Coil-shaped thermoelectric unit, fabric structure thermoelectric device and preparation and application thereof

A thermoelectric device, coil-shaped technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device parts, etc., can solve the problems of complex preparation, poor wearability, good wearability, etc., and achieve good bidirectional stretching performance and output High power density and good wearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

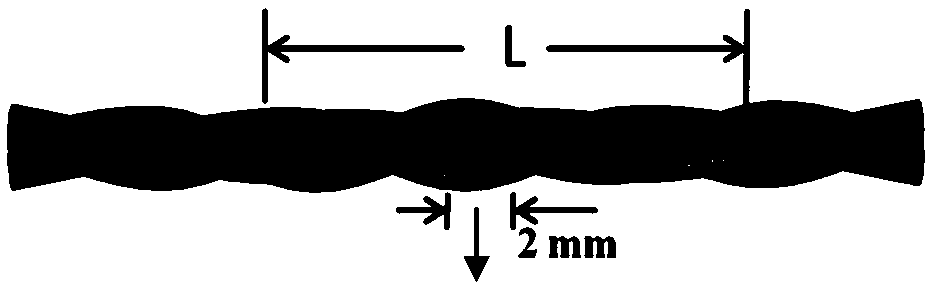

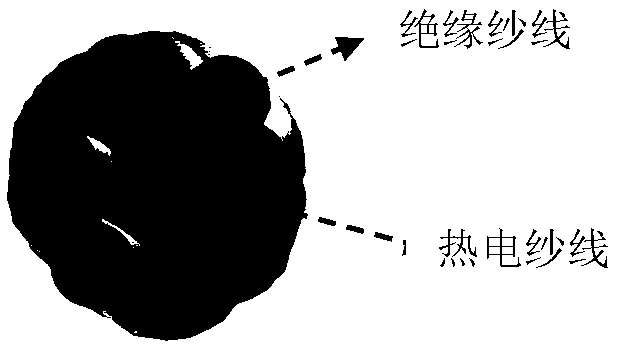

[0048] The coil-shaped thermoelectric unit is constructed of carbon nanotube yarns containing P-type segments, N-type segments, and electrode segments through interspersed interval wrapping and bending. The P-type segment is made of carbon nanotube yarns mixed with amine It is obtained by impregnation and doping with impurity agents, and the P-type segment is obtained by impregnating and doping carbon nanotube yarns through PEDOT:PSS. The P-type segment and the N-type segment are located at the coil position of the coil, and the electrode segment is located at the coil arc position of the coil. The coils are connected in series to form a weft row, and the first row arc is placed above the second row. The row arc is placed under the third row column, which is a cycle, and every two subsequent rows are a cycle, and the cycle configuration is repeated in turn, and the elastic relationship between the curved yarns (coils) is cleverly used to make the coils stand upright on their ow...

Embodiment 2

[0061] The coil-shaped thermoelectric unit is constructed of carbon nanotube yarns containing P-type segments, N-type segments, and electrode segments through interspersed interval wrapping and bending. The P-type segment is made of carbon nanotube yarns mixed with amine It is obtained by impregnation and doping with impurity agents, and the P-type segment is obtained by impregnating and doping carbon nanotube yarns through PEDOT:PSS. The P-type segment and the N-type segment are located at the coil position of the coil, and the electrode segment is located at the coil arc position of the coil. The coils are connected in series to form a weft row, and the first row arc is placed above the second row. The row arc is placed under the third row column, which is a cycle, and every two subsequent rows are a cycle, and the cycle configuration is repeated in turn, and the elastic relationship between the curved yarns (coils) is cleverly used to make the coils stand upright on their ow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com