Closing-in type mud centrifugal equipment

A kind of centrifugal equipment, closed-mouth technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of damage, reduce the diameter of the outer cylinder, large size, etc., save volume space, avoid accumulation and solidification, use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

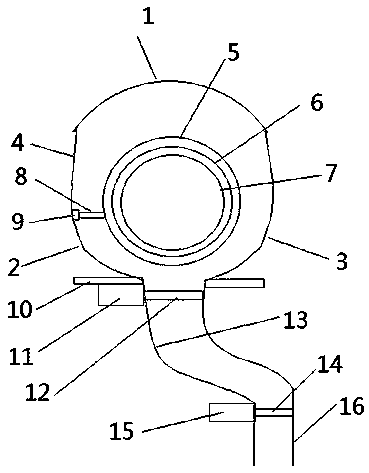

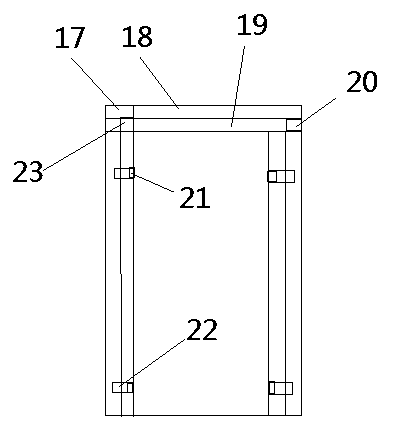

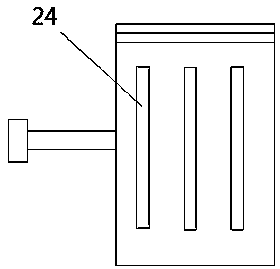

[0034] As shown in the figure: a closing type mud centrifugal equipment, including the first arc, the second arc, the third arc, the connecting section, the outer wall, the middle wall, the inner wall, the scraper rod, the scraper, the bracket, the first cylinder, the first gate Plate, mud-bearing arc wall, second ram, second cylinder, main body wall, multi-function tank, outer maintenance plate, inner maintenance plate, drain purge port, top wall of drain pipe, drain pipe, auxiliary blower Sweep port, mud discharge grill; the mud centrifugal equipment includes a centrifuge and a discharge valve, both of which are fixed on the bracket, the centrifuge includes an inner cylinder and an outer cylinder, and the outer cylinder includes a first arc , the second arc, the third arc, the connecting segment, the two ends of the first arc connect the second arc an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com