Device for realizing two-side temperature field environment test of test element

An environmental test device and test piece technology, applied in the direction of measurement device, strength characteristics, instruments, etc., can solve the problems of slow heat conduction of plexiglass, affecting the mechanical properties of the transparent parts of the cockpit cover, and the lack of finished products in the high and low temperature comprehensive environmental test system. Satisfy the effect of strength, moderate weight and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

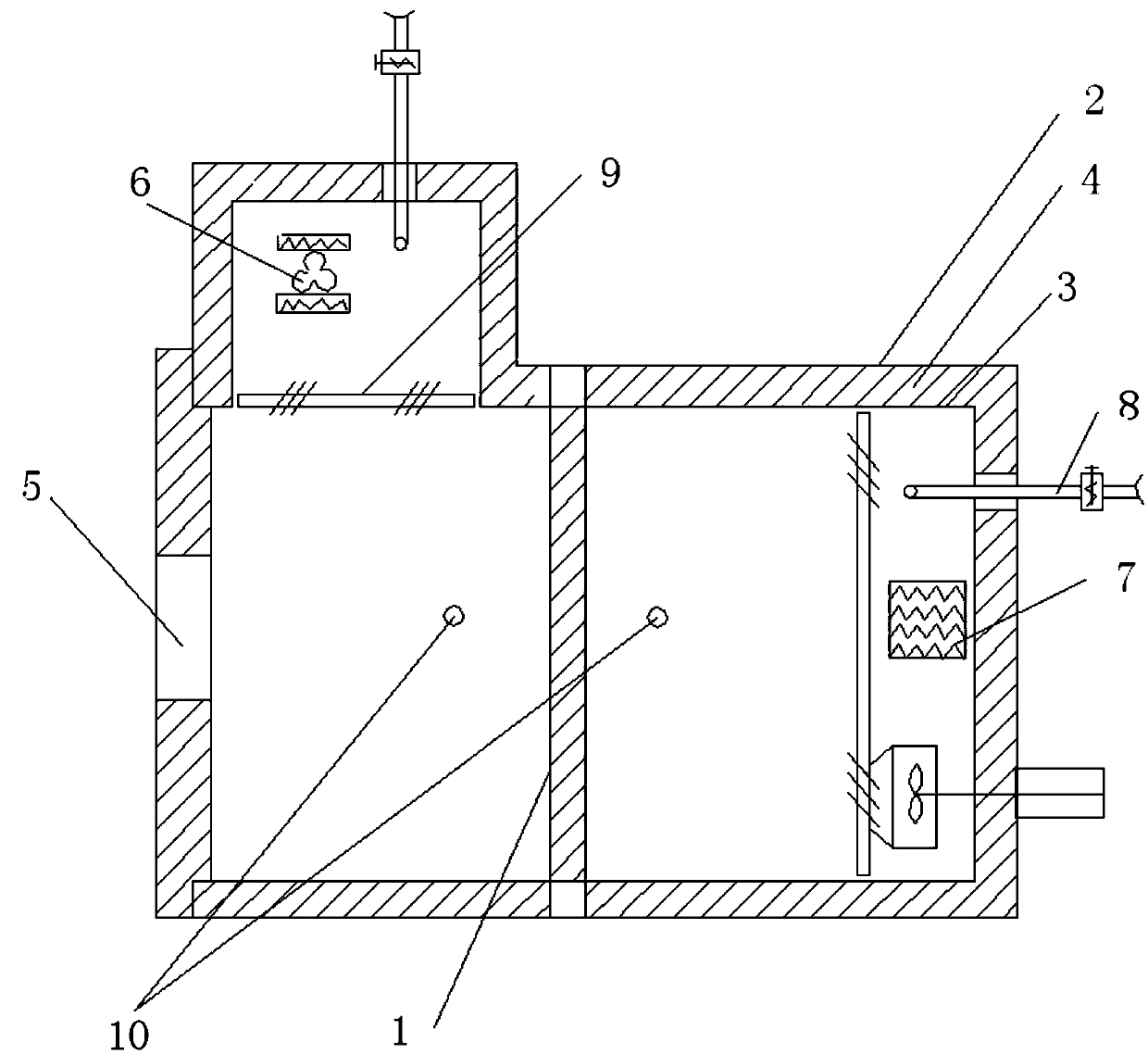

[0011] See attached Figure 1-3 , an environmental test device for realizing the temperature field on both sides of the test piece, which consists of two parts: a box body and a control system; the box body is a butt joint split structure, consisting of an outer shell (2), an inner tank (3), and a heat insulating layer (4) , to ensure a constant temperature in the box; the whole box is divided into two independent areas by the middle partition (1), and the middle partition (1) is shaped according to the shape of the sample and the fixture by the heat insulating material with good plasticity; the control system It consists of a fan system (6), a heating facility (7), a cooling facility (8), an air deflector (9), and a temperature sensor (10), and is used to control the temperature environment of two independent areas in the cabinet.

[0012] On the basis of the above device, the shell (2) is made of thin steel plate and painted; the inner tank (3) is made of stainless steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com