Preparation method of atomization component and electronic cigarette atomizer

An electronic cigarette atomizer and atomization component technology, which is applied in the field of electronic cigarettes, can solve the problems of insufficient stability of the printed heating element, limited e-liquid conduction and atomization efficiency, etc., achieves printing flatness and good bonding stability, eliminates The resistance floating is unstable and the effect of improving the conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] S10, selecting a tungsten steel sheet with a flat surface as the substrate S;

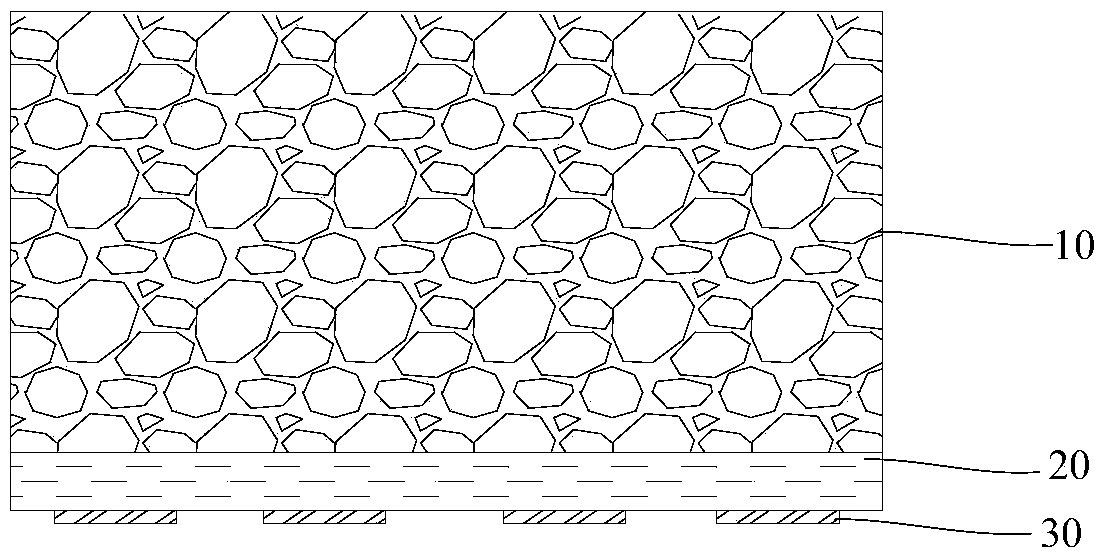

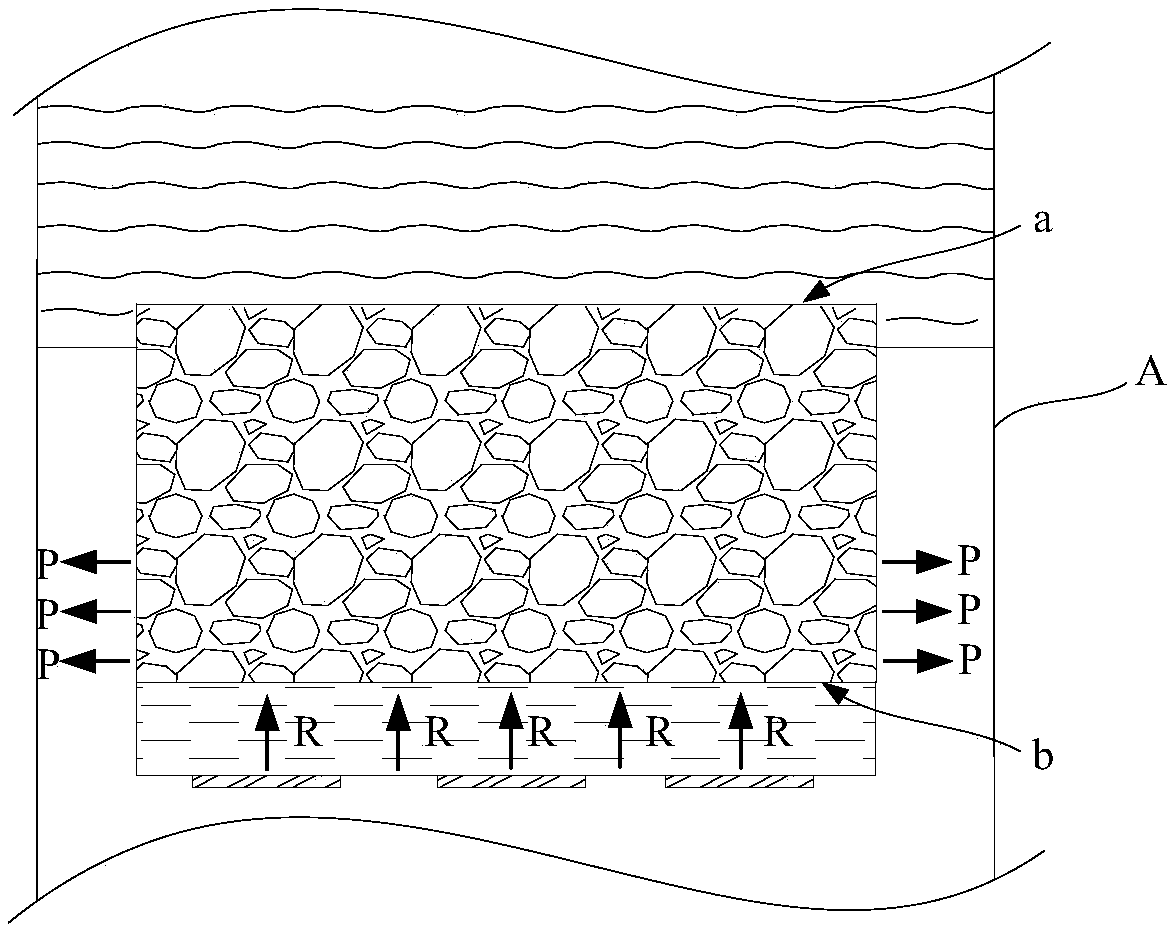

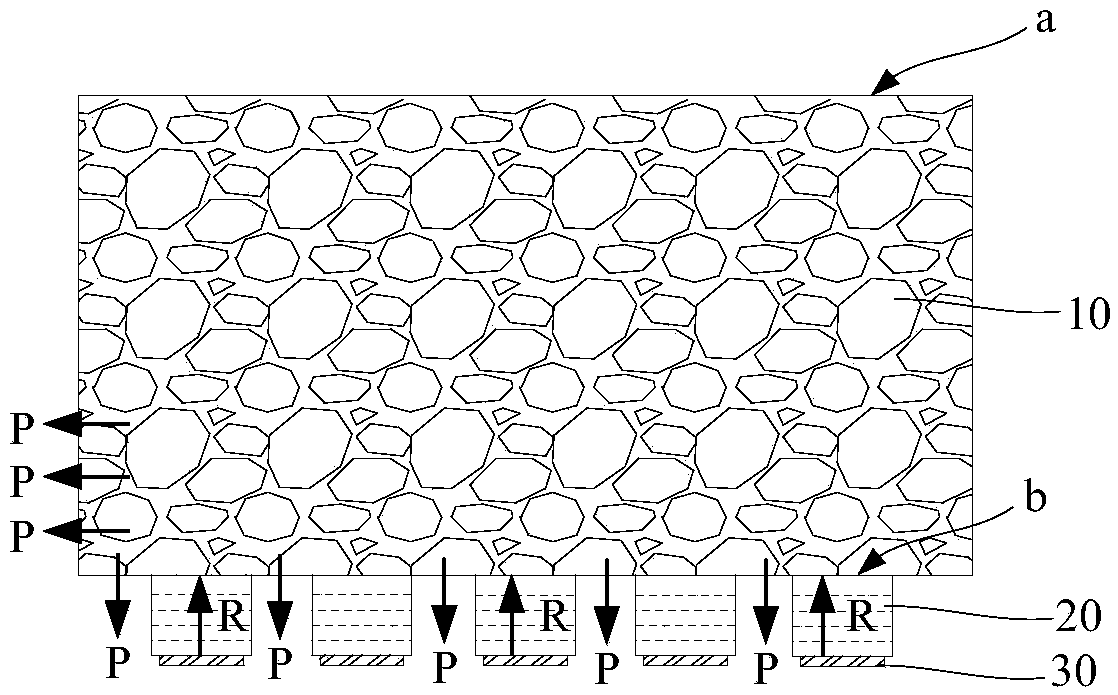

[0082] S21, use the alumina powder with an average particle size of 1 μm obtained through ball milling as a dense ceramic printing powder, add 2wt% printing spray adhesive (commercially available) and mix evenly, according to Figure 6 As shown, a 0.08 mm dense ceramic flooding body layer 20a is generated by 3D printing on the substrate;

[0083] S22, mix aluminum carbide and alumina powders with an average particle size of 20 μm and PMMA microspheres of 30 μm in a volume ratio of 1:1 as a porous ceramic printing powder, and then add 2wt% printing adhesive (commercially available) Purchase) mix well, according to Figure 7 The porous ceramic matrix layer 10a with a thickness of 5mm is continuously 3D printed on the dense ceramic matrix layer 20a to obtain the printed model;

[0084] S40, heat up the substrate S containing the printed model generated in step S30 from room temperature to 800...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com