Deconstructed finite element assembled prestressed pile suitable for pile bottom hammering pile driving

A finite element, prestressed pile technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inconvenient transportation, affecting construction efficiency, and force loss, so as to achieve good quality of finished construction products and improve pile sinking efficiency , a high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that the orientation words "up, down, top, bottom" in the following embodiments are all described according to the drawings, and do not constitute limitations to the present invention.

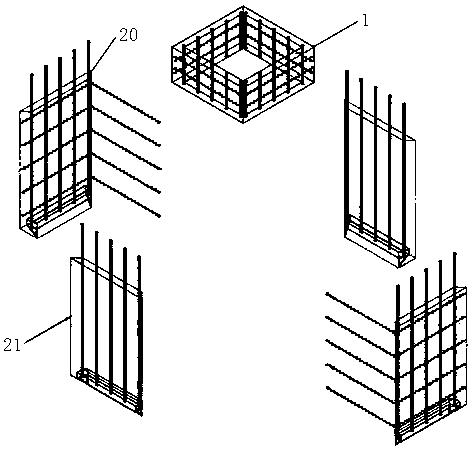

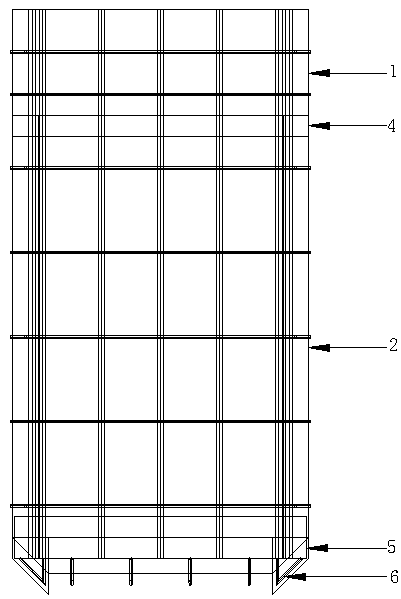

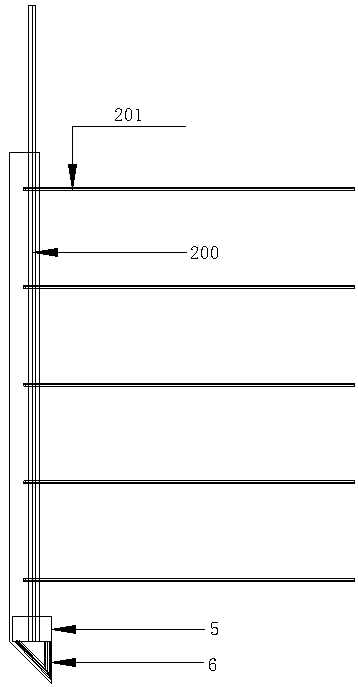

[0028] Attached below Figure 1-7 The present invention is described in further detail: as Figure 1-5 As shown, a deconstructed finite element assembled prestressed pile suitable for hammering piles at the bottom of the pile, the combined pile includes a pile body 2, a pile 1 and a sharp corner structure 6; the pile body 1 includes a pile body plate I20, a pile body plate Ⅱ21, and there are two respectively, longitudinal prestressed steel bars 200 are arranged at a certain interval in the longitudinal direction of the pile body plate I20, and protrude from the top of the pile body plate I20, and horizontal reinforcement bars 201 are arranged at a certain interval in the horizontal direction, and one side extends out of the pile body plate I20; The longitudinal prest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com