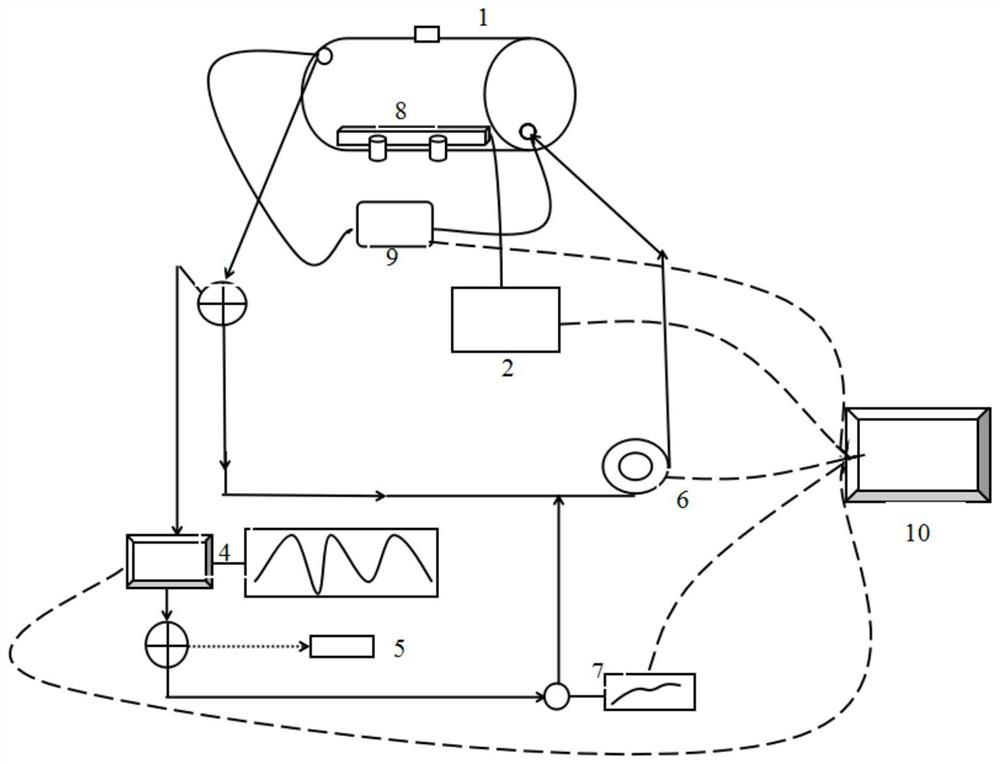

A system and method for rapidly maturing wine in an ultrasonic-coupled oak barrel

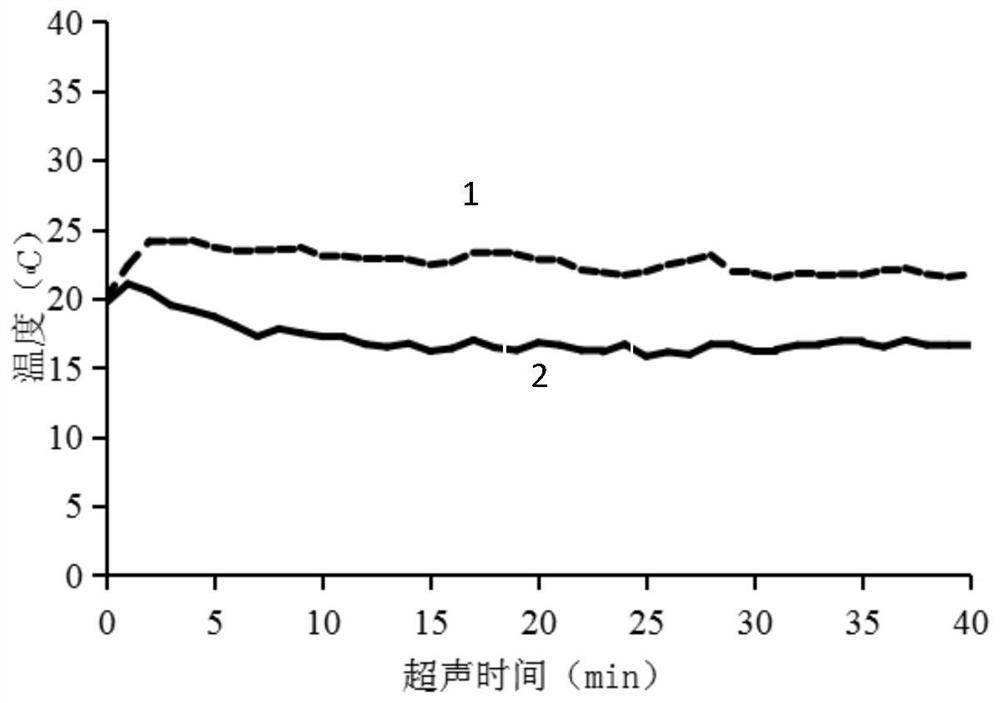

An oak barrel and ultrasonic technology is applied in the preparation of alcoholic beverages, material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials. Increase the labor intensity, the temperature of the wine body, etc., to achieve the effect of increasing the unique flavor of oak, speeding up the reaction speed, and avoiding excessive processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

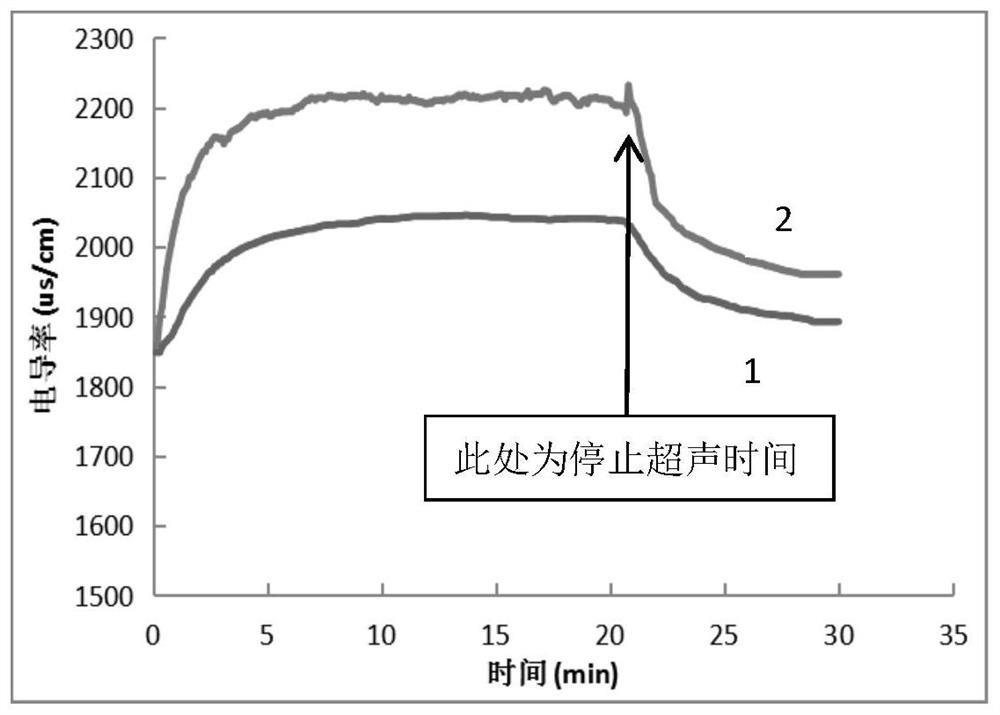

[0059] The difference from Embodiment 1 is that the spectral detection instrument 4 of the present embodiment is connected to the conductivity detection instrument 7 through a pipeline, and the conductivity detection instrument 7 is connected to the peristaltic pump 6 through a pipeline, that is, from the outflow from the spectral detection instrument 4. The wine liquid enters the conductivity detection instrument 7 through the pipeline to detect the conductivity and then returns to the wine liquid circulation pipeline through the peristaltic pump 6 .

[0060] Others are the same as in Example 1.

[0061] The effects of the aging method of the present invention, the natural aging process and the conventional ultrasonic treatment process on the color correlation value of the wine sample, the comprehensive sense of the wine sample, and the polyphenol content in the wine sample are compared, and the results are as follows. Figure 4 , 5 , 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com