A non-destructive pre-ripening method for red beans

A pre-curing and red bean technology, applied in food heat treatment, food science and other directions, can solve the problems of high energy consumption and cost, difficult to cook, fade and other problems, and achieve the effect of improving the use value of the technology, facilitating storage and transportation, and having no form expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

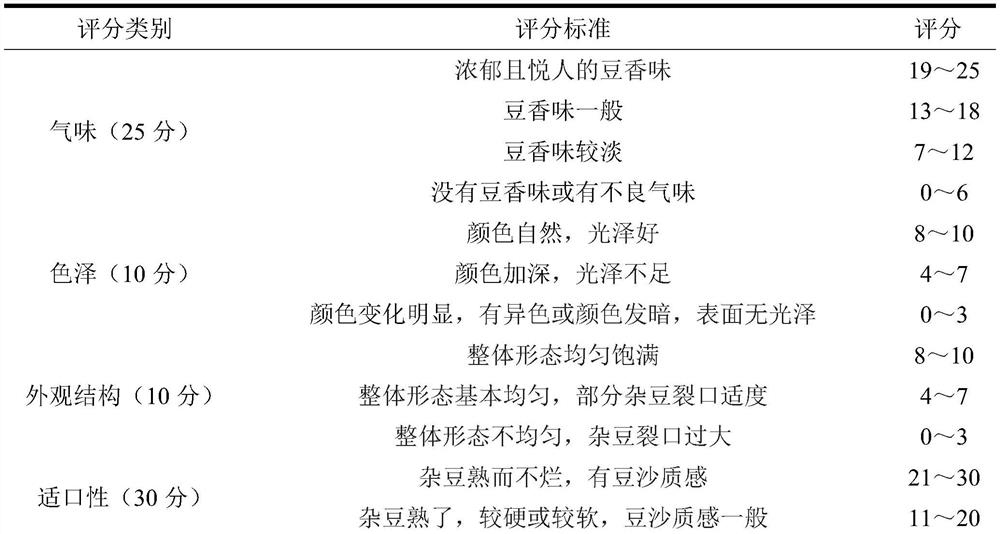

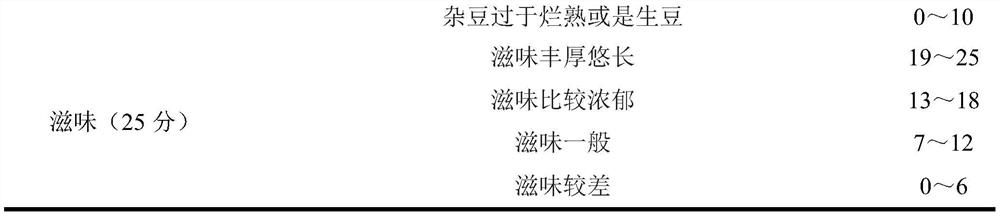

Examples

Embodiment 1

[0045] Embodiment 1 A kind of non-destructive pre-ripening method for red beans

[0046] 1) Wash 1 kg of red beans in clean water for 3 times, quickly drain and place them in a constant temperature and humidity chamber, spray 500 mL of clean water every half hour, and spray 10 times until the red beans are wet to 70% water.

[0047] 2) Put the product obtained in step 1) in the raw material tank, heat up to 80° C., increase the pressure to 0.15 MPa higher than the atmospheric pressure outside the raw material tank, keep the heat and pressure for 4 hours, so that the surface temperature of the red beans is consistent with the temperature in the raw material tank;

[0048] 3) Reduce the internal pressure of the raw material tank containing the product obtained in step 2) to a vacuum state and lower the temperature to 60° C. in a vacuum state, keep the temperature for 4 hours, then restore the pressure to atmospheric pressure, and repeat vacuuming 8 times;

[0049] 4) On the prem...

Embodiment 2

[0051] Embodiment 2 A kind of non-destructive pre-ripening method for red beans

[0052] 1) Wash 1 kg of red beans in clean water for 3 times, quickly drain and place them in a constant temperature and humidity chamber, spray 500 mL of clean water every half hour, and spray 10 times until the red beans are wet to 70% water.

[0053] 2) Put the product obtained in step 1) in the raw material tank, heat up to 70°C, increase the pressure to 0.15 MPa higher than the atmospheric pressure outside the raw material tank, keep the heat and pressure for 3 hours, so that the surface temperature of the red beans is consistent with the temperature in the raw material tank;

[0054] 3) Reduce the internal pressure of the raw material tank containing the product obtained in step 2) to a vacuum state and lower the temperature to 50°C in the vacuum state, keep the pressure for 4 hours, and then restore the pressure to atmospheric pressure, and repeat the vacuuming 8 times;

[0055] 4) On the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com