Automatic temperature and voltage control LED lamp strip

A technology of LED light strips and LED lamp beads, which is applied in the direction of lighting and heating equipment, electrical components, semiconductor devices of light-emitting components, etc., can solve the problems of high cost, stand out, and shorten lifespan, so as to ensure normal service life and temperature Maintain normal and guarantee the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

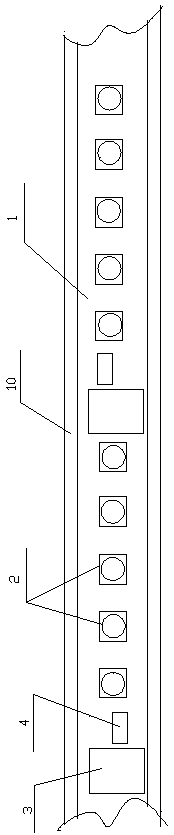

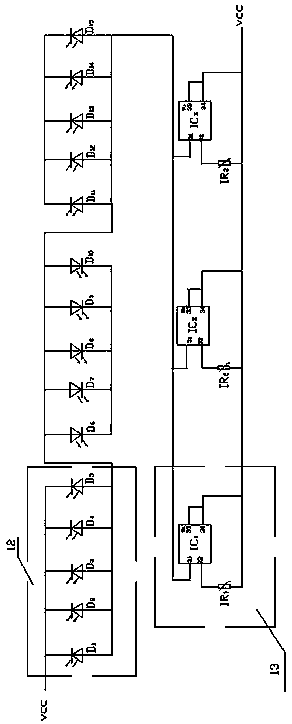

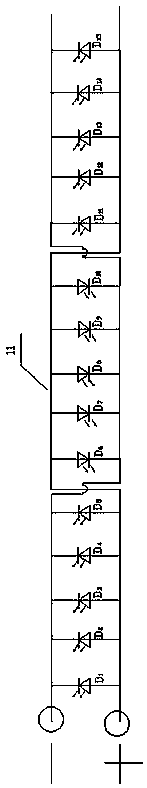

[0013] The structure and technical solutions described in the present invention will be further elaborated and explained below in conjunction with the accompanying drawings: the automatic temperature and pressure control LED light strip of the present invention includes a flexible shell 10, a flexible circuit board 1 and LED lamp beads 2, The positive and negative connection lines of the installation circuit 11 of the LED lamp beads 2 on the flexible circuit board 1 are arranged linearly and interlaced in stages, and N parallel LED lamp beads 2 are installed on the installation circuit 11, and each N parallel connection The LED lamp beads 2 form a light-emitting unit circuit 12, and M light-emitting unit circuits 12 are installed in series on the flexible circuit board 1;

[0014] refer to figure 1 , figure 2 , image 3 In the present invention, since the installation circuit composed of the positive and negative terminal connecting lines of the LED lamp beads on the flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com