Anchor pile method static load test detecting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

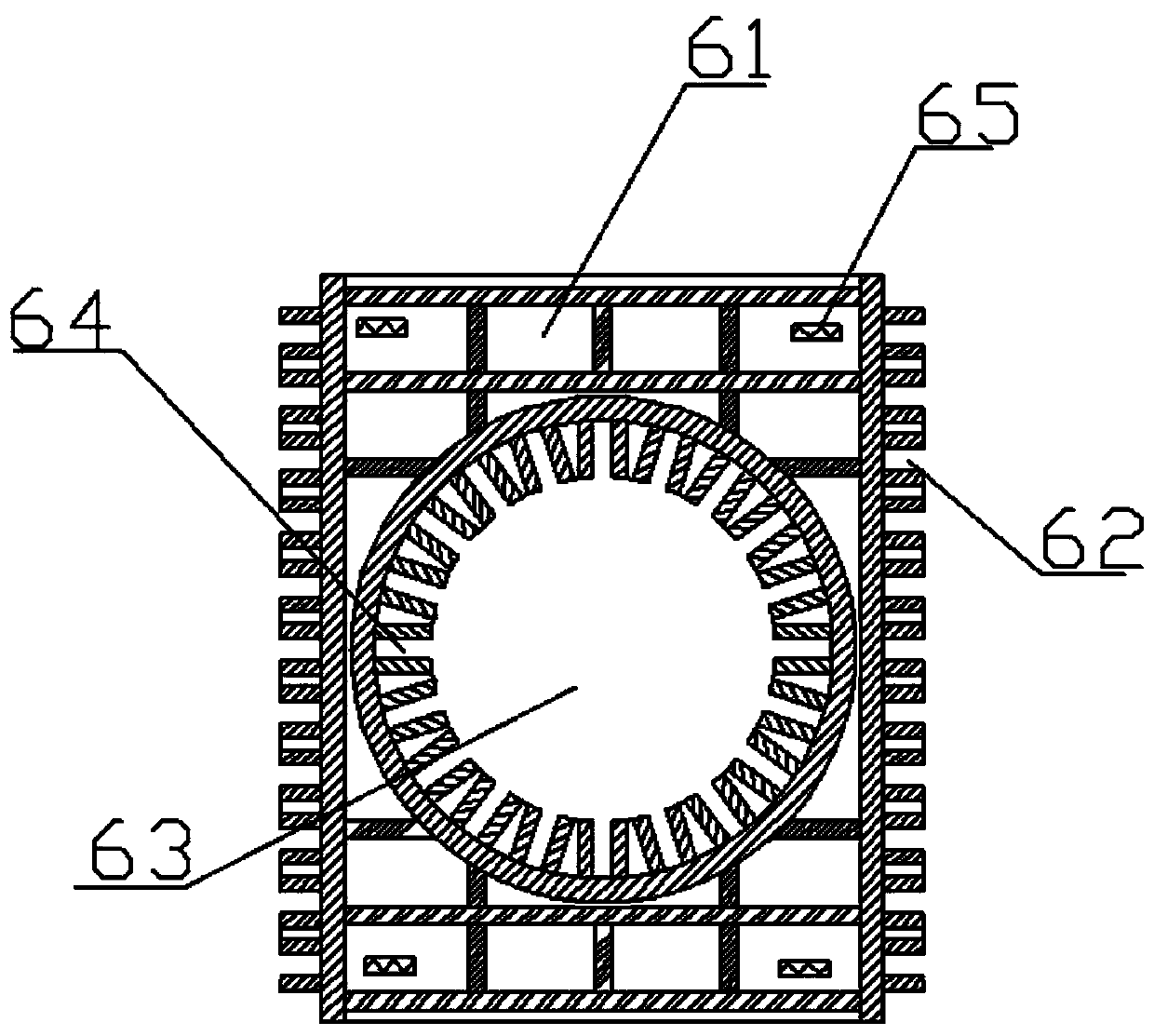

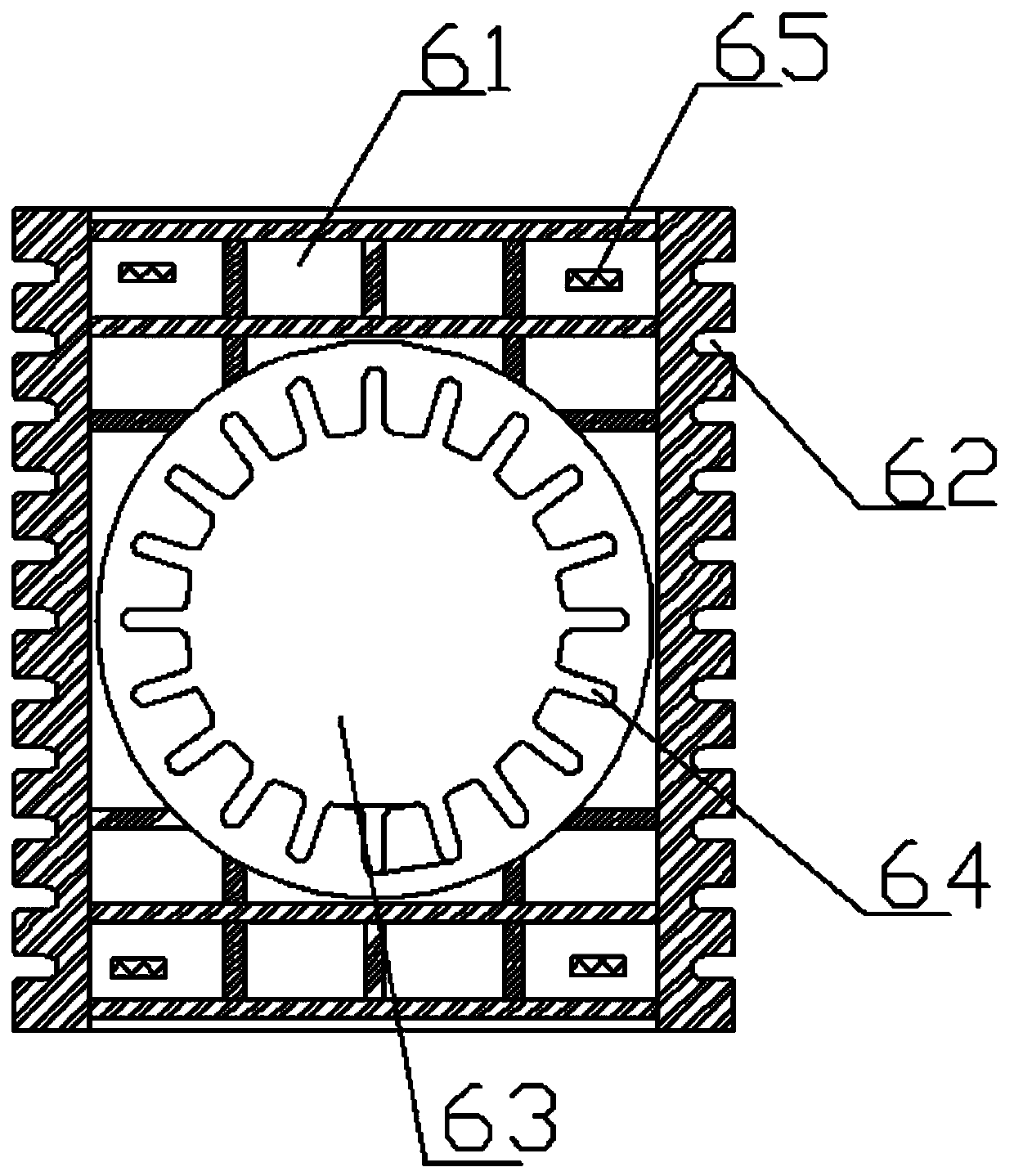

[0027] like figure 1 , 2 , shown in 4, 5, a kind of anchor pile method static load test detection device, comprises static load test pile 3, is located at the jack 12 above described static load test pile 3, and the top level of described jack 12 is provided with main girder 1. At least two secondary beams 2 perpendicular to the main beam 1 are arranged horizontally above the main beam 1, and the secondary beams 2 are symmetrically arranged on both sides of the jack 12, and each of the secondary beams Two anchor piles 4 are arranged directly below the anchor pile 2, and the anchor piles 4 are arranged symmetrically on both sides of the main beam 1; There is a row of parallel connecting rods 7, the connecting rods 7 are located on both sides of the secondary beam 2, and an anchor plate 6 is also arranged between the anchor pile 4 and the main beam 1, and the anchor plate 6 and the anchor A supporting member 5 is provided between the piles 4, and the anchor plate 6 includes a ...

Embodiment 2

[0032] like figure 1 , 3 , shown in 4, 5, a kind of anchor pile method static load test detection device, comprises static load test pile 3, is located at the jack 12 above described static load test pile 3, and the top level of described jack 12 is provided with main girder 1. At least two secondary beams 2 perpendicular to the main beam 1 are arranged horizontally above the main beam 1, and the secondary beams 2 are symmetrically arranged on both sides of the jack 12, and each of the secondary beams Two anchor piles 4 are arranged directly below the anchor pile 2, and the anchor piles 4 are arranged symmetrically on both sides of the main beam 1; There is a row of parallel connecting rods 7, the connecting rods 7 are located on both sides of the secondary beam 2, and an anchor plate 6 is also arranged between the anchor pile 4 and the main beam 1, and the anchor plate 6 and the anchor The pile 4 is provided with a support member 5, and the anchor plate 6 includes a cuboid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com