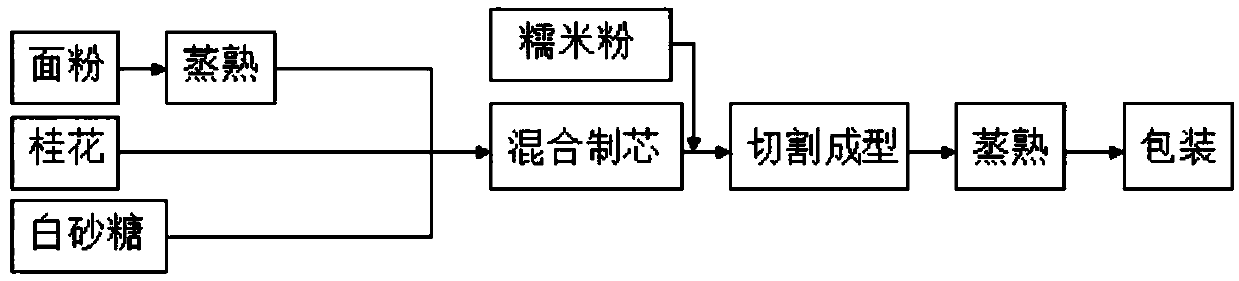

Method for making high-dietary fiber osmanthus jelly

A production method and technology of sweet-scented osmanthus cake are applied in the field of food processing, can solve problems such as low efficiency, and achieve the effect of increasing the content of soluble dietary fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

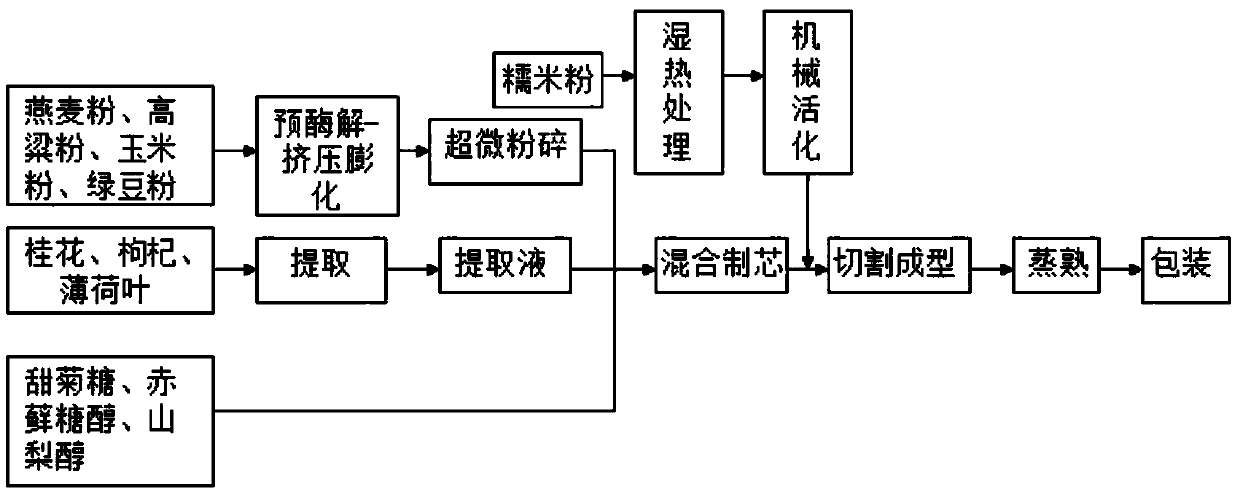

Method used

Image

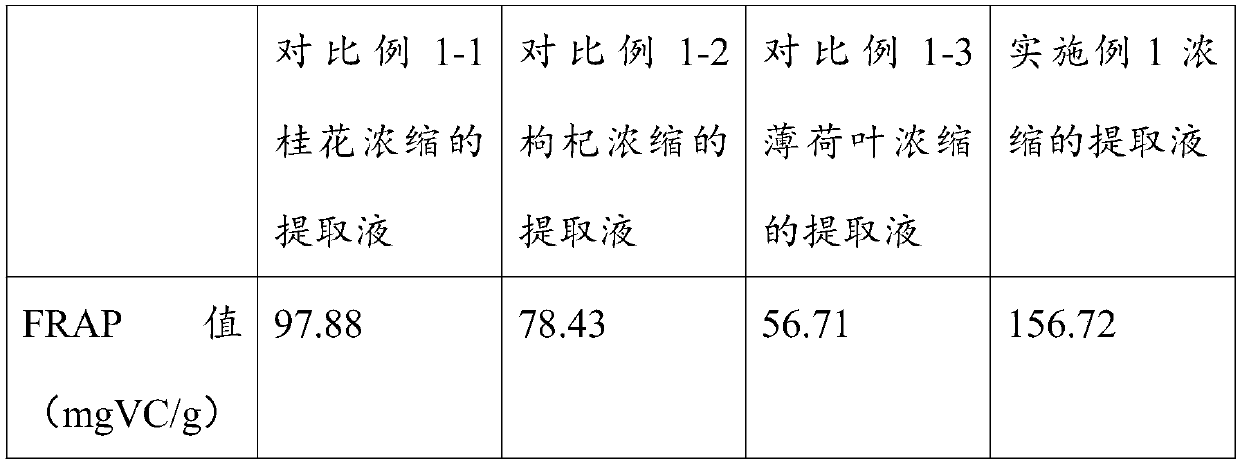

Examples

Embodiment 1

[0032] (1) Mix oat flour, sorghum flour, corn flour, and mung bean flour (all purchased from Lianhua Supermarket, the same as other examples) in a mass ratio of 1:1:0.5:2 to obtain miscellaneous grain flour; add 30U / g of High temperature-resistant α-amylase (purchased from Shandong Anke Bioengineering Co., Ltd., the same as other embodiments) and 10U / g pullulanase (purchased from Henan Yangshao Biochemical Engineering Co., Ltd., the same as other embodiments), wherein α-amylase The quality of enzyme and pullulanase is respectively 2% and 0.5% of miscellaneous grain powder, add water to make moisture mass content be 15% of miscellaneous grain powder, activate at 34 ℃ for 50 minutes, adjust moisture mass content to 15% in the material, inject In the twin-screw extrusion extruder, the temperatures at the front end, middle end, and end of the extruder are 40°C, 90°C, and 130°C respectively, the screw speed is 100r / min, and the feeding speed is 10r / min to obtain rod-shaped semi-fini...

Embodiment 2

[0052] (1) Mix oat flour, sorghum flour, corn flour, and mung bean flour in a mass ratio of 1:1.2:0.8:2.5 to obtain miscellaneous grain flour; add 35U / g of high-temperature resistant α-amylase and 15U / g of pullulan Enzymes, wherein the quality of α-amylase and pullulanase is 2.5% and 1% of the miscellaneous grain powder respectively, add water to make the moisture content 20% of the miscellaneous grain powder, activate at 35°C for 55 minutes, and adjust the moisture content in the material To 18%, injected in the twin-screw extrusion extruder, extruder front end, middle end and end temperature are respectively 45 ℃, 100 ℃, 135 ℃, screw speed is 110r / min, feed speed is 20r / min, obtains Rod semi-finished products, dry;

[0053] (2) The dried semi-finished product is ultrafinely pulverized using a jet mill, the motor speed is 2500r / min, and the feeding speed is 4kg / h to obtain high dietary fiber miscellaneous grain powder;

[0054] (3) Mix sweet-scented osmanthus, wolfberry, and...

Embodiment 3

[0072] (1) Mix oat flour, sorghum flour, corn flour and mung bean flour in a mass ratio of 1:1.5:1:3 to obtain miscellaneous grain flour. Add 40U / g of high-temperature-resistant α-amylase and 20U / g pullulanase, wherein the quality of α-amylase and pullulanase is 3% and 1.5% of the miscellaneous grain powder respectively, adjust the moisture, add water to make the moisture quality The content is 25% of miscellaneous grain powder, activated at 38°C for 60 minutes, adjust the moisture content in the material to 20%, and inject it into the twin-screw extrusion extruder. ℃, 145℃, the screw speed is 120r / min, the feeding speed is 30r / min, and the rod-shaped semi-finished product is obtained and dried;

[0073] (2) The dried semi-finished product is ultrafinely pulverized using a jet mill, the motor speed is 3000r / min, and the feeding speed is 6kg / h to obtain high dietary fiber miscellaneous grain powder;

[0074] (3) Mix sweet-scented osmanthus, wolfberry, and mint leaves in a mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com