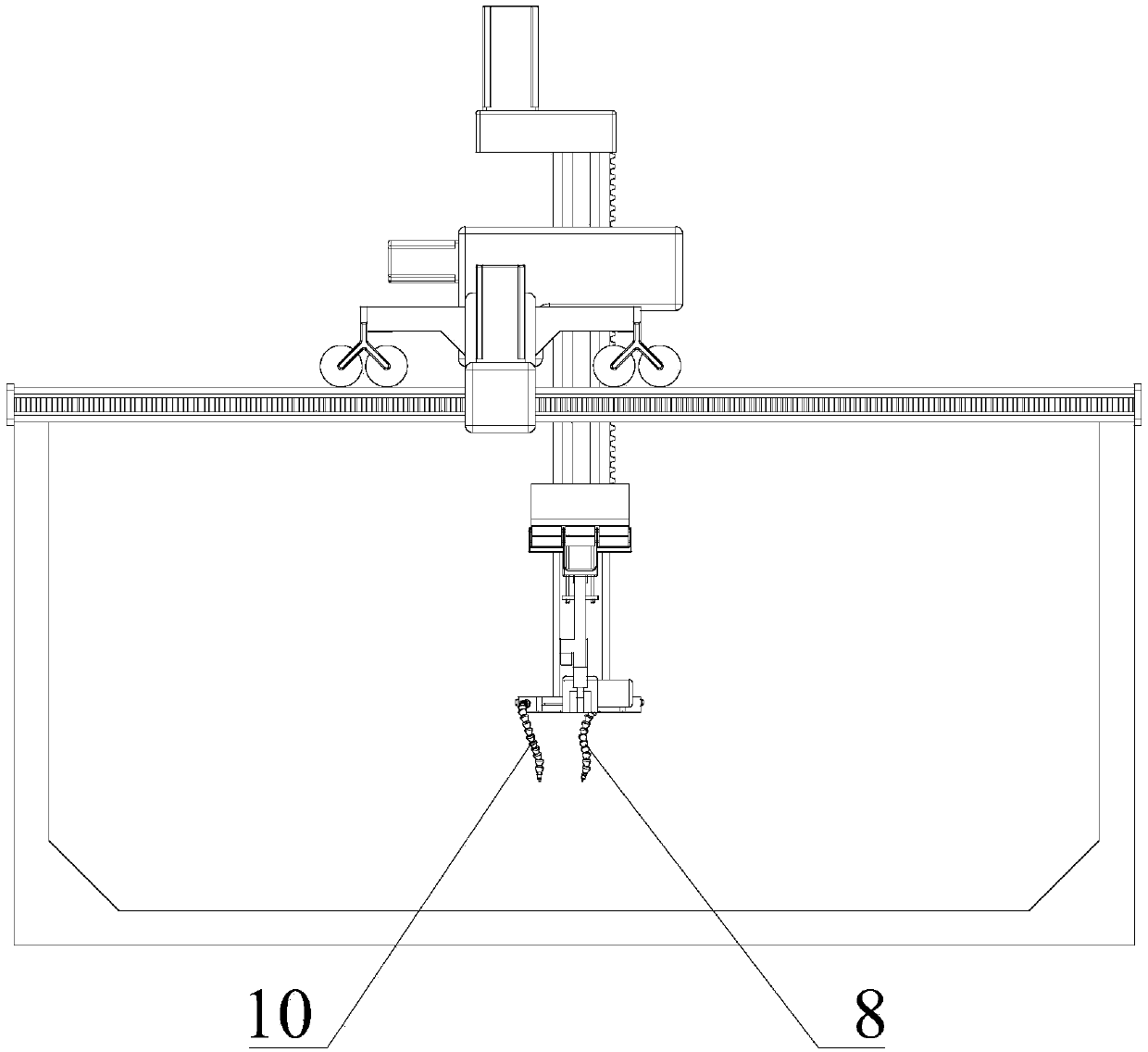

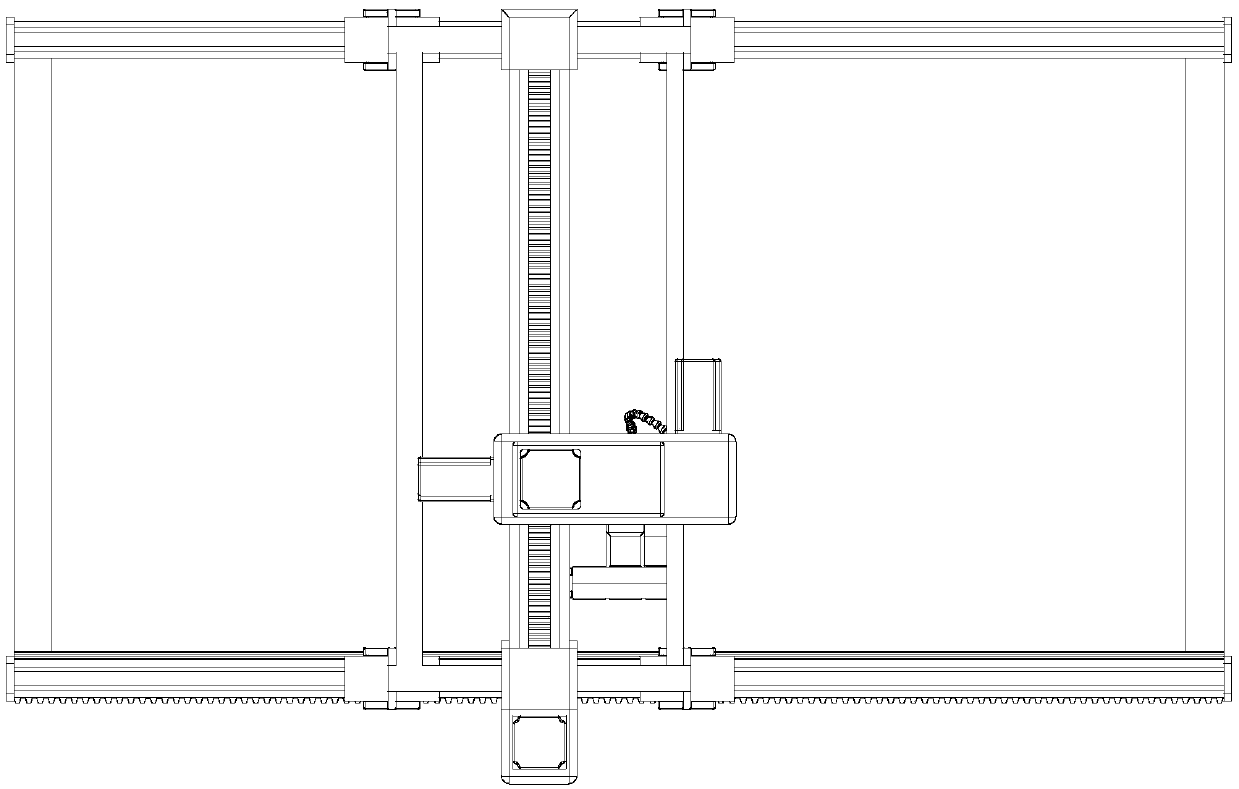

[0027] Embodiment 1: as Figure 1-12 As shown, a plane equipment cleaning robot includes a frame 1, an air jet liquid spray device I8, an air jet liquid spray device II10 and a Cartesian coordinate positioning mechanism; wherein the Cartesian coordinate positioning mechanism is fixed on the frame 1, and the air jet liquid spray device I8, The air-jet and liquid-jet device II10 is installed at the output end of the Cartesian coordinate positioning mechanism.

[0028] Further, the Cartesian coordinate positioning mechanism can be set to include X-guiding rail 2, Y-guiding rail 3, Z-guiding rail 4, reversing motor 5, horizontal positioning device 6, reversing flange 7, positioning motor I12-1, positioning Motor Ⅱ12-2, positioning motor Ⅲ12-3; among them, the X guide rail 2 is fixed on the frame 1 by bolts; the reducer I installed in the reducer I shell at the end of the Y guide rail 3 is fixed to the reducer by bolts Ⅰ The output shaft of the positioning motor Ⅰ12-1 on the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com