Multi-camera array-based large-size industrial plate online measurement system and method

A measurement method and camera array technology, applied in image data processing, instrumentation, calculation, etc., can solve problems affecting splicing accuracy, target edge distortion, high equipment cost, etc., and achieve the goal of improving image accuracy, weakening false edges, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

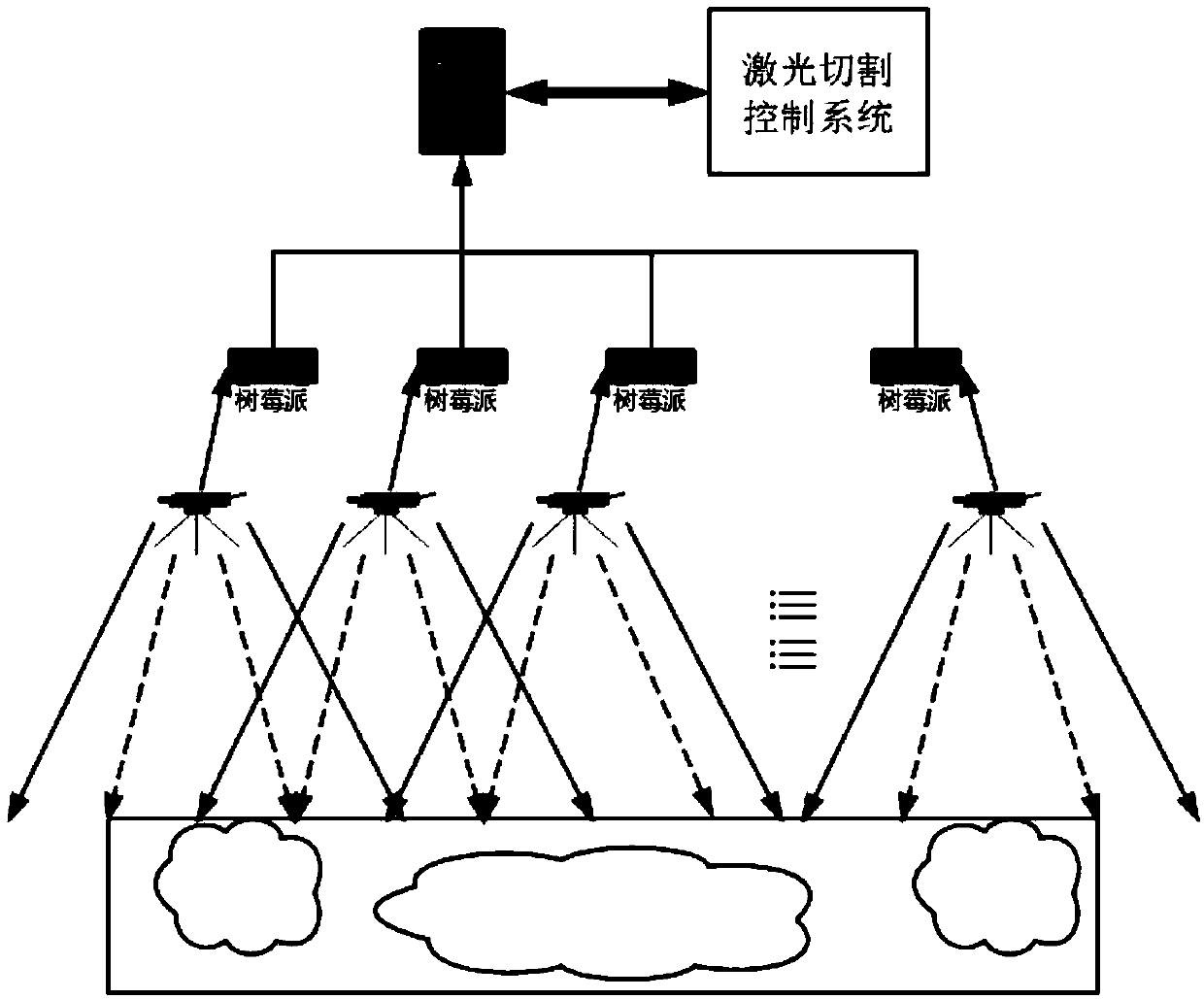

[0048] like figure 1 Shown, an on-line measurement system for large-scale industrial sheets based on a multi-camera array, including:

[0049] Image acquisition module, self-adaptive camera array, ordinary monocular camera can obtain local high-resolution images of the plate;

[0050] The preprocessing module uses a Raspberry Pi processor to establish distributed processing subsystems of each monocular acquisition system. Each subsystem implements local image preprocessing at the end, including image denoising, distortion correction, and feature extraction of image targets. and local measurement, etc.;

[0051] The image feature integration module uses adaptive Harris corner matching algorithm and contour matching algorithm to achieve fast global image splicing and accurate segmentation of multiple targets according to the image edge features of each subsystem.

[0052] The preprocessing module is used to control the image acquisition of the distributed processing subsystem ...

Embodiment 2

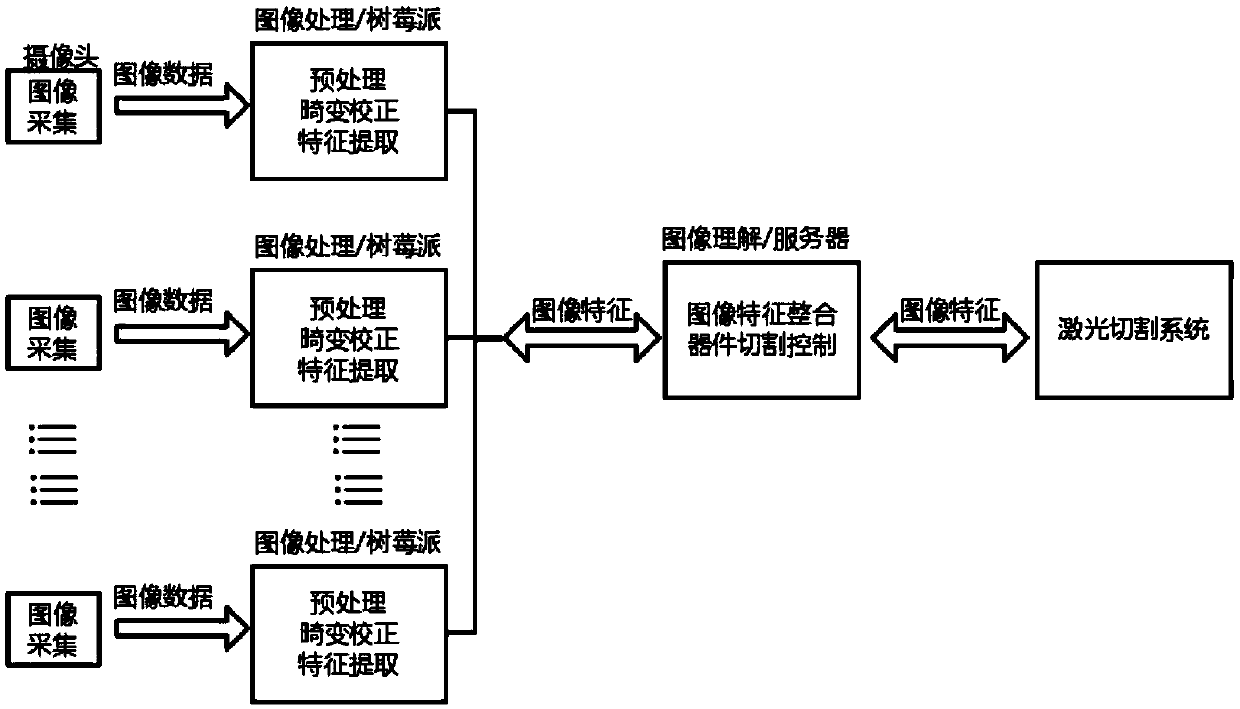

[0060] like figure 2 As shown, an on-line measurement method for large-size industrial plates based on a multi-camera array includes the following steps:

[0061] S1. Build an embedded camera array according to the industrial sheet shape and target size;

[0062] S2. Use ARM to control a common monocular camera to collect local high-resolution images of the plate;

[0063] S3. Use embedded technology to achieve feature extraction and local measurement of local high-resolution image targets;

[0064] S4. According to the target edge feature of the local image, image stitching is performed, the global image is reconstructed, and the geometric size of the industrial plate and the accurate segmentation of multiple targets are calculated.

[0065] In this specific implementation, the local image understanding information is integrated and processed on the embedded system to obtain the overall image understanding information of the device, including the shape, area and edge infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com